Back in the 1960s and 70s, global industrialization saw interest surge in glycol ethers for their promising solvency and versatility. Paint manufacturers and specialty chemical innovators hunted for safer, more adaptable alternatives to toxic solvents like aromatic hydrocarbons. Scientists pushed boundaries in ether chemistry, and along the way, Propylene Glycol Phenyl Ether (PGPE) made its mark. As industry looked for compounds with improved worker safety and lower volatility, PGPE became an understated but critical choice for labs and manufacturing floors, particularly because chemists could tinker with structure to fine-tune performance. Today, whenever someone peels a stubborn label with an industrial cleaner, or mixes up a specialty ink, PGPE might be at work, thanks to decades of gradual adoption, regulatory approval, and technical validation.

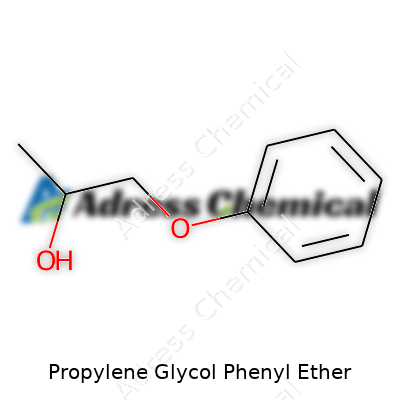

Propylene Glycol Phenyl Ether falls squarely into the family of glycol ethers—chemicals built to deliver strong solvency for tough resins, oils, pigments, and polymers. With a molecular formula of C9H12O2 and CAS Number 770-35-4, it’s found in colorless, slightly viscous liquid form. Chemists appreciate its low odor profile, which matters in formulas for consumer products. Its ability to dissolve hydrophobic and hydrophilic ingredients places it in formulations ranging from cleaning agents and textiles to coatings, inks, and adhesives. The phenyl group on the glycol backbone gives PGPE a performance boost in selectivity and compatibility compared to its cousins like dipropylene glycol methyl ether.

PGPE offers a boiling point of about 243°C and a flash point near 116°C (closed cup), so it stands up to higher processing temperatures than many conventional solvents. This kind of thermal stability reduces hazards during storage and transport. Its moderate vapor pressure keeps evaporative loss in check, which translates to less workplace inhalation exposure for folks working with the compound. Viscosity measured around 20 centipoise at 25°C, and density sits at roughly 1.06 g/cm³. Solubility features that strike a balance: PGPE doesn’t mix well with water, but chemists blend it easily into common organic solvents and many industrial fluids. The aromatic ring on the ether stretches solvency without cranking up toxicity or irritancy too much—something rare among chemical cousins.

Manufacturers deliver PGPE at purities over 99%. Each batch gets scrutinized for color, moisture content, acidity, and contaminant traces. Safety Data Sheets describe hazard class, handling, and storage notes, thanks to regulations like OSHA Hazard Communication or Europe’s REACH. You’ll see GHS pictograms flagging potential skin or eye irritancy, even if cases stay rare on the shop floor. Product labeling includes standardized names, UN transport codes, and supplier traceability markers. No one wants to mix up solvents in a high-stakes plant, so these specs help operators cut through confusion during delivery, inventory, or emergency response.

PGPE production takes a basic nucleophilic substitution route. Chemists react propylene oxide with phenol in the presence of an alkaline catalyst, controlling temperature and pressure to push the reaction toward the ether linkage. Industrial syntheses use reactors with tight temperature monitoring, reducing batch-to-batch variation and unwanted tars. Unreacted feedstock and byproducts wash away during purification. Some plants filter with activated carbon to clean up trace impurities, and vacuum distillation rounds out the process. The science looks straightforward, but process control keeps the doors open and regulators happy.

PGPE doesn’t spend its life alone. Chemical engineers seize its ether bond and phenyl group as jumping-off points. The molecule stands up to routine transesterification, halogenation, or ring-substitution reactions. PGPE can serve as a growth base for blocked isocyanates or advanced polymers. In waterborne coatings or high-performance adhesives, modified PGPE derivatives help fine-tune drying times, adhesion, and material compatibility. These modifications let chemists trade off between reactivity, volatility, and solubility or chase new regulatory benchmarks as safety standards shift. Newer green chemistry pushes labs to tweak the molecule, lowering VOC content or swapping in biobased feedstocks.

