Tetraethylene glycol dimethyl ether didn’t spring up overnight, and someone who has watched chemistry progress over time can see how demand for new solvents shaped its story. Chemists in the mid-20th century went after molecules able to dissolve salts and organometallics better than the stuff their predecessors used. More flexible polyethers came into play after crown ethers arrived, but the regular, linear glymes like tetraethylene glycol dimethyl ether were easier to make, less bulky, and behaved reliably. As labs explored new synthesis routes and batteries asked for better electrolytes, this ether gained traction, especially due to its relatively straightforward production from cheap, available feedstocks like ethylene oxide.

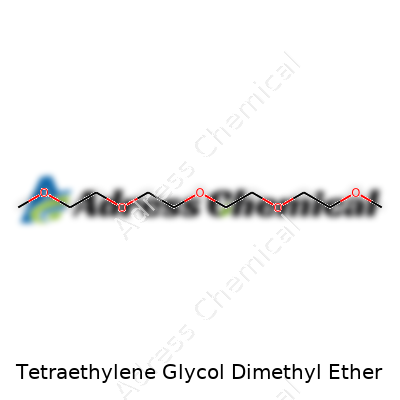

You’ll find tetraethylene glycol dimethyl ether listed as a clear, colorless, somewhat viscous liquid that barely budges from neutrality in pH. It smells faintly sweet, a bit like many glycols and ethers do—if you’ve ever cracked open a leftover bottle of brake fluid or a jug of unfinished antifreeze, you might notice something similar wafting up. This ether doesn’t just linger in a corner; it serves as a solvent, an electrolyte component, sometimes a reaction medium in labs trying to push the limits. Folks have called it by different names: tetraglyme, TEGDME, and 2,5,8,11,14-pentaoxapentadecane, among others. Each name reflects its structure—a chain of oxygens stitched together by ethylene bridges ending in methyls.

This stuff doesn’t boil easily, even well past the point where you’d start sweating in a lab. Its boiling point reaches around 275°C, and it doesn’t freeze solid until the temperature plummets to -30°C or lower. It mixes smoothly with water and many organic solvents, giving it flexibility across different tasks. Chemically, the long chain shields it from fast degradation. It resists attack from most mild acids and bases, but strong oxidizers chew it up quickly. I’ve seen samples break down slowly if left uncapped for weeks in a humid store room, especially if exposed to sunlight—not the fastest decomposer, but not invincible either.

Catalogs tend to list this ether as >99% pure for industrial or research use, flashing hazard symbols for flammability and possible skin and eye irritancy. Labels often show CAS number 143-24-8 and advise strict storage—sealed containers, away from ignition sources, no direct sunlight. In my own practice, suppliers rarely miss a beat, but I always double-check for trace impurities, particularly peroxides, which can pop up in aged stock and cause equipment issues or even accidents. These specs matter to anyone running sensitive reactions or producing materials for batteries where every impurity can knock performance off the mark.

Making tetraethylene glycol dimethyl ether looks simple on paper—mix ethylene oxide with methanol in the presence of a base and keep repeating until you build out the chain to the right length. In practice, though, nailing the chain length and scrubbing out short or long byproducts isn’t trivial. Producers run columns and distill off undesired fractions, being careful to remove water and unreacted methanol that would otherwise drag down the yield or complicate downstream applications. Watching a production batch unfold, you see how attention to temperature control, catalyst choice, and purification steps becomes the backbone of reliable output.

Most people turn to this compound for its stability, but it does have a few reactive sites—especially under harsh conditions. Exposing it to strong acids can snip up the ether linkages, leaving shorter fragments. Treating it with sodium or potassium can yank off the hydrogens on those methyl ends, making it possible to craft more specialized ligands or tweak its properties for niche battery uses. Folks working in organic synthesis sometimes push it into more obscure modifications, using it as a flexible backbone to build even longer or more complex glymes, though cost and practicality keep it from running wild in labs.

Depending on the catalog or country, you’ll spot this molecule under: tetraglyme, TEGDME, dimethyl tetraethylene glycol ether, and a batch of IUPAC-style names that show up more in patents. Walgreens and Wholesalers don’t really stack it on shelves, but research warehouses and specialty chemical suppliers keep clear labels to avoid confusion with similar glymes like diglyme or triglyme—mistakes here can send a whole experiment sideways or spoil a product line.

