Chemists in the early 20th century started searching for solvents that could work in polar and non-polar worlds and wouldn’t evaporate as quickly as diethyl ether. Triethylene glycol dimethyl ether, or triglyme, emerged from those labs, thanks to advances in the petrochemicals sector. As research in the ether category grew, this molecule caught the attention of industry because of its stability and the way it handled heat and solvents. Historical records show its gradual adoption in the electronics sector, especially as transistor and circuit design took off. Once the pharmaceutical and laboratory worlds caught on, triglyme became a go-to compound for tasks that required both resilience and performance in challenging conditions.

Triethylene glycol dimethyl ether stands out as a clear, colorless liquid that refuses to create fuss about smell—unless you take a deep breath over the bottle, in which case a faint ether scent greets you. Its appearance might not be flashy, but few molecules handle so many roles: high-boiling solvent, phase transfer medium, and lithium battery component. The balance between polar and non-polar character allows it to step into jobs that other solvents flinch at, ranging from synthesis to specialty cleaning. Flexibility like this doesn’t show up often in the chemical world, but triglyme juggles it with confidence.

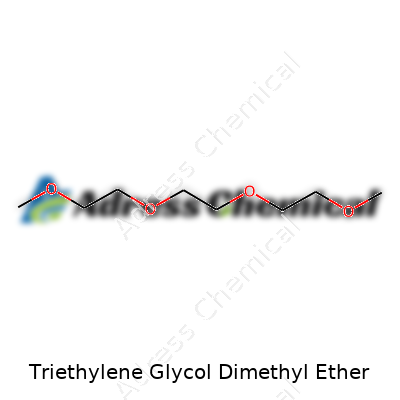

The molecular formula C8H18O4 tells part of the story, pointing to three ethylene oxide units capped with two methyl groups. Boiling at over 216°C, triglyme sticks around in reactions that would chase lighter ethers from the flask. Density falls just under 1 g/cm³, a match to many organic liquids, making it easy to handle with standard glassware. The low volatility keeps losses to a minimum, unlike older solvents that vanish after an hour on the bench. It refuses to mix with everything—water only accepts a bit, but organic solvents welcome it with open arms. This behavior shapes its role in electronics and synthetic chemistry, where water can spoil a reaction and triglyme stays in the mix. It's not prone to spontaneous peroxidation at room temperature like some smaller ethers, decreasing the risk when stored in typical chem labs.

In the plant or lab, triethylene glycol dimethyl ether usually arrives in steel drums or amber glass bottles. Labels carry its CAS number—112-49-2—alongside potency, showing percentage purity often topping 99%. Transport details and hazard symbols remain front and center, reflecting the industry’s concern with flammability and possible health hazards. Lot number and expiration date aren’t there for decoration—traceability ties into standards that demand quick action in case of spills or product recall. The labeling reflects trust in the supply chain, the reality that skilled workers want to know exactly what’s inside before pouring out another reagent.

Making triglyme involves a game of substitution and control. The process uses ethylene glycol as a base—the same stuff behind many winter windshields. It reacts with methylating agents under heat, often under pressure, swapping hydrogen atoms for methyl groups. The steps require refined technique, sealed reactors to block water, and careful monitoring to stop side products from taking over. Catalysts push the process along and distillation clears away byproducts. Authentic product comes not from shortcuts but from steady hands and years of trial and error. There’s nothing flashy about it, just stepwise engineering, careful temperature management, and patience.

Trglyme likes to blend in with many partners in the lab. It works as a ligand, grabbing onto metals and forming stable complexes crucial in catalysis. Some researchers push it further, swapping out end groups or stretching its backbone for niche roles in synthesis. These modifications change solubility, coordination, or thermal properties, opening new avenues for specific reactions. Despite its stability, triglyme can react with strong acids, breaking down into smaller chains, or serve as a phase carrier in multi-layered reactions. This chemical tractability sets it apart from less interesting solvents that demand caution but offer little chemistry in return.