Ask a dozen chemists, and you might hear “Phenoxypropanol,” “PPH,” or even “1-Phenoxy-2-Propanol.” Some product sheets use “Propylene glycol monophenyl ether.” International trade lists slip in “Dowanol PPH,” or “Arcosolv PPH.” Suppliers in Europe or North America may assign proprietary codes, but CAS 770-35-4 and UN1219 help cut through naming confusion. Anyone sourcing this compound for a new project or trying to match customer spec sheets ends up cross-referencing these labels.

While PGPE lands low compared to legacy solvents in most risk profiles, standard safety practices matter. Contact with eyes or skin triggers brief irritation in some users—chemists and operators rely on gloves, goggles, and good ventilation when handling drums or mixing formulations. Inhalation can cause headaches or discomfort at high vapor concentrations, though the risk stands mild compared to many glycol ethers. Regulatory agencies like OSHA, the European Chemicals Agency, and China’s GB standards all require labeling, risk evaluation, and exposure control protocols, which shape standard operating procedures. Facility response plans stay in place for leaks or accidental exposure; no matter the chemical, risk management stays at center stage.

Industries lean on PGPE’s solvency and moderate evaporation rate. Paints and coatings companies value the way it reduces viscosity, levels out brush marks, and keeps pigment in suspension. Printers and ink makers praise its ability to keep pigment particles finely dispersed, boosting print clarity and drying predictably. PGPE features in cleaning agents for electronics and precision metalwork because it cuts stubborn greases and flux, staying gentle on sensitive surfaces. Textile mills and adhesive makers take advantage of its solvency and compatibility. Its low odor has earned it a spot in personal-care product labs, where blenders must tiptoe around skin sensitivity. Over the years, I’ve seen formulation scientists swap out older, hazardous glycol ethers for PGPE and use its flexible profile to meet tough health benchmarks.

Laboratories keep searching for better, safer solvents as regulatory screws tighten globally. PGPE stands out in ongoing R&D for multifunctional formulations. Researchers have tested it in green chemistry projects, tweaking molecule structure to match low VOC rules. Polymer scientists experiment with PGPE derivatives in waterborne resins and adhesives, searching for performance that beats older products built with more hazardous glycol ethers. Test data points to biocompatibility improvements, and toxicologists watch for subtle, chronic health differences in exposure—no stone goes unturned as chemists race to balance efficiency, compliance, and safety benchmarks in a changing market.

Much of the corporate lab work and academia digs into PGPE’s toxicology profile. Rats and mice dosed at high levels showed low acute toxicity; systemic effects rarely pop up below industry-use concentrations. Repeated skin contact, especially under occlusive conditions, may cause mild dermatitis but no persistent or organ-targeting toxicity, based on published data from regulatory bodies. Long-term inhalation studies flagged minor respiratory issues at exposures much higher than normal workplace levels. Environmental assessments have so far ranked PGPE low for bioaccumulation and aquatic toxicity, but new regulations push for expanded eco-toxicology studies. As someone who spent time with occupational health teams in the chemical industry, I keep returning to the old lesson: continuous monitoring beats chasing after surprises once they show up in a workforce.

Property needs and regulatory demands never stop moving. Paint and coating giants keep hunting for solvents that clear strict VOC caps without giving up on flow or finish. PGPE stands a strong chance for wider use in eco-labeled cleaning agents and lower-risk personal care packaging. The shift toward renewable feedstocks might lead to biobased PGPE analogs, blending performance with sustainability. Chemical startups and research parks see a future in specialty derivatives—tailored for target adhesives, advanced engineered plastics, and electronics. The tide in chemical regulations always changes, so those in the field anticipate not just tougher limits, but fresh innovation as labs push PGPE’s chemistry into greener, leaner forms. Good chemistry adapts, and PGPE’s versatility keeps it in the mix.

Glance at the ingredients on a cleaning spray or a paint can. Take a second look at the label on your favorite air freshener. You’d be surprised how often something called Propylene Glycol Phenyl Ether, commonly shortened by chemists to PPh, pops up. The name alone puts a lot of people off, and I get it—long chemicals often set off alarm bells. Yet, this ingredient clocks in as a real workhorse in manufacturing and home products, usually doing its job out of the spotlight.

One of the trickiest parts of making a good household cleaner or cosmetic is getting oil and water to work together, or making sure all the perfume and cleaning actives blend smoothly. PPh steps into this mess and keeps things mixed, dissolving oily dirt just as easily as it blends into water-based solutions. Think back to mopping up a greasy spill in the kitchen — water alone never gets it all. It takes something extra. PPh fills this role in many liquid cleaners, helping them lift grime and leave behind a fresh scent, rather than a film of oil.