Working with tetraethylene glycol dimethyl ether has given most chemists a lesson in steady, careful habit. The liquid itself isn’t wildly dangerous, but improper handling or long-term exposure isn’t wise. Vapors build up flammable atmospheres if ventilation fails. There’s a real need for goggles and gloves, since splashes sting eyes and skin. Longer stints in closed spaces without extraction fans always make me anxious. Safety data sheets emphasize health risks, but many folks forget the peroxide issue: storing samples for months, especially in half-full bottles exposed to air, can let peroxides form quietly. That’s why labs, including ones I’ve worked in, test older stock with iodine paper and keep antioxidants on hand to neutralize anything suspicious.

Electrolyte manufacturers have fallen for tetraglyme thanks to its high boiling point and ability to dissolve lithium salts without breaking down. Its use stretches from lithium-ion batteries in the test stages to some batches of sodium battery prototypes. Beyond that, it acts as a solvent for complexation reactions—helping some transition metal catalysts get up to speed—or as a carrier for heat transfer fluids where old-school glycols don’t meet the mark. In the pharmaceuticals and electronics sectors, researchers sometimes turn to it for specialty syntheses where regular ethers fall short. From my perspective, the biggest push now comes from battery labs, searching for stability and compatibility with new electrode materials—tetraglyme sometimes makes or breaks the pursuit of safer, longer-lasting cells.

Chemists in R&D haven’t left tetraethylene glycol dimethyl ether alone. The push for safe, non-flammable electrolytes in next-generation batteries places it under regular scrutiny. Labs tinker with subtle tweaks—adding stabilizers, mixing with ionic liquids, or blending with related glymes to stretch battery cycle life. Beyond batteries, catalysis researchers look for ways to anchor metal complexes to its oxygen-rich backbone, hoping for new, more active catalyst systems. In green chemistry, a few groups have tried to design recyclable reaction media or greener extraction systems—it’s no stranger to innovation, though adoption faces roadblocks from cost, toxicity concerns, and regulatory scrutiny.

Toxicological profiles for this ether remain less notorious than those for some older solvents, but what’s in the books demands respect. Acute exposures cause irritation, possibly headache, and more worrisome effects after inhalation—chronic handling without proper controls could raise risks to kidneys and liver, at least according to early animal studies. Some researchers in the 1980s and 1990s flagged developmental issues in rodents, yet regulatory reviews call the evidence mixed for people, especially given the low volatility and relatively modest industrial usage. From firsthand habit, I’ve learned that constant vigilance—fresh gloves, working in fume hoods, careful waste treatment—pays off in maintaining a safe workspace while larger regulatory bodies scrape together conclusive human data.

Momentum for safer, more efficient batteries gives tetraglyme both opportunity and scrutiny. Researchers keep pushing the limits, blending it with fluorinated solvents or other glymes to hit the sweet spot of conductivity, thermal stability, and low volatility. Industry buzz hints at opportunities in solid-state battery systems, though nothing is set in stone. Pharmaceutical and fine chemical fields push for solvents with lower toxicity and higher recyclability, potentially squeezing out older glymes if greener options or robust recycling emerges. I’ve watched colleagues chase alternatives in search of safety, but for now, tetraglyme holds on—supported by a combination of reliable performance and incremental improvements. The challenge remains: balance its unique properties with health concerns and environmental standards, finding new chemistry that genuinely outpaces what’s already here.

Some chemicals get all the attention, but that doesn’t mean there aren’t under-the-radar players doing essential jobs. Tetraethylene Glycol Dimethyl Ether—better known in labs as TEGDME or tetraglyme—is one of those. On its own, it’s a clear, less volatile liquid with a mild, almost sweet scent. It’s not likely to end up in a home garage, but anyone dealing with batteries, pharmaceuticals, or high-tech labs has probably heard the name. My first brush with TEGDME came during a stint at a battery research lab—long days spent chasing better energy storage and learning that some materials quietly carry a ton of responsibility.

