Tracing the path of triethylene glycol monoethyl ether takes us deep into the twentieth-century expansion of industrial chemistry. Chemists once stumbled onto its synthesis through the push to expand the ether family, mainly hunting for solvents that did more than just mix with water. As industries searched for compounds that could handle metals and plastics better, this glycol ether found attention thanks to both its chemical flexibility and lower toxicity compared with older, riskier solvents like benzene or chloroform. Early makers saw potential, wanting something less volatile for paints, inks, and cleaning agents. That idea stuck, and as technology advanced, the ether found itself in more specialized roles, especially in cleaning electronics, preparing formulations in labs, and handling sensitive industrial additives.

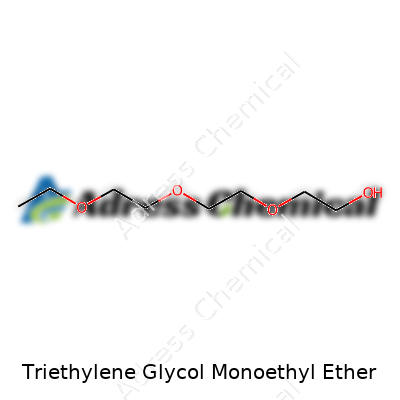

On the shelf, triethylene glycol monoethyl ether doesn’t grab attention like some household chemicals; clear, with a faint sweet odor, its appeal hides in its workhorse status. Its molecular backbone holds three ethylene glycol units with a single ethoxy tail, keeping it less flammable and less harsh than plenty of older alternatives. This kind of profile lets big-name chemical suppliers and niche distributors both list it as a multi-purpose product, not a one-trick pony limited to one niche. You spot it in a handful of cleaning solutions, paints, and coatings, but also as an intermediate in organic synthesis or as a solvent carrying active principles in specialty markers. Its suppliers, facing pressure to show safety and performance, rely on certifications and purity analyses to convince buyers it’s fit for their intended use.

This ether’s physical side tells a lot about why industries keep picking it. Its boiling point sits high enough to cut down on hazardous vapors—usually hovering around 256°C. This makes it far less risky than some lower-boiling solvents, especially when heat treatment or high-temperature processes come into play. The viscosity sits modestly, balancing between flow and cling; manufacturers and users don’t end up with a greasy mess or, on the other extreme, a runny puddle that evaporates at every turn. Solubility stands out, too. It dissolves polar and non-polar substances, letting paint makers, cleaners, and lab workers stretch it in many directions. Hydrogen bonding plays a quiet role here, giving the compound its unique mixability, but doesn’t cause it to solidify under ordinary storage. The chemical stability means it doesn’t degrade or react just because it sits in a tank for a few months, so wastage and spoilage remain minimal if you avoid contaminated containers or sunlight.

Manufacturers stamp out detailed technical sheets for triethylene glycol monoethyl ether, listing assay percent (above 98% for most industrial grades), water content, and heavy metals contamination thresholds. The clear labeling ensures buyers know what’s coming through their loading docks, especially given regulatory watchfulness over purity. Batch numbers, hazard statements, and precautionary symbols mark up every drum. Shipping containers, whether steel drums or HDPE carboys, list the CAS number (112-50-5) and the globally harmonized system (GHS) pictograms signaling irritancy or minor flammability. Big players in chemical logistics learned long ago that skipping these details risks regulatory fines and broken trust: a lesson hammered in over decades.

The preparation traces back to reaction between triethylene glycol and ethylating agents—most often ethyl chloride or ethyl bromide—using alkali or acidic catalysts to speed things up. Temperature control stands as a must, since side reactions make for a soup of glycols if left unchecked. Stirred-tank reactors dominate in large-scale plants. Every step needs someone who gets how exothermic shifts can creep in, risking safety and quality. Fractional distillation sorts out the monoethyl ether from byproducts, a demanding bit of work because separating ethers that cluster so close in boiling point means you can’t cut corners on equipment.

Triethylene glycol monoethyl ether plays nicely with most adduct reactions: acylations, oxidations, even mild reductions. Chemists pull it into esterification to build up surfactants, or break it down under harsh conditions to retrieve polyethylene glycol chains for lubricants. Under strong acid, the molecule can cleave, but it tends to hold up against bases unless specific reactive species join in. This stability wins it spots in formulations that get exposed to both acids and bases during their lifecycle, like detergents cleaned with both acidic and alkaline washes, or inks designed to resist environmental degradation.