Triethylene glycol dimethyl ether wears many hats in global trade. "Triglyme" sees the most use, but "dimethyltriglycol," "1,1'-[2,2,2-Trioxatrianometyl]dimethylether," and “Glyme 3” surface in catalogs and chemical datasheets. Some brands trademark a version, sometimes with a production batch code, to distinguish between sources. This can mislead newcomers, who wonder if they deal with new compounds, but the chemistry remains the same. Knowing which synonym pops up on a bottle saves headaches later, especially in international trade.

Triglyme keeps safety managers on their toes. It may not explode or catch fire easily, but the flammability risk lingers in high-heat settings. Extended exposure can cause tiredness or irritation—gloves and good ventilation aren’t negotiable. Regulations in Europe and the U.S. highlight its possible reproductive toxicity, which led to tighter labeling and stricter workplace limits. Plenty of companies switched to lined drums and vapor containment protocols to meet these expectations. In my experience, there’s no shortcut around safety; spilling triglyme in a closed room has reminded many researchers of the price of carelessness. Clear procedures, ongoing training, and transparent MSDS sheets form the backbone of responsible use.

Ask around research labs, and triglyme shows up as a solvent for high-stakes organic reactions requiring both solubility and thermal tolerance. It anchors the world of lithium-ion and lithium-metal batteries, acting as an electrolyte carrier to shuttle ions efficiently between electrodes. Processing electronics often depends on solvents that can handle hot, sensitive materials without dropping out at the wrong moment—here, triglyme delivers. Paints or specialty coatings rely on its slow evaporation and ability to keep pigments dispersed for longer working times. Sometimes, pharmaceutical scientists pick it apart for its ability to dissolve polar drugs in delivery experiments. I’ve even seen it supporting high-pressure catalytic tests, where cheaper solvents falter and reduce yields.

Research on triglyme keeps evolving, fueled by both demand for better battery performance and the need for green chemistry. The drive for non-volatile solvents in battery design pushes scientists to tune its molecular structure. Some teams swap methyl groups with longer chains to change boiling point or ionic conductivity. Companies in Europe and Asia pump resources into making derivatives that meet new environmental rules, reducing toxicity while maintaining the magic mix of stability and solvency. Graduate labs often experiment with triglyme in catalysis work, especially in bimetal complex synthesis or transition metal-catalyzed reactions. The blend of old-school chemistry and next-generation tweaks keeps this molecule in the R&D spotlight, especially in materials science and advanced manufacturing.

Science doesn’t sweep safety aside. Animal studies and real-world monitoring reveal that triglyme can disrupt reproductive systems with long-term exposure, prompting regulatory scrutiny. Chronic inhalation or skin contact correlates with mild to moderate organ effects in rodents, and this evidence shaped recent classification in Europe. Researchers look for metabolites in human cell cultures, trying to clarify whether breakdown products play a role in toxicity or if whole molecule absorption does the damage. This push for clarity explains new workplace standards—lower limits, safer storage, and improved spill response protocols.

The journey of triglyme heads into two directions—improving on its best qualities or replacing it with safer options. In my years of working with both small startups and large chemical firms, the discussion always turns towards “greener” replacements. Still, until a drop-in solvent with the same boiling point, polarity, and stability arrives, triglyme keeps its spot in specialty labs and manufacturing. Battery researchers, especially those working with solid-state or advanced lithium chemistries, look at tweaking its structure to maintain high performance without sacrificing worker safety. Companies keep scouting for catalysts or production paths that lower byproducts, cut waste, or recycle spent material. In the meantime, clear-headed regulation and adoption of best practices keep its risks in check, letting research push forward while minimizing harm to people and planet.

Triethylene glycol dimethyl ether, or triglyme if you want to keep things simple, rarely grabs headlines. You won’t find it trending on social media, but walk into a research lab or peek behind the scenes in many factories, and triglyme often makes an appearance. In my earliest days working as a lab assistant during college, I learned quickly that some of the most important chemistry workhorses keep a low profile. Triglyme is one of those — less glamorous than acetone or ethanol, but with a skill set that gets the job done.