It’s hard to talk about advances in batteries without mentioning the solvents inside them. TEGDME steps up as an electrolyte solvent in rechargeable lithium batteries, especially for lithium-air batteries. There’s no electric car on the road or phone in your pocket without workhorse chemicals like this somewhere in the background. Its low volatility and stability at high voltages let engineers squeeze more performance out of a battery. Safety matters, too—lower flammability means fewer risks during charging or transport. I remember how frustrating it felt working with earlier solvents that would evaporate or break down too soon. TEGDME helped clear some of those roadblocks.

Chemists keep their toolboxes full of solvents that don’t just dissolve things, but set the stage for tricky reactions. TEGDME is one of those favorites, capable of dissolving both polar and non-polar compounds. When the goal is making a pharmaceutical in a handful of careful steps, skipping a solvent like this isn’t an option. Peptide coupling, oxidation, even some specialized polymerizations—all feel smoother with a solvent that stays put and doesn’t react with every stray molecule. I’ve watched grad students shake their heads over ruined batches from using the wrong solvent, so the reliability of TEGDME stands out.

There’s an almost invisible world of industrial fluids—keeping equipment from overheating, transferring heat without breaking down. TEGDME often rides this wave, especially in closed-loop systems or where resistance to decomposition matters. It handles heat better than water or light oils, with a boiling point north of most alternatives, so you end up with fewer shutdowns on the factory floor. In high-tech labs, running sensitive analytical equipment often means plumbing cooling lines with materials like TEGDME that won’t gunk up or degrade under pressure.

Anyone who’s ever tried scrubbing a sticky, stubborn residue off glassware knows why specialty solvents exist. TEGDME steps into this role if you’re cleaning precision parts, electronics, or lab equipment that can’t handle water. Electronics repair shops, for example, lean on solvents like TEGDME because water promotes rust and short-circuits. I’ve seen this solvent lift stubborn grease off circuit boards that looked unsalvageable.

No chemical gets a free pass. Disposal counts—TEGDME doesn’t break down as quickly as we’d like. Some places keep a nervous eye on how much ends up in wastewater. Regulations should keep pace with growing demand, and designers should push for recycling in closed systems where solvents like TEGDME keep recirculating rather than ending up in the environment. Research is pushing for greener alternatives, but we’re not there yet. Until then, careful handling and smart system design must stay front and center.

Anyone who works in labs, chemical plants, or industries where solvents play a part will recognize the significance of knowing the specifics about chemicals they handle. Tetraethylene Glycol Dimethyl Ether, known in the trade as TEGDME or tetraglyme, carries the chemical formula C10H22O5. Its CAS number is 143-24-8. These simple facts might look like checkboxes for documentation, but they matter more than most people realize.

Every day, folks open drums or bottles labeled with a formula or a CAS number and trust that what’s inside matches that description. For TEGDME, this is especially important. I’ve spent time working in a lab where the smallest mix-up could knock an entire experiment out of commission, cost thousands, or even put safety at risk.

Having an exact chemical identity—both formula and CAS number—cuts out confusion. Tetraethylene Glycol Dimethyl Ether has a very different set of properties compared to its cousins, like diethylene glycol dimethyl ether. These numbers act as a universal key, a common language that prevents costly misunderstandings, not just between colleagues, but across borders as chemicals get shipped around the world.

The use of TEGDME stretches beyond just being “another solvent.” It’s a favorite in battery research, electrolytes for lithium and sodium batteries, heat transfer fluids, and even specialties in pharmaceuticals. What caught my attention years ago was its role in making non-aqueous electrolyte solutions more stable and less volatile—a godsend in early-stage battery trials. Folks banking on this chemical for consistent performance don’t have patience for impurity or swaps with similar-sounding chemicals.

For chemists, mixing the wrong compound isn’t something out of a comedy skit. Consequences range from botched reactions all the way up to dangerous releases of unwanted byproducts. Using TEGDME and not a lookalike safeguards results and safety, relying on more than just a product name scribbled on a bottle.