This glycol ether answers to plenty of aliases. On industry spec sheets, you’ll find it listed as Ethoxytriglycol, Triethylene Glycol Ethyl Ether, TEGEE, or 2-(2-(2-Ethoxyethoxy)ethoxy)ethanol. European and American suppliers rarely agree on a single label for the chemical, but as long as you spot the CAS number, you know you’ve found the right compound. Some coatings manufacturers or pharma formulators coin branded names, but underneath it’s always the same set of atoms doing the heavy lifting. Confusion sometimes crops up due to the jungle of trade names, especially if you’re ordering for a mixed-use facility, so checking documentation has saved more than a few projects from backtracking after a bad shipment.

Lab safety officers circle the paragraph on triethylene glycol monoethyl ether’s low acute toxicity, but don’t shrug off the warnings. Prolonged skin contact still can cause irritation, and long-term inhalation isn’t free of risk. OSHA and EU REACH put it in a class that doesn’t demand panic but keeps tight on exposure thresholds, mandating gloves, goggles, splash-resistant aprons, and proper ventilation. Spills demand prompt cleaning—its formulation means it spreads fast and seeps into porous surfaces. Disposal hooks into the broader codes for glycol ethers: no kitchen-sink shortcuts. Industrial players team with waste handlers licensed for glycol recycling or incineration, and compliance audits clamp down hard where they smell corner-cutting.

Triethylene glycol monoethyl ether travels widely through industries. Die-makers rely on it for cleaning and degreasing metallic molds, since it strips residues without eating through specialized finishes. Paint shops blend it for use in waterborne coatings, exploiting the slow evaporation rate and mild odor to keep workplace air bearable and the paint film smooth. Markers and writing inks get their flow properties from its solvent characteristics, reducing bleeding and feathering on cheaper papers. Some pharmaceutical technicians use it as a carrier fluid for delicate botanical extracts, trusting the chemical’s approval status in regions less suspicious of glycol ethers. Electronics manufacturers value the ether’s low conductivity and lack of corrosivity, using it for server blade cleaning or LCD fabrication, where a failed clean can cost millions.

Academic labs and commercial R&D teams circle triethylene glycol monoethyl ether for new assignments. Every push for “greener” solvents sets off another burst of studies comparing it to bio-based alternatives. More than once, I’ve watched researchers scour published data, looking for tweaks that might nudge the molecule into a higher performance bracket or safer profile. Fluid dynamicists tinker with adding functional groups, searching for better viscosity or evaporative properties, while toxicologists spend years tracking long-term bioaccumulation. This ether also pops up in efforts to build surfactants with less aquatic toxicity. No matter how many lab benches get cluttered by new experiments, the drive to lower cost and lower risk keeps the molecule in play well beyond its original expectations.

Toxicology work on triethylene glycol monoethyl ether pulls in plenty of laboratory animals and human cell assays, thanks to the expanding focus on occupational health. Acute effects among exposed workers turn up seldom, but regulatory pressures haven’t eased up. Chronic exposure studies report minor liver enzyme elevation in high-dose settings, but nothing pointing to organ failure at real-world levels. Ecotoxicologists flag up fish and aquatic invertebrate sensitivity, yet wastewater filtering cuts off most routes to biosphere contamination. Health regulators track use closely, partly due to legacy issues around other glycol ethers harming fertility. Open data registries like ECHA show no major alarms, but the public’s appetite for transparency holds researchers to tighter and tighter reporting standards each year.

Triethylene glycol monoethyl ether doesn’t flash across headlines or celebrity ads, but it holds its own in industrial circles looking for reliability over hype. With pressure mounting around volatile organic compound (VOC) controls and greener chemistry, this ether still sounds appealing compared to the harsher products it often replaces. Emerging areas—battery tech, delicate microfabrication, greener inks—could stretch its use further. At the same time, ongoing tweaks in synthesis and purification could bring costs down and bump up sustainability. Suppliers who back up claims with lifecycle analysis, transparent documentation, and real-world exposure data stand a shot at keeping their share, while new regulations and the next wave of green tech may rewrite the landscape only time will tell.