Chemists value PPh in the lab and on the factory floor. In paint, it spreads evenly so colors don’t streak. In industrial coatings, it helps solvents do their job without leaving clumps. Perfumers love how it holds scents steady. Some cosmetic companies turn to it for gentle cleansing. Having formulated a few cleaning solutions myself, I’ve reached for PPh when simpler ingredients like plain alcohol or water just didn’t cut it, especially for greasy messes.

But the same knack for binding and blending means PPh doesn’t stay in one place. Concern pops up about what happens when it runs down the drain or lingers in the air after a fresh coat of paint dries. Europe, for instance, has set stricter guidelines, pushing some companies to look for alternatives or cap its use. That’s not just because of vague concerns. Too much exposure, especially in factories, links up with skin and eye irritation. Keeping workers safe takes more than gloves and masks — it’s about constant monitoring of air and careful training.

This all puts the spotlight on bigger choices in product design and chemical safety. Do we keep using a handy tool like PPh or start swapping it out for greener, less mysterious ingredients? The answer isn’t simple. Many safer alternatives cost more or work less reliably, which pushes up the price on store shelves — something families already feeling the pinch just can’t ignore. Product reformulation takes years of trial and error.

Better labeling and open information can at least trust users to make their own calls. I’d like to see more companies offer products without PPh for folks who worry about sensitivities, and encourage those who do use it to keep levels low. Push for transparency. Shelf life and cleaning power matter, but not at the cost of safety. If there’s anything decades in the business have taught me, it’s that chemical shortcuts come back to bite you—so if a gentler blend can do the job, it’s worth giving it a shot.

Browse through a bathroom shelf and chances are, you might spot “Propylene Glycol Phenyl Ether” buried in the tiny print on a lotion, a face cream, or even a liquid foundation. Most folks gloss over these scientific names, trusting that the products they buy have been vetted. Cosmetics use a cocktail of chemicals, and sometimes it takes a closer look to figure out what's cruising under the radar.

Propylene Glycol Phenyl Ether acts as a solvent. In plain terms, it helps blend ingredients, makes a product feel smooth, and can even stop things from separating in the bottle. Compared to ingredients with words like “parabens” or “phthalates,” this one rarely makes headlines. That’s not because it should get ignored.

I’ve met people with skin so sensitive, even switching laundry detergent can spark an outbreak. When it comes to skincare and makeup, the stakes are higher. Anything absorbed through the skin travels a different route in the body than something you’d eat or inhale. So, whatever promises brands make for their “gentle” or “hypoallergenic” lines, every ingredient counts.

Safety comes down to what research says and who’s doing the testing. Both the US Food and Drug Administration (FDA) and the Cosmetic Ingredient Review (CIR) Expert Panel have looked into Propylene Glycol Phenyl Ether. So far, they haven’t found evidence that the levels used in cosmetics lead to health problems for the majority of users. Most studies agree that it doesn’t build up in the body and gets broken down easily. At standard cosmetic concentrations, the science says it’s unlikely to cause harm in people without existing sensitivity.

But there’s another side to the story. The European Union restricts certain chemicals more stringently, and ingredient bans in the EU sometimes stir up questions about what Americans put on their skin. Propylene Glycol Phenyl Ether isn’t on their banned list, but that could change if more data arises. My own experience talking with dermatologists tells me that some people can react even to ingredients generally considered “safe.”

No one smears on a single lotion and thinks about what else they’ve layered, but our bodies might keep tabs. Each cosmetic doesn’t exist in a vacuum. Sunscreen, foundation, moisturizers—each product often contains similar “extras” like Propylene Glycol Phenyl Ether. Reactions like redness, itching, or rash pop up for a chunk of customers. For people with eczema, rosacea, or even just cranky skin, that’s enough reason to dig into the full label instead of just the front claims.

I decided a long time ago to patch-test anything new, even if it meant a tiny dab on the inside of the arm. This small habit can save a lot of trouble. The cosmetics industry thrives on customer trust. Brands would build stronger relationships by making ingredient lists easier to read and offering small samples. Regulators could ask for more studies on long-term, low-level exposure, not just one-off high doses.

Most people want to look good—and feel good—using the products they buy. Asking questions, backing decisions with data, and listening to what your skin tells you might just steer the industry toward safer choices for everyone.