Rechargeable batteries need stable, high-performing electrolytes. Many lithium-ion and lithium-sulfur battery researchers rely on triglyme as a solvent. Why? Its ability to dissolve lithium salts and handle a wide range of temperatures sets it apart from more basic options. The growing demand for electric vehicles and cleaner energy depends a lot on scientists finding reliable ways to store and move power. Triglyme’s high boiling point means battery cells aren’t at risk of shorting or burning up at the first sign of heat. Every time I drop my phone or bike light charges faster than I expect, I think about the hidden chemistries making that possible.

Organic synthesis isn’t just an academic exercise. The pharmaceutical world rushes forward on the back of reactions that need the right medium. I spent a summer job washing glassware in the development wing of a small pharma company. One day, I asked the principal scientist why triglyme came up so often in their reaction protocols. He pointed out that its low reactivity and excellent solvency for polar and non-polar reagents kept their sensitive processes running smoothly. The fewer side reactions, the better the yield and the purer the product. Drinks don’t taste right with dirty glasses, and drugs don’t work right with impure chemicals.

Factories and repair shops can’t function without solvents that pick up grease, oil, and other tough residues. Triglyme stands out among glycol ethers for its ability to break up messes. In many electronic component factories, including one I toured outside Chicago, they use it to flush circuit boards after soldering. The alternative—manual scrubbing—just slows everything down and risks damaging delicate parts. By keeping production lines moving and workers’ hands cleaner, triglyme proves that you don’t always need brute force to clean up jobs.

If you’ve ever worked with epoxy or polyester resins, you know mixing can get tricky. Making those mixes easy to handle and pour often relies on “co-solvents,” substances that help resins flow better at every stage. Triglyme is a regular fixture in formulating these products because it mixes well with both the resin and curing agents. I remember the subtle difference it made during a high school shop project—our resin batches set evenly, and we didn’t have to fight bubbles or streaks.

There’s a shadow that lingers, though. Triglyme’s persistence in water and the potential for health impacts mean that every industry using it should think twice. Some states in the US have added restrictions, pushing companies to hunt for substitutes. The answer isn’t as simple as switching to water or vinegar—the unique properties that make triglyme valuable aren’t easy to match. I’ve seen safer solvent blends in action, but almost always at a cost in productivity or consistency. The journey to greener chemistry isn’t a straight line. No matter what comes next, the lessons from working with compounds like triglyme remind us to stay humble and careful about what we let into our workplaces, and eventually, our environment.

Triethylene Glycol Dimethyl Ether goes by the formula C8H18O4, with a CAS number of 112-49-2. This isn’t just a dry technical detail for a regulatory filing. These identifiers shape everything from how companies order the chemical to what safety data hits the table in a research lab. The formula tells you exactly how many carbon, hydrogen, and oxygen atoms make up the molecule, and the CAS number is a universal reference in scientific databases. Whenever I’ve looked up a solvent for a project, the CAS number cuts out confusion, avoiding mix-ups that cost time or even safety.

Triethylene Glycol Dimethyl Ether isn’t a household name, but it pops up in more places than people assume. The chemical finds a home as a solvent in laboratories, battery electrolytes, and specialty lubricant blends. I’ve watched it support research in battery development—its low reactivity and ability to dissolve lithium salts help create more stable energy storage, which directly supports cleaner energy technology.

Its use as a specialty solvent comes with a mix of perks. The molecule holds up against a range of acids and bases, unlike many more volatile ethers. In the lab, this means less hassle over cross-reactions or chemical breakdowns. In industrial applications, easier process control could save money on downtime or wasted materials.

As soon as a chemical crosses a certain production threshold, people start asking tough questions: human health, environmental risk, clarity on sourcing. Anyone can see the importance of knowing what’s inside a bottle when handling compounds like Triethylene Glycol Dimethyl Ether. There’s no room for guesswork. Quality control managers want the CAS number; lab safety officers dig into the MSDS. The formula and official ID guard against mistakes—especially in environments where solvents can look and smell nearly identical.

