Walking back through the chemical corridors of the late 20th century, it’s easy to spot propylene glycol propyl ether emerging just as industries pressed for smarter, safer, and more nimble solvents. Regulations grew teeth; folks who worked in paint booths or printing plants needed alternatives to harsher glycol ethers that left them with headaches or worse. Watching the market bend, chemical makers leaned into compounds like this one, giving buyers more choices—especially people aiming to avoid highly regulated ingredients without wrecking performance. The growth picked up pace as safety data became clearer and new regulations in the US and Europe left many manufacturers scrambling for substances that both soothed the health concerns and got the industrial job done.

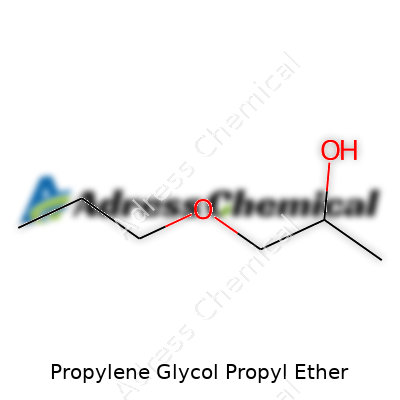

Propylene glycol propyl ether sits in warehouses labeled as PnP or PPGPE; to chemists, it’s 1-propoxy-2-propanol. The liquid barely knows what color even is, running nearly clear in every drum I’ve seen, and the smell brings to mind freshly opened markers from art class more than anything menacing. It slips right into jobs as a solvent—easing ingredients into solutions for coatings, inks, cleaners, and some adhesives. The chemical bridges that sweet spot between power and subtlety, cutting through greasy residues but playing well enough with water to make for simple clean-ups when the work ends.

Most people handling this stuff notice straight off that it feels less slick and sticky compared to older-generation glycol ethers. It carries a lower vapor pressure, meaning fewer fumes sneak up on you in a cramped workshop. Its boiling point hovers around 150°C, which gives it time to work without flashing off too fast or sitting heavy on surfaces for hours. The molecular shape keeps it miscible in both water and organic solvents, making it a flexible workhorse in blended systems. Folks who work with large vats appreciate that it doesn’t take much to fully wash out tanks and lines, saving headaches at the end of a shift.

Labels on drums or smaller containers usually lay out the CAS number (1569-01-3), along with purity—industrial grades almost always hit above 99%. You’ll see flags about flammability and recommended exposure limits. In practice, companies printing hazard labels rarely skimp, given the international trade. Companies shipping into Europe tag it per REACH standards, while in the U.S., OSHA's Hazard Communication Standard steers label language. Having seen both, I trust anyone loading barrels from reputable suppliers understands that the paperwork means more than just compliance; it’s about keeping real workspaces safe for actual people.

Making propylene glycol propyl ether starts with a reaction between propylene oxide and propanol. The method often relies on base catalysis—strong alkalis steer the oxirane ring to open and hook onto the alcohol. Plant operators pay attention to reaction temps and times because the end product’s purity and yield depend on getting the ratios just right. Any slip, and impurities bump up—the kind that can gunk up coatings or trigger unwanted reactions in downstream processes. A chemistry professor once described industry synthesis as “cooking for scientists”—never get distracted, and always know what’s in the pot.

On the lab bench, propylene glycol propyl ether plays supportive roles with a willingness to react under the right nudge. It handles oxidation without going wild, and alkali exposure brings structural tweaks that researchers and manufacturers both pursue—sometimes for specialty surfactants or as intermediates in more complex syntheses. In blends, it acts as a compatibilizer, and I’ve watched seasoned chemists tinker with its ratios in cleaning products till formulas cleaned glass without leaving streaks. Not flashy, but quietly vital.

Depending on the label, you might spot it as PnP, PPGPE, or 1-propoxy-2-propanol. Some companies sell it as Arcosolv PnP or Dowanol PnP. If you’re reading a European data sheet, they’ll stick close to IUPAC naming, but industrial catalogs in the US seem to enjoy the shorter forms. Synonyms aren’t just a paperwork hassle—they matter for suppliers, buyers, and anyone searching databases for safety profiles or import codes.

People working with this compound need to keep eyes on air ventilation; the sweet smell doesn’t signal complete safety, and regular exposure checks on factory floors protect both lungs and livelihoods. Even with lower toxicity compared to some of its chemical cousins, gloves and goggles always stay close at hand. Spills feel less urgent than acids or flammable solvents, but prompt cleanup is just common sense. The American Conference of Governmental Industrial Hygienists sets threshold limits, and workplace compliance audits don’t hesitate to flag misuse. In the long run, simple vigilance avoids problems—engineers I’ve met emphasize that an ounce of prevention beats any excuse written after the fact.