Triethylene glycol monoethyl ether might sound like something straight out of a high school chemistry textbook, but most of us have felt its impact without ever knowing it. Factories, labs, and lots of old-school printers use this liquid because it gets along well with water and oils at the same time. That’s a rare skill in chemistry, and folks in manufacturing lean on it for that reason.

For example, many companies add it into industrial cleaners. It grabs oil and specks of dirt that won’t budge with water alone and keeps them dissolved until someone wipes them away. A lot of glass cleaners, degreasers, and floor polishes end up with at least a splash of it. The shiny finish at a school hallway or in a shopping center tells the story. In my younger days pushing a mop in a supermarket, some bottles had long scientific names. The floor dried streak-free only when the mix was right, and this one helped get the mix right.

Old-school offset printing and some types of inkjet cartridges feature triethylene glycol monoethyl ether in the recipe. It keeps pigments from clumping and lets them flow smoothly, making sure images and text come out crisp. Anyone who’s ever had a printer jam or blotchy print, especially on tricky glossy paper, probably dealt with ink that dried out or separated. By keeping things wet just enough but not too much, this liquid lets presses and home printers alike produce thousands of sharp pages without making a mess.

Paint needs to do two jobs: go on evenly, and dry without lumps or bubbles. This glycol helps keep paint stable in cans, so folks at the hardware store don’t open up ruined stock. It also gives painters time to fix mistakes before things set. Having dabbled with DIY furniture painting, I’ve noticed the difference between paints that dry too quick and those that spread out smooth – this is the sort of additive that makes detailed work easier for both pros and weekend warriors.

One challenge with triethylene glycol monoethyl ether comes from its ability to sneak through skin barriers and its low odor, making exposure hard to notice. Long hours in a print shop or cleaning too many floors in a row can add up. Nobody likes reading endless safety leaflets, but gloves and good ventilation make the difference. Agencies like OSHA warn about overexposure because some people get headaches, skin irritation, or worse when they let their guard down. At a paint shop I worked at years ago, keeping a window open and using nitrile gloves wasn’t just busywork; it kept me out of the doctor’s office.

It can be tempting for companies to chase the lowest cost and stick to tried-and-true chemicals. Still, pressure from environmental groups and a slow shift to more transparent safety labeling have pushed some manufacturers to look for alternatives. Water-based formulas sometimes cut down on the need for these solvents, and better workplace protections make life a little safer.

Many of us might not see the name triethylene glycol monoethyl ether when we pick up a cleaning product or a new can of paint. Its role behind the scenes proves that even unglamorous molecular workhorses shape how easy, safe, and clean our world can turn out—if we pay attention to how and why they’re used.

Triethylene glycol monoethyl ether, or TEGEE to keep things easy, doesn’t roll off the tongue, but it does show up in more industries than most people suspect. Folks working near solvents, cleaners, or paint removers run into this stuff even if the name hides on the label. I’ve seen it handled in labs where nobody bats an eye, and I’ve smelled its faint, sweet odor in workspaces where the ventilation isn’t quite up to snuff. It’s a colorless liquid, often tucked away in clear bottles with a slightly thick, syrupy feel. You splash some on your hands, you’ll notice oily slickness instead of harsh dryness—just a small hint of its heavy yet mild character.

TEGEE carries both an ether group and a bunch of ethylene glycol chains. This combo grants it a pretty impressive ability to dissolve other stuff, especially things like resins, oils, grease, and certain inks. For paint strippers or degreasers, you won’t get far without solvents that can juggle water and oil-based messes, and TEGEE steps in as one of those middle-ground cleaners.

With a boiling point hovering around 276°C, evaporation runs much slower than with lighter alcohols or ethers. I’ve watched puddles of this stuff linger on benchtops long after others dried up. At work, this feature actually helps guys who need a cleaning agent that won’t vanish before the job’s finished. It also means less vapor floating around, so there’s a bit less risk of inhaling too much—though, trust me, safety gear still stands as rule number one.