I’ve crossed paths with plenty of chemical solvents throughout my years working around manufacturing and product formulation, but Propylene Glycol Phenyl Ether, also known by the less catchy name PPh, always manages to stand out. Folks working in paints, coatings, and cleaners call on it, and if you flip over a bottle under your sink or a can in your tool shed, you might spot its name hiding in the fine print. This chemical packs a punch when it comes to dissolving or breaking up stubborn substances, but there’s more to it than meets the eye.

Pour PPh into a glass and you’d see a clear, colorless liquid. It carries a faint, almost sweet scent—not enough to overwhelm, though you know it's there. This liquid doesn’t thicken like syrup, sticking close to the consistency of water, so it moves around easily during mixing or application. Boiling checkpoints around 240 °C tell you it’s not going to evaporate quickly, so it sticks around longer than water or even basic alcohols. It weighs just a little more than water, with a specific gravity around 1.06, so if you spill it your puddle will look and behave like water, too.

Mixing with water, on the other hand, goes only so far. You’ll get some blending, but not a seamless mix. If you’re blending it with other solvents or oils, it fits in much better. In real situations, this trait often means PPh shows up in jobs where a little water resistance comes in handy—unlike its cousin propylene glycol, which hugs water more closely.

PPh doesn’t throw tantrums. Left in a can or closed drum, it rarely reacts, which helps from a storage and transportation standpoint. Combining it with acids or strong oxidizers still demands common sense caution. In regular day-to-day handling, it won’t corrode your tools or chew through containers, so you get some peace of mind not having to fuss over every detail.

Its main claim to fame: being a mid-strength, slow-evaporating solvent. Add it to a paint, cleaner, or ink, and you’ll notice it lets formulas work a little longer, loosens dirt, and extends drying times. Plenty of applications take advantage of this trait to keep surfaces wet enough for even application or deep cleaning. The high boiling point also means it lingers longer on surfaces, spreading the workload out before vanishing.

Some folks take this chemical for granted, stacking it against more aggressive or volatile solvents. When you need something less flammable (flash point around 110°C), and don't want to stink up the room, PPh steps up. Its low odor lets manufacturers slip it into household and personal care products with fewer complaints from end-users.

Of course, like many chemicals, there’s no green light to splash it around without care. Direct skin contact can cause irritation, though it generally offers a lower risk profile than many older solvents. From experience, gloves and decent ventilation always beat learning the hard way. Waste management also comes into play: responsible disposal matters, since nobody wants residues sneaking into groundwater or building up in workspaces. Regional rules matter—a fact anyone who has worked in compliance soon realizes.

The story of Propylene Glycol Phenyl Ether always circles back to practicality. You find it again and again because it bridges the gap between effectiveness, safety, and flexibility. But nothing stays still for long—regulators keep an eye on solvents, and greener alternatives keep surfacing. Those of us who work with these substances, whether in research, product design, or on the shop floor, weigh these shifting sands every day.

Over the years, I’ve learned that simple mistakes with chemicals lead to big headaches. Propylene Glycol Phenyl Ether seems like a mouthful, and honestly, its risks add up fast if you don’t treat it with respect. Try leaving it in the wrong spot, and you might find your workplace filled with strange fumes or worse, a sticky mess that gets into places you’d rather not clean. A dry, well-ventilated area away from sunlight isn’t just nice; it keeps those chemical reactions from popping up at the worst time.

This stuff doesn’t get along well with moisture or strong oxidizers. So, skipping out on stacking boxes of bleach next to it actually saves a lot of hassle. From experience, warehouse folk sometimes think “out of sight, out of mind” applies, but with compounds like this, hidden is dangerous. Any container you use should have a solid seal and be made of materials that stand up to solvents — steel and high-quality plastics work best. I’ve seen seals degrade or drums bulge just from a bit of leakage or sunlight, making simple storage guidance worth following.

Anyone who thinks a quick job with this chemical doesn’t need gloves is setting themselves up for irritation. I once rushed through cleaning up after a spill, only to find my skin red and burning by lunchtime. Gloves rated for chemical resistance, splash goggles, and sometimes a respirator take the guesswork out. It doesn’t take a major spill for the vapors to start irritating noses and throats, especially in a cramped lab or workshop. Open windows or — better yet — a proper fume hood make a world of difference.

Those printed safety sheets aren’t just for compliance. They spell out what happens in an emergency, and I’ve watched teams avoid serious accidents just because someone read and remembered an emergency procedure. Eye wash stations and quick-drench showers seem like overkill, but in my career, a fast rinse has made a bad situation far less disastrous for a coworker exposed to chemical splashes.