Far too often, I’ve seen cases where someone relies on an old data sheet or a verbal description. Mismatches between what is ordered and what is delivered slow down work. With TEGDME, older synonyms or generic naming can mean a shipment doesn’t bring what the team needs. That’s where standardized identifiers like the CAS number ride to the rescue, providing absolute clarity regardless of language or region.

Improving this situation doesn’t require new laws. Companies can make sure all training covers the difference between formula naming, CAS numbers, and trade names. Printing the right facts on every label—from the big drums down to the smallest vials—solves most confusion. Electronic inventory systems help by tying these identifiers together, so nobody is left staring at a string of numbers without backup.

As someone who’s seen the consequences of ambiguous chemical sourcing, I know firsthand that the specifics matter. Tetraethylene Glycol Dimethyl Ether’s formula, C10H22O5, and its CAS number, 143-24-8, save more headaches than they cause. With so much riding on a clear identity, there’s plenty of payoff for getting it right every time, for every shipment, and every experiment.

A lot of problems start when chemicals sit in the wrong spot, or folks ignore warnings on the label. Over the years, I’ve watched small mistakes turn into headaches—a half-used bottle left uncapped, a drum set too close to a heat source, or labels that just wore off. Without paying close attention, the risk isn’t just property damage, but sometimes health or even life.

Certain chemicals react fast to air, light, or a temperature shift. I’ve learned that accident stories usually start with shortcuts. Say, someone chucks a solvent under the sink or in a stuffy shed. Humidity creeps in, or a leaky pipe drips, and suddenly there’s a mess. Some harsh cleaners and acids eat through containers if left unchecked. Others simply turn hazardous fumes loose when jostled around.

Reading the label seems simple, but it’s often skipped. I’ve seen dozens of folks in a rush, not bothering with gloves or eye protection. Sometimes labels fade or peel, and nobody bothers writing the chemical name back on. In less than a year, someone might grab the wrong bottle and pour it into a drain or onto the wrong surface, forgetting what’s inside. Using a permanent marker or printouts solves more problems than you’d think.

None of the fancy storage cabinets in the world can make up for sloppy habits. Everything starts with the basics: keep chemicals dry, away from heat, and out of reach if kids or pets are around. Flammable stuff belongs away from sunlight and open flames. Strong acids and bases need their own corners—never share a shelf unless you want an exothermic show. I got burned once by mixing two things in the same bag. Minor accident, big lesson.

In my experience, a well-aired room matters. Closed-off storage or poorly ventilated workspaces build up hidden fumes. Over time, headaches and breathing issues surprise people who thought “that’s just the smell.” A small fan and open windows help, along with frequent checks for leaks. Wipe up spills immediately. Disposable towels and a separate trash bin for contaminated materials work better than pretending the spill never happened.

Buying in bulk sounds smart until storage space runs short. At the hardware store, I used to splurge on discounted gallons, only to find containers outlasting their usefulness. Stockpiling, especially in unlabelled containers, invites confusion. Keeping only what’s needed, along with regular inventory checks, cuts down waste and chance of an accident.

Plenty of accidents happen because everyone assumes someone else took care of safety. Short, honest talks about what to do with spills, where to store bottles, and how to read warning symbols help everyone look out for each other. A laminated sheet of instructions on the wall gives everyone a quick refresher after months of routine. I’ve seen more confidence with simple reminders than all-day seminars.

In the busy rush of projects or chores, it’s easy to believe “nothing will happen.” But one splash in the eye or an unexpected reaction can hijack a whole day—or more. Respect for what’s in each container, using safety gear, and never mixing unknown leftovers goes further than any slogan. This is the sort of lesson that sticks, usually because I, or a friend, learned it the hard way. Store smart, handle with focus, and most troubles stay far from your door.

A name like Tetraethylene Glycol Dimethyl Ether (often called TEGDME or tetraglyme) might sound like something you’d find in a high-tech chemistry lab – and that's not too far from the truth. It's a clear liquid, with a faint smell, used mostly as a solvent in batteries, electronics, and some chemical processes. Folks who work in labs or advanced manufacturing will probably cross paths with it more than the average person. But does this stuff bring danger along with its tongue-twister name?