During routine inspections in the chemical storage area, I’ve noticed how vital labeling and training become. Small errors—wrong tags, faded labels—can lead to dangerous accidents. Clear identification stands as the practical bedrock for chemical management systems. It’s not an abstract safeguard; it’s about keeping people and assets protected right now.

Every conversation in chemical manufacturing circles comes around to safety and environmental impact. Triethylene Glycol Dimethyl Ether checks some boxes, but attention still lands on storage, ventilation, and spill control. I’ve seen good results from plants that integrate secondary containment and regular leak checks. Offering regular, hands-on training means workers recognize the odor or symptoms of exposure before problems snowball.

The chemical industry keeps leaning toward transparency and greener chemistry. Switching to less toxic alternatives or cutting emissions from ether processing hasn’t always been easy, but companies know the pressure isn’t letting up. I once spoke with a facility manager who tracked solvent recycling output for their plant. Reusing recovered Triethylene Glycol Dimethyl Ether didn’t just reduce raw material costs—it also kept regulatory scrutiny in check and lessened environmental footprint.

Details like the chemical formula C8H18O4 and CAS number 112-49-2 do more than populate a database or a label. These details fuel real decisions in procurement, research, operations, and safety management. As chemicals like Triethylene Glycol Dimethyl Ether play silent but crucial roles in many sectors, putting these identifiers front and center leads to fewer errors, better safety, and smarter environmental practices. That’s a lesson worth remembering, both in the lab and in the plant.

Triethylene Glycol Dimethyl Ether—or simply, Triglyme—pops up in plenty of industrial labs and factories. Some might run into it if they tinker with electronics, work on battery research, or spend time cleaning precision instruments. This isn’t a chemical you see at the supermarket, but for those who cross paths with Triglyme, health and safety questions come up for a good reason.

Nobody likes the idea of breathing in toxic fumes or getting mysterious rashes from a job. With Triglyme, vapors can hang in the air. Even a quick smell brings on a kind of sharp, sweet odor. I’ve spent enough hours in chem labs to know what long exposure to chemical vapors can do; headaches, dry throat, and eye irritation are pretty common. Sometimes, folks exposed regularly start feeling tired or a bit off. Research has linked higher Triglyme exposures to kidney and liver effects in animal tests. Data around humans isn’t stacked as high as it is for some other solvents, but regulators haven’t turned a blind eye to the risk.

Back in the day, people didn't think twice before handling solvents with bare hands or skipping the fume hood. Now, more eyes are on Triglyme’s hazards. The European Union slapped it with a “Substance of Very High Concern” label, tied mostly to concerns about fertility and toxic effects. Overexposure becomes especially risky for people thinking about starting families. In my circle, stories circulate about coworkers who ignored safety data sheets, only to end up with health scares or repeated sick days. This isn’t just bureaucratic hand-wringing—these labels usually point to real risk from repeated handling or breathing in the stuff day after day.

Safety gear looks clunky, but that thick air mask or lab coat can keep a lot of trouble at bay. Ventilation makes an enormous difference. Even a small, good, fan drawing air away from the user will leave folks breathing easier and sleeping better knowing they did it right. If the aroma of Triglyme is in the air, it’s already moving into the lungs, so it makes sense to suit up before the smell hits. I’ve worked in places where management decided to swap out Triglyme once the risks became clear. Sure, it took a week or two to tweak processes, but the new chemicals caused less worry and didn’t trigger the same kinds of health complaints.

People sometimes resist swapping out chemicals like Triglyme because it works so well on delicate parts or specific reactions. That habit holds up only as long as health issues stay out of sight. But new alternatives keep showing up—options with less punch to the kidneys, less drama in the lab. Training workers, keeping gloves handy, and storing solvents in tight containers will always make a difference. None of this is rocket science—common sense and a bit of stubbornness about health can pull most people through without incident.

Taking short cuts on safety never feels worthwhile after it catches up. Those exposed to Triglyme are right to ask about health effects and press their employers for the right gear. Regulators watch these chemicals because chronic exposure rarely shows its hand immediately, and sharing information—between labs, across industries—pushes everyone in a better direction. As safer recipes keep landing on the workbench, the safest option often comes down to speaking up, staying sharp, and not brushing off that burning in the eyes or the thumping in the head.