Nobody plans for a spill, but acting like they're impossible isn’t an option either. Keep absorbent pads and neutralizers close by, not locked away where nobody can find them. Small drips wiped up right away keep a safe work area, and if a larger spill hits the ground, trained staff should be the ones controlling and cleaning up. Never dump this stuff down the sink. I’ve watched pipes corrode and local water regulators get involved, leading to expensive cleanups and lots of paperwork. Licensed disposal outfits know how to handle liquid waste appropriately, and they take a huge load off your shoulders.

It’s easy to skip steps with chemicals after a hundred normal days, and yet accidents always seem to land on day one hundred and one. Proper labels, adherence to safety protocols, and consistent housekeeping matter as much as any fancy engineering control. Each of us sets the example for everyone else who steps into the space, so respecting the hazards isn’t just smart — it’s the foundation for lasting workplace safety. The effort people invest up front, from the way they store containers to how they gear up before a quick job, pays off by keeping work flowing and bodies healthy. No shortcut or clever hack replaces a safety mindset.

Propylene Glycol Phenyl Ether, often found in formulations across different industries, doesn’t show up with a one-size-fits-all approach when it comes to containers. Most suppliers know that buyers might vary—from small labs looking for manageable bottles to manufacturers who want to ship drums or even truckloads. In my experience, figuring out how much to buy can get as technical as the projects the chemical itself goes into.

Starter batches and research-scale projects usually favor smaller bottles. Containers around 500 milliliters up to one liter tend to be the go-to among those running tests or sample blends, especially in R&D circles. These compact sizes usually come in high-density polyethylene (HDPE) or amber glass, which helps keep things stable and makes pouring less of a hassle. Anyone who’s tried to weigh out small quantities from a large drum knows how much easier these smaller bottles make things.

Scaling up brings its own set of problems and opportunities. Five-liter and ten-liter jerrycans bridge the gap nicely—they’re not too bulky for a bench but still let you get through a handful of production runs without running low. Carboys, typically around 25 liters, offer convenience for those who want to avoid constant reordering. These are the sizes I usually see in mid-sized manufacturing and university workshops. The materials for these containers nearly always lean plastic—HDPE is a favorite for the job since it stands up to the chemical without soaking up odors or turning brittle.

If we talk full-scale production, steel and HDPE drums dominate. Think 55-gallon (about 208-liter) drums lined up on warehouse floors, ready for forklifts and pallet jacks. Every major supplier I've dealt with lists these as their flagship packaging because larger buyers don’t want to fool around with refilling smaller bottles all day. Some operations even require IBC totes—those big, boxy containers holding up to 1,000 liters—making transport efficient for high-volume runs.

Packaging size isn’t just a logistical detail—it seriously impacts workflow and budgeting. Smaller bottles avoid waste and storage headaches for experimental projects. Mid-tier sizes cut down on frequent reordering, and big drums keep large factories moving. The packaging also affects safety, with factory-scale containers designed to handle leaks or rough handling. Improperly matched container sizes cause more spills and waste than most people think—problems get expensive in a hurry.

Anyone who’s tried to buy in bulk probably recognizes the headache of disposal and recycling. Getting rid of large drums or awkward jerrycans isn’t as simple as setting out the recycling bin. Some suppliers take back empty drums, but that policy rarely extends to the mid-sized jerrycans or carboys, which pile up in storerooms. More responsible packaging—refill programs, reusable drum liners, or better chemical-resistant recycling options—would ease the waste burden on everyone from research labs to manufacturing plants.

Demand for Propylene Glycol Phenyl Ether keeps shifting as new uses show up, and that means the packaging landscape could change as well. In my own experience, the best results come from suppliers open to flexible sizing or who take the extra step with environmentally conscious packaging. A little more customization in packaging sizes, especially options between 1 and 25 liters, still leaves a lot of buyers squeezed. Factories will always chase bigger drums for efficiency, but labs and small businesses deserve more tailored choices and less waste.

Everyday products often hide behind long, technical names. Propylene Glycol Phenyl Ether, or PPhE, is no stranger to this. Most folks have never seen it on a store shelf, but you’d be surprised how many of us brush up against it daily. The name might trip you up, but its uses spill over more industries than you might think.