Experience working around industrial chemicals teaches a few things. Even if something goes largely unnoticed outside of specialist circles, it can carry risks. Digging into the data, you’ll notice that TEGDME isn't considered wildly more hazardous than similar solvents, but it doesn’t win any safety awards either.

The irritation factor pops up first—this liquid can bother your skin and eyes, and breathing in the vapors for extended periods leaves your lungs unhappy. Chronic exposure isn’t good; reports mention headaches, dizziness, and even liver or kidney trouble over the long haul. Some animal studies have raised questions about effects on fertility and fetal development, which is never something to brush off. Agencies like the European Chemicals Agency have stuck precautionary labels on tetraglyme for reproductive toxicity based on such findings. That doesn’t mean a splash on your hand equals disaster, but it does mean giving this stuff healthier respect in the workplace.

Having worked with a variety of cleaners, degreasers, and solvents, it's easy to get casual—for better or worse. Plenty of classic solvents, like toluene or formaldehyde, come with much more dramatic health warnings. But just because TEGDME hasn't landed in headlines for hospitalizing people doesn’t mean it gets a blank check. Safety data sheets often feature phrases like “use with adequate ventilation” and “avoid prolonged or repeated contact.” A chemical doesn’t need to explode to cause lasting effects—it just needs enough unprotected exposure, often over months or years.

The rules that keep people out of trouble are mostly old-school. Use gloves. Stick with goggles if there’s any splash risk. Adequate ventilation can mean the difference between an annoying smell and a trip to an occupational doctor. It’s easy to roll your eyes at wearing a mask or chemical-resistant apron, but these habits pay off in the long term. If a spill happens, clean-up becomes a chore, not a crisis, if you’re ready for it. Working in a lab setting, seeing a co-worker get burned—or end up with a rash that takes weeks to clear—drills in the lesson that complacency isn’t worth it. Safety isn’t just about avoiding accidents. It’s about protecting yourself from what you can’t see or feel right away.

In the chemical world, rules tighten up as we learn more. Tetraethylene Glycol Dimethyl Ether hasn’t landed on the most wanted list, but its reproductive hazard label suggests regulators have their eyes on it. Tighter restrictions could come down the pipe as research fills gaps. Companies can get ahead of the game by phasing in better control systems, training people more clearly, and exploring safer alternatives where possible.

The people who spend their careers around these solvents know that any chemical with a record of irritation and reproductive risk deserves real caution. It’s not about fearmongering—it’s about understanding the risks, respecting the material, and passing that sense of responsibility to every new hand in the shop. Nobody gets nostalgic for chemical burns or headaches, and taking TEGDME seriously keeps those stories out of the break room.

Whenever somebody asks about the typical purity of a product, they’re getting at a question most users rarely voice: what exactly am I working with? Years spent in labs and warehouses have made one thing clear to me. Purity matters, sometimes more than even the branding or price tag. Whether we’re talking chemicals, food ingredients, or raw materials for manufacturing, purity reflects quality, safety, and, sometimes, regulatory compliance.

Take industrial chemicals like sodium chloride, for example. High-purity grades, say above 99.5%, target the pharmaceutical industry. On the other hand, lower grades find their home in de-icing or agriculture. I once saw a shipment labeled as “pure,” meant for a food plant, get turned back because its certificate showed 97%. Two small percentage points, yet the products meant for your kitchen or hospital just can’t risk impurity-related side effects. Impurities bring more than unwanted taste or appearance; they introduce safety hazards or weird reactions downstream.

Electronics manufacturing tells the same tale—semiconductor-grade silicon climbs above 99.9999% purity, which certainly doesn’t leave a lot of room for error. Even a deep fryer in a donut shop needs oil with strict purity so the result tastes right and poses no health risk. If you’ve ever watched how even household bleach lists active ingredient percentages, you get a sense of just how much granular detail goes into these grades. It’s not driven by regulations alone, though those set the bar. Long-standing experience, demanding customers, and even brand reputation hang in the balance every time purity isn’t just on paper, but embodied in the product itself.