Take a look inside factories blending cleaning products or paints and you’ll see tanks of propylene glycol propyl ether moving through lines. Window and floor cleaners, paints in new homes, pressure-sensitive adhesive labels—all get a smooth finish with a little help from this solvent. Printers appreciate the clean evaporation; workers in auto shops rely on degreasing power. Environmental managers often lean toward it because local water boards give them less grief compared to alternatives better known for stubborn residues. The cleaner air and easier storage mean less tension with regulatory bodies, making it a friend to operations managers under pressure to keep both regulators and frontline teams content.

Chemical research labs worldwide treat propylene glycol propyl ether as a reliable control in comparative studies. Teams in Asia and Europe tinker with analogs to chase even lower toxicity or greater biodegradability. In my own talks with R&D teams, I’ve heard how pressure mounts to find drop-in replacements after every round of regulatory updates; propylene glycol propyl ether often stands as a benchmark solvent, helping filter less promising contenders before bigger investments. Universities dig into its use for new waterborne polyurethane dispersions, hunting for ways to stabilize tricky mixtures without loading up on volatile organic compounds.

Most papers point to relatively low acute toxicity, which eases nerves around large-scale use, but the chemical isn’t harmless. Inhalation at high doses irritates airways, and direct skin contact after long shifts can dry or redden exposed hands. Long-term studies focus on reproductive toxicity or subtle metabolic effects—none conclusively flagging severe dangers, but enough to keep health and safety committees attentive. Some European dossiers keep the ingredient under regular review, and industrial hygienists stay updated on emerging data, especially after incidents in sister industries spill lessons into broader chemical safety protocols.

Across labs and factory floors, conversations keep circling back to sustainability mandates and worker well-being. Propylene glycol propyl ether likely keeps its seat at the table for years ahead, thanks to decent performance and a middle ground on lots of risk metrics. Still, I hear suppliers anticipating tighter standards, so they invest in green chemistry labs and alternative production methods to preempt trouble. If biodegradable solvents reach cost parity and scale, propylene glycol propyl ether could slip from its spot, but not without a robust replacement. Looking at market data, investment in this compound’s usability within lower-impact coatings and advanced cleaning agents looks steady. For companies tired of leap-frogging every five years to chase compliance, finding a reliable baseline keeps operations smoother and workers safer, balancing both innovation and caution in real-world settings.

Walk down the cleaning aisle and glance at the labels on heavy-duty degreasers or glass sprays. Propylene glycol propyl ether often pops up, though most folks barely notice. From my time working with commercial cleaning services, this chemical makes tough grime back off without turning hands raw or noses twitchy, unlike old-school solvents. It softens up grease and dirt quickly, which means less elbow grease for cleaners and better results for everyone trying to keep surfaces spotless.

Back in college, I worked in a print shop, and the boss always wanted inks that dried evenly but didn’t gunk up the presses. Propylene glycol propyl ether flows into all sorts of paints, coatings, and inks for exactly that reason. It keeps things smooth, helps pigments spread evenly, and won’t leave behind a sticky mess. It also helps speed up drying, so factory lines and painters don’t spend half their day waiting for things to cure. With this solvent, maintenance guys can lay down a coat of paint before lunch, then let people back in the room by dinner. That cuts downtime and saves money, which matters more than most folks realize.

Ever bought a bottle of household cleaner promising clear streak-free glass? Chances are, you’ve wiped down the kitchen table with something that leans on propylene glycol propyl ether for its punch. It mixes well with water and oil-based ingredients alike, unlocking formulas that cut through fingerprints one minute and dried-on sauce the next. So, one ingredient solves problems across brands and surfaces, sparing shoppers the headache of juggling a dozen bottles under the sink.

People sometimes worry about chemical names on the back of cleaning bottles. In my experience, safety depends on more than just the name. Propylene glycol propyl ether breaks down pretty fast in the environment and hasn’t drawn the big safety red flags some older solvents did. Still, gloves and ventilation matter, just like with any chemical. A good rule: don’t treat it as harmless, but don’t panic either. I’ve seen workplaces use it safely by following label directions and giving workers the right gear. That kind of common sense makes the whole difference.