The viscosity lands somewhere between water and syrup, which means measuring and pouring stays clean—no sudden splashes or waste. Its vapor pressure ranks low, showing that you won’t usually see it racing out of its bottle except under serious heat. In industrial spots, this reduces headaches from constant air monitoring. Still, speaking from experience, gloves matter. Extended handling leads to mild irritation for some folks, though usually less than with harsher solvents.

There’s also the issue of combustibility. TEGEE won’t ignite easily at room temperature, but don’t get careless. Pouring gallons near sparks risks a nasty surprise because its flash point, sitting above 135°C, floats well above household table spirits but shouldn’t lull anyone into ignoring good storage rules. I’ve seen once-vigilant teams get complacent; a single misstep ends with emergency fans and heavy scolding. Proper containers—metal, sealed, and marked—go a long way in preventing disasters.

TEGEE doesn’t break down quickly when exposed to air or light. It stands tough in storage, barely reacting with plastics or glass, a blessing for warehouses working on tight budgets. The flip side emerges in wastewater; it doesn’t magically vanish. Discharge into the ground or water can stick around for a while. Studies point to slow decomposition unless industrial treatment jumps in early. I’ve talked with plant operators who say staying compliant with discharge laws means investing in better in-house treatment, not just trusting municipal systems to pick up the slack.

Handling chemicals with both cleaning brawn and resilience carries baggage. TEGEE’s benefits keep industry humming, but real accountability lies in safe usage and responsible disposal. Double-checking labels, donning gloves, and ventilating workspaces protect people. Yet that effort means nothing if liquid wastes pour down shop drains unchecked. I’ve learned from others’ mistakes as much as my own—labeling waste, logging shipments to disposal contractors, and listening to those who clean up accidents bring more peace of mind than just reading up on regulations. TEGEE’s strengths count for plenty, but how people work with it and where it ends up matter even more.

Triethylene glycol monoethyl ether shows up in a lot of places most folks don’t notice—industrial cleaners, paints, sometimes cosmetics. It’s colorless, has a mild smell, and mixes well with water. Anyone working in a factory or lab probably crosses paths with it somewhere down the line. People see words like “glycol ether” and assume trouble, and not for no reason—chemicals in this family don’t have spotless records.

Common sense tells us that frequent or heavy-duty exposure to industrial chemicals carries risks. This one’s no exception. Breathing in high amounts or rubbing it straight onto the skin every day can trigger headaches, dizziness, or irritation. It’s not a nerve agent or cyanide, but calling it harmless gives the wrong impression. The Material Safety Data Sheet warns about possible liver or kidney effects, and that didn’t come from creative writing. Factory safety teams ask workers to wear gloves and masks, wash up well after handling, and avoid sticking hands in their lunchbox with traces still on their skin.

Research offers up evidence. Animal tests with huge doses showed possible liver stress. There’s no flood of lawsuits or occupational cancer clusters tied to this chemical, but few folks want to join the first wave of a case study either. Regulatory agencies like OSHA flag it for “use care,” not for banning outright. The difference matters—using too much of anything, even table salt, ends up bad. Toxicity depends on dose and route. A splash on the skin clears up after a wash, but drinking a big cup would count as self-harm.

Thinking about risk always comes down to exposure. Janitors, factory technicians, or chemists working daily with open containers face more risk than a homeowner painting their fence. I spent a few months working near a plant, saw safety signs everywhere, and watched as supervisors checked protective gear fit—those extra steps pay off. One careless habit can turn a routine day into an ER visit, but following protocol shrinks risk to background noise.

Workers who deal with triethylene glycol monoethyl ether need clear rules and equipment that fits. Regular training helps people notice symptoms early, so health problems don’t sneak up. Swapping in less-toxic alternatives remains a good goal, though the right chemical isn’t always on the shelves yet. Management that listens when a worker mentions a weird rash or headache usually heads off bigger problems. Upgraded ventilation, gloves rated for chemical splash, and solid cleanup routines really matter—nobody wants to go home worried about what got into their system.

Ordinary folks at home don’t buy this chemical off the shelf much, but it can show up in paint or cleaning product labels in small amounts. Reading the label and keeping the garage aired out makes a difference. Kids and pets that can’t read warning labels count on adults to keep them safe, so locking up supplies pays dividends. I’ve made a habit of checking up on household products—there’s no hardship in using gloves or cracking a window open, habits that cost less than a doctor bill.