Triethylene Glycol Dimethyl Ether, often labeled as TEGDME or triglyme, falls under a class of industrial solvents used in making batteries, specialty coatings, and pharmaceuticals. Reminders of past accidents in university labs and small manufacturing facilities have shown that ignoring the risks attached to this substance doesn’t end well for anyone involved. Inventory records, news stories, and chemical safety watchdogs keep repeating a simple message: accidents involving ether solvents like this one often start with someone underestimating them.

Every person who has worked with solvents knows the temptation to stash containers on the nearest open shelf or to crack a window rather than check the ventilation system. Triethylene Glycol Dimethyl Ether doesn’t have the wild volatility of diethyl ether, but it isn’t harmless. The stuff evaporates slowly, and those vapors catch fire more easily than many realize. Fumes linger unless a professional-grade exhaust system pulls them away. If you’ve worked in a workplace where air circulation was treated as an afterthought, you probably recall headaches, fatigue, or strange chemical odors. Those neglected symptoms add up over time.

Trying to get by with an ordinary cabinet or storing solvents in a break room closet spells trouble. Fires that start in crowded storerooms often spread before anyone reacts. Only metal safety cabinets, preferably grounded to avoid sparks, can slow the chain reaction if a leak or fire starts. I’ve seen labs try to save money by skipping approved cabinets, only to deal with insurance claims and ruined equipment later. Also, original containers with tight seals cut down on leaks; swapping to repurposed bottles often sets the stage for labeling mistakes, spills, and even more dangerous reactions.

Full-length gloves, splash-resistant goggles, and, at times, respirators, should never be an afterthought. Most exposure comes not from dramatic accidents but from little drips when pouring, or from contaminated gloves that touch unprotected skin. Safety data sheets (SDS) always call for these steps, but some skip over them to catch up on deadlines. It’s worth remembering that minor contact leads to skin irritation and inhalation over long shifts eventually harms the lungs.

Reading labels and clicking through boring training videos won’t put anyone on the edge of their seat, but experience shows that regular refreshers cut down on accidents. At several companies I’ve worked with, hands-on spill drills and clear signage did more to protect people than written protocols alone. If new hires can answer questions about emergency eyewash stations or fire suppression gear, everyone has a safer day ahead.

Pouring leftover ether down the drain sounds convenient, but this practice pollutes water supplies and violates more regulations than most folks realize. Coded waste containers, regular pickups by certified chemical disposal services, and cooperation with local hazardous waste programs all play a part. My experience with city inspectors reminded me just how expensive improper disposal can become, with fines stacking up fast.

Attitudes shape outcomes. Those who treat TEGDME with the same seriousness as gasoline or other flammable chemicals rarely regret a little extra caution. Changing habits doesn’t come overnight, but swapping shortcuts for clear procedures, investing in simple protective gear, and refusing to cut corners costs less than medical bills, equipment replacements, and fire damage in the long haul.

Triethylene glycol dimethyl ether, sometimes called triglyme, lands itself in labs and plants because of its unique physical and chemical mix. The molecule brings together long ether chains, ending in two methyl groups. This design makes it far from an ordinary solvent you’d find under your sink. You’re looking at a clear, colorless liquid, and it doesn’t shout about its chemical power—no strong odor, no immediate warning signs from the bottle.

It’s not every liquid that boils at around 216°C and refuses to freeze solid until temperatures drop down below -30°C. That kind of thermal range is a lifesaver for chemists who hate surprises during reactions or distillations. Viscosity sits somewhere on the lighter side, so pouring, mixing, and transferring don’t slow down a production line or bench work. No need for exotic equipment—standard glassware handles it well, though gloves are a smart move.

The low vapor pressure means this stuff doesn’t just vanish into the air at room temperature. That’s a personal favorite—less cleanup, less exposure, less headache for anyone concerned about air quality in close-quartered workspaces. It mixes into water in only a limited way, but it loves to mingle with alcohols and other organics, making it a regular fit for extraction and solvent blends in pharmaceuticals and electronics manufacturing.