Cleaning, coating, painting—they’re not leaving our lives anytime soon, so solutions like propylene glycol propyl ether stay in demand. That said, a few companies try to cut down on petrochemical-based ingredients or search for plant-based swaps. It won’t happen overnight, since performance counts too. Until a stronger, safer, and more sustainable substitute shows up, this chemical keeps doing the heavy lifting, mostly unnoticed—except maybe by those of us who see what actually goes into making things clean or keeping colors even.

Propylene glycol propyl ether, often shortened to PnP, shows up in a bunch of things around the home and workplace. It acts as a solvent, cutting through grease and grime in cleaners and paint. You find it in floor polishes, and it even pops up in inks. I’ve always wondered what gets my kitchen cleaner to cut through the sticky stuff so easily—turns out, this chemical plays a big part in that magic.

Safety gets complicated fast when you start looking at industrial chemicals with strange names. Government agencies like the EPA and the European Chemicals Agency have run studies on propylene glycol propyl ether. What they show matches up with what I’ve experienced as someone who’s handled plenty of cleaning sprays—using this chemical in small amounts and with a bit of sense rarely causes any harm. Skin might get a little irritated if you don’t wash it off. Breathing it in straight from the bottle will make your nose tingle and your head ache. Most products only use a small percentage, way under levels that might do damage.

California lists it as a substance with “mild concern,” which seems to hold up based on experience. The trouble comes when a job requires working with drums of the stuff every single day, especially without gloves or good ventilation. You can get coughing, dizziness, or redness on your hands. A small spill in the garage won’t send you to the ER, but you don’t want to bathe in the stuff either.

Lots of formulas rely on PnP because water alone rarely gets the job done. People want their homes spotless, and artists crave smooth paint. The trade-off comes down to convenience versus possible risk. Kids and pets crawl and play wherever we clean. I see the issue right at home. We want gleaming floors, but breathing the fumes or letting little ones lick surfaces after cleaning doesn't sound smart. Responsible companies make products in concentrations that rarely cause problems from ordinary use.

Over the years, I’ve found two things that work: good habits and clear information. Open a few windows, grab gloves, and you’ll almost never get a rash or headaches. Storing bottles out of reach keeps children safe. Labels matter—if a product clearly warns you about fumes or recommends ventilation, trust that advice. Many manufacturers have also started putting less harsh stuff in their sprays and polishes, and some products wear third-party “Safer Choice” badges. This makes decisions easier, especially if someone at home has allergies or asthma.

For workplaces, the solution never surprises me: training and proper gear saves trouble down the line. Strong rules don’t just protect employees—they keep costs down by avoiding medical bills.

Natural cleaners keep growing in popularity, and some of these choices perform well enough for light jobs. Vinegar, baking soda, and even old-fashioned elbow grease handle much more than people realize. Paint shops and big cleaning companies need more powerful solutions, but most of us can switch out at least one or two bottles each year for something milder.

Propylene glycol propyl ether isn’t public enemy number one. With clear info, a bit of care, and smarter choices, most people can enjoy sparkling homes and sharp paint without a second thought.

Propylene glycol propyl ether pops up in more places than most of us realize. It plays a key role in products as basic as household cleaners to the paints that coat walls, and even in some inks. I once tried to clean off a stubborn marker stain using a generic cleaner; later, reading the label, I spotted this chemical in the ingredients list. That got me curious about why it shows up in so many formulas we trust at home and at work.

One thing that stands out about this solvent: it plays nice with both water and a fair selection of oils. Paint manufacturers, for instance, look for ingredients that help distribute pigments evenly—no streaks, no sticky patches. With propylene glycol propyl ether added to the mix, paints and inks achieve better flow. It helps cut through grease and grime too, which explains why cleaning products lean on its powers. It doesn’t leave a smeary mess behind, either. From my own experience with DIY painting projects, getting a streak-free finish is far from guaranteed unless the paint has just the right solvent blend.

Anyone who’s ever opened a can of paint gets hit with the smell pretty quick. Some solvents are harsh and linger for hours. Propylene glycol propyl ether doesn’t have that biting, nose-burning odor. Factories like working with it for the same reason people use it at home: the workplace stays more comfortable, and the products become easier to tolerate. If you have to spend all day in an enclosed space using solvent-heavy products, this trait matters.

Solvents don’t all dry at the same speed. Some evaporate fast, others hang around too long. Propylene glycol propyl ether dries slower than some “hotter” solvents like ethanol or acetone, but much quicker than the slowest in the bunch. This can be a blessing for those wanting a smooth coat of paint—no rush, but also no sticky residue hanging around for hours. During a sticky summer, I learned the hard way that finish and drying windows aren’t just a chemist’s problem; they affect how well my refinished furniture turns out.