Triethylene glycol monoethyl ether doesn’t top the list for most dangerous chemicals in industry, but it still deserves respect. Regular folks rarely run into trouble, but workers surrounded by the stuff for hours each day need tighter controls and good habits. It’s easy to hope for quick fixes or magic bullet substitutes, but most progress relies on people bothering to follow the rules, spot issues soon, and keep up with updates from health agencies. That steady focus makes all the difference—not just for chemical safety, but for every workplace I’ve seen.

Anyone who’s worked around chemicals knows the mess that comes from ignoring storage advice. I’ve seen warping drums oozing odd liquids because the warehouse felt like a sauna, only for someone to shrug and say, “Never seen that happen before.” Triethylene Glycol Monoethyl Ether isn’t some casual cleaner to toss on the garage shelf. This liquid bends the rules as far as toxicity goes, has a knack for soaking into skin, and, if kicked over, can make a mess that lingers longer than most want to admit.

People store this chemical like it’s tap water until something warps, breaks, or leaks. The right answer looks simple: keep it somewhere cool, shaded, and well-ventilated. The flash point isn’t especially low, but it sure isn’t high enough to ignore heat or open flames nearby. Stack it in a hot metal shed out back and, eventually, even the best drum fails from pressure or corrosion.

A dedicated chemical storage room with proper airflow and clear warnings on the door saves future headaches. Always pick spots where the thermometer stops well below 30°C. Poor airflow lets vapors collect – not many workers want headaches, irritated eyes, or worse after clocking out. These fumes don’t belong in a worker’s lungs – all it takes is a single slip.

Sealed, tough, and labeled – that's how I always want containers that carry this stuff. Steel or multilayer plastic containers keep it from seeping out. I once saw clear plastic jugs turn cloudy and crack within months, so cheap containers cost more down the line. Labels need more than the product name; hazard pictograms, date received, and a contact for emergencies matter more than most realize. I haven’t forgotten the day two drums sat side by side – one misidentified – and nobody noticed until it was too late.

Soaking up a triethylene glycol monoethyl ether spill with rags leads straight to hazardous waste disposal problems if you’re not thinking it through. Absorbent pads and neutralizing agents pick up the slack when mistakes happen, but they need to be on hand and easy to reach. Spill-kits left buried at the back of the room won’t help. It’s easy to think, “That won’t happen to me,” but every facility I’ve worked in eventually sees that day.

Gloves, splash goggles, and a lab coat. That’s my uniform working near this chemical. Gloves suffer little holes or thin spots over time, so regular checks keep things safer. Not once have I heard a worker regret wearing a face shield after a close call. Shower and eyewash stations close by make accidents less painful and recovery less stressful.

It’s easy for managers to overlook training, sliding by on routine and luck. The difference comes when everyone knows where the data sheet lives, how to read a label, and what to do during an emergency. Real learning grows through regular walk-throughs, not just faded posters on the breakroom wall. Building serious habits around storage and handling keeps coworkers safe and prevents surprises nobody wants to clean up afterward.

Triethylene glycol monoethyl ether isn’t the stuff of science fiction horrors, but it doesn’t forgive lazy habits. The smartest facilities rethink storage layouts when delivery schedules change, swap out sketchy containers before leaks happen, and keep lines open with workers about near misses and actual spills. Investing in a safe workspace today always costs less than dealing with a big mistake tomorrow.

In the chemical world, there’s a habit of turning every substance into an endless jumble of names and numbers. Triethylene Glycol Monoethyl Ether isn’t a name you drop at a dinner table, but in labs, factories, and shipping containers, it stands out because of one ID: the CAS number 112-50-5. A string of numbers, sure, but a sign that what’s inside the drum matches what’s promised on the paperwork.

Years back, I spent a summer crawling through records for a manufacturing plant. We sorted every barrel by its CAS number. At first, the task felt robotic, but as workers started showing up with odd batches—labels torn, some in foreign languages—the importance of that number became clear. Folks weren’t just being nitpicky; misidentifying a substance meant shutting down machines or, sometimes, putting someone’s safety on the line. Nobody wanted that.