Those ether links carry real weight in chemistry. Triethylene glycol dimethyl ether shrugs off acids and bases—within reason. Anyone working through complex syntheses values a solvent that doesn’t turn around and bite them midway. It doesn’t oxidize easily, so you won’t find your flask building odd residues after storage or mild heating. Higher polarity compared to traditional ethers also means better action when dissolving salts, a helpful trait for battery techs and those dabbling in electrolytes for research or commercial applications.

The thing nobody enjoys: flammability. Triglyme lights up at about 111°C. Precautions stay important, but it won’t blow up in your face at room temperature, which brings peace of mind during long, unpredictable shifts. In the right (or wrong) setting, with strong oxidizers in play, you’d still be wise to keep safety at the front of your mind.

Industries choose their chemicals based on more than spreadsheets. A solvent like triethylene glycol dimethyl ether cuts down on lost product and strengthens reliability for folks making pharmaceuticals, fine chemicals, and polymer products. Its thermal stability reduces risk—no sudden reactions or boiling over. In personal experience, using triglyme on bench-scale reactions gave a level of control I couldn’t find with cheaper, more volatile ethers. For battery researchers, this solvent pushes capabilities in lithium-ion work, holding electrolytes stable for extended runs. The lack of rapid evaporation means costly materials don’t end up in the ventilation system.

No chemical is tame if treated carelessly. Though triglyme behaves better than plenty of flammable liquids, anyone working with large volumes needs good ventilation, suitable PPE, and practical spill plans. Chronic exposure has prompted concern among health agencies, and some regional controls reflect that. Reading the SDS and checking for any new regulations keeps accidents out of the news. Better engineering controls and substitution with less hazardous ethers could lower potential risks over time—but in the meantime, knowledge and good habits carry the day.

| Names | |

| Preferred IUPAC name | 1,2-Bis(2-methoxyethoxy)ethane |

| Other names |

1,2-Bis(2-methoxyethoxy)ethane Triglyme |

| Pronunciation | /traɪˌɛθ.ɪˈliːn ɡlaɪˈkɒl daɪˈmɛθ.ɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 112-49-2 |

| Beilstein Reference | 1858736 |

| ChEBI | CHEBI:83738 |

| ChEMBL | CHEMBL165360 |

| ChemSpider | 6071 |

| DrugBank | DB14049 |

| ECHA InfoCard | 47eaeda9-6ca2-4b2d-b8ad-7486dfb9fcdc |

| EC Number | 203-977-3 |

| Gmelin Reference | 108473 |

| KEGG | C19697 |

| MeSH | D014260 |

| PubChem CID | 8215 |

| RTECS number | KL5950000 |

| UNII | N3I1LV5F1G |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | DTXSID1026977 |

| Properties | |

| Chemical formula | C8H18O4 |

| Molar mass | 222.28 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 0.954 g/mL at 25 °C(lit.) |

| Solubility in water | miscible |

| log P | 0.23 |

| Vapor pressure | 0.02 mmHg (20°C) |

| Acidity (pKa) | 47.1 |

| Basicity (pKb) | The basicity (pKb) of Triethylene Glycol Dimethyl Ether is "–1.0". |

| Magnetic susceptibility (χ) | -71.5e-6 cm³/mol |

| Refractive index (nD) | 1.424 |

| Viscosity | 1.1 mPa·s (20 °C) |

| Dipole moment | 1.51 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 217.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -576.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3940.7 kJ/mol |

| Pharmacology | |

| ATC code | D08AX02 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. H319: Causes serious eye irritation. H335: May cause respiratory irritation. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P280, P303+P361+P353, P304+P340, P312, P337+P313, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 113 °C |

| Autoignition temperature | 215 °C |

| Explosive limits | Explosive limits: 1.3–19% (in air) |

| Lethal dose or concentration | LD50 Oral Rat 16,100 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 6500 mg/kg |

| NIOSH | UI2275000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Diethylene glycol dimethyl ether Tetraethylene glycol dimethyl ether Ethylene glycol dimethyl ether |