Safety matters, period. Most health agencies see this substance as low in toxicity under typical use, which is more than can be said for some of the nastier steam-cleaning chemicals or certain paint removers. This doesn’t give anyone a free pass to ignore good ventilation or avoid gloves, though. I’ve seen people develop redness just from repeated contact—even mild chemicals can add up if someone handles them every day.

With all eyes on safer alternatives and less pollution, manufacturers look for solutions that do the job without piling on bigger problems. Propylene glycol propyl ether breaks down in the environment, which keeps it out of the long-lasting pollutant group. Still, that doesn’t mean dumping large amounts down the drain makes sense. Cities facing wastewater challenges have started raising concerns about solvents washing out of shops and factories—larger producers have to answer to tougher standards, but home users play a part too.

There’s always room for safer, greener chemistry. Chemists keep exploring plant-based options as substitutes, but right now, propylene glycol propyl ether walks that fine line between safety, cost, and performance. I’ve seen plenty of new “natural” products enter the shelves—sometimes they work beautifully, sometimes not so much. There’s value in understanding what each ingredient does, and propylene glycol propyl ether stands as an example of this ongoing compromise between what works and what works best for everyone, including the planet.

You can’t just ignore the storage of any chemical, especially Propylene Glycol Propyl Ether. I remember working a summer job in an auto body shop, where we kept solvents tucked away so far from the paint booth you’d be forgiven for thinking they were rare treasures. Nobody at the shop had a chemistry degree, but we all learned early how one careless move with the wrong fluid could mess up both health and hardware.

Propylene Glycol Propyl Ether catches flammable liquids on its label. Leaving it anywhere but in tight, well-marked containers is like inviting trouble. A simple, sturdy metal canister with a tightly fitting cap goes a long way. Set it in cabinets designed for flammable liquids, preferably with self-closing doors. Concrete floors, not wood. I used to see people stash chemicals on shelves over their heads or by the coffee pot—probably for convenience. Years of watching accidents pile up have convinced me shortcuts don’t save time, they make more work.

Some chemicals don’t like sunlight or heat, and Propylene Glycol Propyl Ether fits that group. Direct sun turns safe storage into a risk. All it takes is one heat wave in July, and you’re halfway to disaster. Never once saw my old boss skimp on cooling for the storage shed. You don’t want to set up shop near a heating vent, either. Cool, dry, and shaded places win every time.

Humidity sneaks up and causes rust, knocking years off steel containers. I used to check the bottoms for corrosion, and if one felt damp or sticky, it went straight out. Water and chemicals love mischief if left alone together. Find a place where the air moves, not where fumes build up. Propylene Glycol Propyl Ether gives off vapors. Stale air lets them pile up, making headaches and fire risk both more likely.

Labels sometimes peel, or somebody forgets to mark what’s in a jug. There’s no excuse for that. We used big, bold letters—even on backup containers—because if someone snags the wrong can in a rush, they pay the price. A simple checklist does more than fancy tech: label everything, lock it up, make a note, and double-check before heading out. Stored chemicals don’t stay safe just because you put them away once; it’s keeping an eye on them every week that beats complacency.

It never hurts to keep a fire extinguisher close. Training the new folks keeps everybody sharper because one person not knowing emergency steps is one too many. Remembering the right solvent for a rag spill, closing the door on the cabinet after a late shift, turning the bottle instead of yanking it up by the cap—these are things built from habit, not rules taped on a wall.

Checklist, container, location. These three things shape safer workplaces and protect everyone from mistakes. Routine walks through the storage area low-key catch leaks or loose lids, and stopping to deal with them means nobody gets hurt. Regulations aren’t just for show. They stick around because one small mistake turns into tomorrow's headline, easy. Propylene Glycol Propyl Ether isn’t the scariest chemical out there, but if you give it respect, you keep trouble off your doorstep.

Propylene Glycol Propyl Ether (PGPE) might sound like a mouthful, but it pops up in a lot of places: paints, cleaners, inks, and some coatings. Many folks, including myself, end up using these products at home or work without realizing what’s actually in them. Once empty bottles get tossed or something spills in the garage, the question crops up—what happens to it in the environment? Will nature take care of it, or are we setting up for a bigger mess down the road?

I remember working on a renovation crew that used floor cleaners and solvents. Most days ended with buckets of rinse water swirling down a drain. Nobody really thought about the ingredients back then. Years later, I wanted to know: were those chemicals sticking around in the local water or soil?