Triethylene Glycol Monoethyl Ether is used in processing oils, hydraulic fluids, or as a solvent that doesn’t grab headlines but keeps industries humming. Companies lean on that CAS number because common names change country to country, but that nine-digit sequence doesn’t lie. The numbers break language barriers. In technical documents, shipments, or chemical databases, 112-50-5 means one thing and one thing only.

Slip up on this and spray a cleaning crew with the wrong ether, or mix the wrong ingredient into a batch, and the tickets for damage control start piling up. My time at the plant taught me that fewer things are scarier than tracking down a bad batch without a traceable CAS number. No one wants to roll dice with hazardous chemicals.

Most folks don’t dwell on the little codes stamped on barrels, but chemical suppliers, shippers, and safety officers live by this system. Glancing at a bottle, the number 112-50-5 signals to workers, regulators, and chemists exactly what’s going on inside. That directness helps teams train the right way, signal the right hazards, and keep their stories straight for inspectors.

This detail keeps international trade honest, too. I’ve seen customs agents stop containers for less. If the CAS number doesn’t match the bill of lading, trucks sit idle, losing money by the hour. That string of numbers ends speculation and shortcuts; it saves businesses from grief and keeps local laws satisfied.

To keep confusion out of the picture, it helps to make CAS numbers as visible as possible—on paperwork, on drum labels, in training manuals. Cloud-based tracking and inventory apps help keep these numbers searchable on the fly. I’ve seen companies put up posters with the common CAS numbers in break rooms. These reminders, minor as they look, carry weight.

Manufacturers can go a step further. Standardizing labeling practices, never mixing batch numbers with chemical identifiers, and running spot checks make life easier down the road. Digital databases now cross-reference CAS numbers worldwide, but that’s only helpful if teams use them consistently. Always sticking with 112-50-5 for Triethylene Glycol Monoethyl Ether, no matter what catchy trade name comes along, simplifies life for everyone in the chain.

| Names | |

| Preferred IUPAC name | 2-[2-(2-ethoxyethoxy)ethoxy]ethanol |

| Other names |

Ethoxytriethylene glycol Triethylene glycol ethyl ether Tetrahydroxyethylether Ethoxy(triethylene glycol) Ethyl triethylene glycol ether 3,6,9-Trioxa-1-undecanol |

| Pronunciation | /traɪˌɛθ.ɪˈliːn ˌɡlaɪˌkɒl ˌmɒn.oʊˈɛθ.ɪr/ |

| Identifiers | |

| CAS Number | 112-50-5 |

| Beilstein Reference | 1721416 |

| ChEBI | CHEBI:51430 |

| ChEMBL | CHEMBL2276756 |

| ChemSpider | 18768 |

| DrugBank | DB14117 |

| ECHA InfoCard | 100.007.880 |

| EC Number | Triethylene Glycol Monoethyl Ether" EC Number: "203-919-7 |

| Gmelin Reference | 81611 |

| KEGG | C19602 |

| MeSH | D014265 |

| PubChem CID | 8128 |

| RTECS number | KL2975000 |

| UNII | 8U2UN309GL |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C8H18O4 |

| Molar mass | 162.20 g/mol |

| Appearance | Clear colorless liquid |

| Odor | Odorless |

| Density | 0.993 g/cm3 |

| Solubility in water | Miscible |

| log P | -0.38 |

| Vapor pressure | 0.03 mmHg (20 °C) |

| Acidity (pKa) | 14.7 |

| Basicity (pKb) | 4.40 |

| Magnetic susceptibility (χ) | -7.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.429 |

| Viscosity | 4.7 mPa·s (25 °C) |

| Dipole moment | 3.06 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 216.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -833.65 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4482.7 kJ/mol |

| Pharmacology | |

| ATC code | D07AB09 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P210, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 110°C (230°F) (closed cup) |

| Autoignition temperature | 225°C |

| Explosive limits | Explosive limits: "1.2% - 10.6% |

| Lethal dose or concentration | LD50 Oral Rat 7000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 6850 mg/kg |

| NIOSH | KL6025000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.5 ppm |

| Related compounds | |

| Related compounds |

Diethylene glycol monoethyl ether Tetraethylene glycol monoethyl ether Triethylene glycol Triethylene glycol dimethyl ether Triethylene glycol monomethyl ether |