Now turn to packaging. Purity would stay theoretical if packaging didn’t keep it safe from the factory to the end application. I’ve watched manufacturers struggle at this step more than once. Cardboard boxes crumble in humid storerooms, metal drums that rust, plastic bags prone to tears—all of these threaten what’s inside. Bulk commodities like food grains arrive in heavy-duty 25 kilogram sacks, often made of woven polypropylene. Each sack bears a clear batch number, manufacturing date, and labeling that’s hard to tamper with.

Industrial powders come vacuum-sealed in multilayer bags if the air or moisture threatens purity. One chemical plant I worked with only used double-bagged, heat-sealed containers, and if you broke the outer barrier, a tamper-evident seal waited inside. This was partly about keeping stuff in, but mostly about keeping everything else out. Some products, such as pharmaceutical ingredients, show up in high-density polyethylene drums with coded seals, barcodes, and traceability information. For delays at customs or extended shipping, that backup information solved problems faster than any email chain could.

I’ve also seen food additives transported in foil-and-paper laminate pouches, a far cry from old-school burlap sacks. Temperature control gets more attention too—some stuff comes nested with silica gel, others in insulated boxes that keep temperatures steady for days. For products like honey or syrups, glass and thick plastic bottles do the double duty of preserving quality and showing off color and clarity.

There’s still plenty of work to do. Trust gaps widen every time a shipment looks re-packed or the purity number gets fudged. Buyers need consistent lab certificates with third-party backing, not photocopies whipped up at shipping time. Packaging could use more biodegradable, robust options; personally, I’d like to see less reliance on plastics for single-use transit. Building honest supply chains and maintaining the advertised purity in real conditions—hot, cold, humid, crowded—calls for a mix of diligence and smarter design, not just more regulation or inspection.

Whether your perspective comes from a factory floor, small business, or kitchen counter, those basic details—purity and packaging—shape what you get, how safe it is, and whether anyone wants to buy it again.

| Names | |

| Preferred IUPAC name | 1-methoxy-2-[2-[2-(2-methoxyethoxy)ethoxy]ethoxy]ethane |

| Other names |

TEGDME Tetraethylene Glycol Dimethyl Ether Dimethyl Tetraethylene Glycol 1,2-Bis(2-methoxyethoxy)ethane Dimethyl Tetraethyleneglycol Glyme, tetraethylene |

| Pronunciation | /ˌtɛtrəˈɛθɪliːn ɡlaɪˌkɒl daɪˈmɛθɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 143-24-8 |

| Beilstein Reference | 107878 |

| ChEBI | CHEBI:35962 |

| ChEMBL | CHEMBL49870 |

| ChemSpider | 16755 |

| DrugBank | DB14057 |

| ECHA InfoCard | 20-211-975-5 |

| EC Number | 206-223-5 |

| Gmelin Reference | 72943 |

| KEGG | C19616 |

| MeSH | D013742 |

| PubChem CID | 8229 |

| RTECS number | KW2975000 |

| UNII | UZI8P56KMA |

| UN number | UN3272 |

| CompTox Dashboard (EPA) | DTXSID9020840 |

| Properties | |

| Chemical formula | C10H22O5 |

| Molar mass | 222.31 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 0.978 g/cm3 |

| Solubility in water | Miscible |

| log P | -0.02 |

| Vapor pressure | < 0.01 mmHg (20°C) |

| Acidity (pKa) | 13.1 |

| Basicity (pKb) | 2.90 |

| Magnetic susceptibility (χ) | -58.5×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.414 |

| Viscosity | 3.8 mPa·s (25 °C) |

| Dipole moment | 2.48 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 368.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -607.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4335.7 kJ/mol |

| Pharmacology | |

| ATC code | D06AX02 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H319, H332 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | Flash point: 115°C |

| Autoignition temperature | 215 °C |

| Explosive limits | Explosive limits: 0.7% - 4.6% |

| Lethal dose or concentration | LD50 (oral, rat): 7,050 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 6,570 mg/kg |

| NIOSH | KWG795 |

| REL (Recommended) | 1 ppm (6 mg/m³) |

| IDLH (Immediate danger) | 300 ppm |

| Related compounds | |

| Related compounds |

Dimethoxyethane Diethylene glycol dimethyl ether Triethylene glycol dimethyl ether Polyethylene glycol Tetraethylene glycol |