With PGPE, research says microbes can tackle it pretty well. Studies by the EPA and the European Chemicals Agency show PGPE breaks down under controlled sewage treatment and natural soil conditions. The process tends to finish in just a few weeks, especially when there are plenty of bacteria around. This looks better than stubborn stuff like PFAS, which hangs around for ages, refusing to break down.

Even if PGPE doesn’t build up in groundwater or soil, that’s not a free pass to use it carelessly. If a huge spill landed in a quiet pond or a river running slow, it could take longer to vanish. Plus, other ingredients in cleaner formulas might create bigger problems. So the answer is not black and white.

It’s easy for companies to advertise a “biodegradable” label and leave it at that, as if nature handles everything smoothly. In the real world, it’s a little messier. Sometimes things break down only under perfect lab conditions, which don’t always show up in a backyard or a city stream.

The bottom line: PGPE is more environmentally friendly than solvents that linger for years. Still, relying too much on its ability to disappear can give people a false sense of safety. Responsible disposal—using up what’s in a container, avoiding dumping leftover cleaner into a gutter—makes a big difference, no matter how biodegradable a chemical is on paper.

Testing alternative products at home, I’ve run into newer water-based cleaners that skip PGPE altogether. Not every job needs a strong solvent. By picking these, not only do I avoid questionable runoff, but there’s less hassle about air quality and empty bottles.

Manufacturers deserve some credit: they’ve cut back on the worst offenders and looked for formulas that break down faster. Still, pressure comes from regular people asking for ingredient lists and greener options. Laws about labeling and rigorous spill clean-ups can also keep companies honest. At the end of the day, trust has to be earned by showing real-world results, not just lab data.

Biodegradability matters, but it doesn’t solve everything. My own habits—using less, buying smarter, and not pouring leftovers where they don’t belong—help limit the problem at the source. If suppliers answer the call for transparency and safer choices, and if I keep up my end of the deal as a consumer, there’s a decent shot at shrinking our environmental footprint. With chemicals like PGPE, everyone’s decision—no matter how small—can nudge things the right way.

| Names | |

| Preferred IUPAC name | 1-propoxypropan-2-ol |

| Other names |

1-Propoxy-2-propanol Propylene glycol n-propyl ether PnP PGPE Propyl proxitol |

| Pronunciation | /prəˈpiːliːn ˈɡlaɪˌkɒl ˈprɒpɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 1569-01-3 |

| Beilstein Reference | 0898733 |

| ChEBI | CHEBI:82723 |

| ChEMBL | CHEMBL165194 |

| ChemSpider | 55312 |

| DrugBank | DB14155 |

| ECHA InfoCard | 100.031.032 |

| EC Number | 603-177-00-8 |

| Gmelin Reference | 104932 |

| KEGG | C09963 |

| MeSH | D017423 |

| PubChem CID | 8057 |

| RTECS number | UZ8750000 |

| UNII | 6DC9Q167V3 |

| UN number | UN3272 |

| Properties | |

| Chemical formula | C6H14O2 |

| Molar mass | 118.18 g/mol |

| Appearance | Colorless liquid |

| Odor | Mild ether-like odor |

| Density | 0.87 g/cm³ |

| Solubility in water | Miscible |

| log P | 0.36 |

| Vapor pressure | 0.27 mmHg @ 20°C |

| Acidity (pKa) | 14.8 |

| Basicity (pKb) | 7.9 |

| Magnetic susceptibility (χ) | –9.63×10⁻⁶ |

| Refractive index (nD) | 1.404 |

| Viscosity | 2.5 mPa·s (at 25 °C) |

| Dipole moment | 3.52 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 404.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -481.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4007.7 kJ/mol |

| Pharmacology | |

| ATC code | D01AE24 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378, P403+P235 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 66°C |

| Autoignition temperature | 230 °C (446 °F) |

| Explosive limits | 1.1% - 13.7% |

| Lethal dose or concentration | LD50 oral rat 3,317 mg/kg |

| LD50 (median dose) | 1,870 mg/kg (rat) |

| NIOSH | WI9250000 |

| PEL (Permissible) | PEL = Not established |

| REL (Recommended) | 10 ppm |

| Related compounds | |

| Related compounds |

Propylene glycol butyl ether Ethylene glycol propyl ether Dipropylene glycol methyl ether Propylene glycol methyl ether Propylene glycol 1-Propoxy-2-propanol Propylene glycol n-propyl ether acetate |