You want a household cleaner that lifts grease and grime—to do that, companies reach for solvents. PPhE lands in many cleaning formulas because it tackles oily residues without leaving a harsh smell. In my experience, stronger solvents sometimes make my eyes water or trigger allergies. PPhE goes about its business quietly, with far less drama than many alternatives. Paints and coatings lean on this stuff too. Walk down a freshly painted hallway and notice how the paint managed to glide on smoothly and dry with an even finish—that’s a solvent doing its job. This chemical helps dissolve pigments and resins, creating the kind of finish people want on a living room wall or office desk.

Lotions, creams, and even some deodorants rely on more than just pretty scents and oils. They turn to PPhE to keep mixtures stable and comfortable on the skin. I’ve rubbed in more than a few creams that feel sticky or heavy—PPhE smooths that out, helping everything blend together. Some skin can protest against strong solvents, but formulas with this ingredient aim for a gentler touch. It shows up as a “solubilizer,” making it easier to combine oils with water, so you don’t get weird separation in your bottle.

Factories and workshops run on chemicals like this. Coolants and hydraulic fluids often get overlooked, but the machines in those shops need something to keep them from grinding to a halt. PPhE functions as a stabilizer or carrier fluid that keeps things running smoothly. Technical teams I’ve talked to swear by the importance of such additives, especially in places where metal meets metal and heat builds up. Its resistance to evaporation and ability to mix with tougher chemicals gives mechanics and engineers some breathing room in high-pressure settings.

If you read ingredient labels, you start to notice how many times PPhE appears. This isn’t just trivia—chemicals like this land in the spotlight because people want safer workplaces and cleaner homes. Regulatory agencies worldwide keep a close eye on solvents. PPhE scores points for being less hazardous than many older rivals, but it still comes with its own health rules. Workers handling it need gloves and proper air flow, and industrial plants must monitor emissions. I’ve sat in on safety meetings where even familiar chemicals get a fresh look when studies change or government agencies tighten limits.

No ingredient is perfect. The drive keeps going for safer, greener solvents. Some companies already hunt for even milder options or try plant-based blends in their cleaners and cosmetics. Replacement shouldn’t just mean less effective. A switch must deliver the same punch, or people won’t use it—no one wants a hand cream that curdles in the bottle or a paint that peels a month later. Looking at how PPhE functions helps everyone involved push for new solutions that check every box: safety, performance, and cost. Those changes don’t all come overnight, but steady research and feedback from workers and customers nudge the process along.

Staring down the back of a lotion bottle or a hand cream jar, you run into a parade of chemical names. Propylene Glycol Phenyl Ether—a mouthful to say—sometimes stands among them. Anyone living in modern society has come across it. It crops up in skincare, haircare, industrial products, even as a solvent in cleaning agents. The big question: should you worry if it touches your skin?

Science has done its share of heavy lifting on this one. Tests run by health authorities and independent researchers usually focus on irritation, allergic reactions, and absorption through human skin. Most studies show minimal irritation at low use concentrations. Cosmetic companies trust it for a reason—it’s good at dissolving tricky ingredients, spreads smoothly, and doesn’t carry a noticeable scent.

The US Cosmetic Ingredient Review panel looked at Propylene Glycol Phenyl Ether and gave it the green light for use in cosmetics, but with a few notes. Patch tests on healthy volunteers rarely show redness or allergic bumps at levels used in personal care. You’ll find similar findings from health authorities in Europe and Japan.

People react differently. Just walking through drugstore aisles reminds me how long it can take to find something that doesn’t make you itch or break out. Sensitive skin, eczema, or allergies throw a wrench in the works. A friend of mine can’t use half the moisturizers out there, even though most folks don’t bat an eye.

Propylene Glycol Phenyl Ether usually floats under the radar, but it’s not immune from triggering mild reactions. If you have a sensitive system, a patch test makes sense. Even ingredients considered “safe” at a population level can deliver unpleasant surprises to certain people.

Long-term exposure raises fair questions. No solid links tie this compound to cancer, hormone disruption, or other chronic issues at skin-care levels. Still, some folks worry because it flows across into industrial cleaning solutions. The dose makes the poison—a phrase that sticks because it’s true. The stuff sitting on your bathroom shelf contains a tiny fraction of what you’d find sloshing around a factory floor.

Keep in mind, the European Union keeps a close watch on new health data. If new problems pop up, they change the rules. Propylene Glycol Phenyl Ether remains allowed in regulated products, under concentration limits. That’s not the same as a free pass, but it speaks to real-world experience and ongoing monitoring.

Plenty of ways exist to keep skin in good shape while steering clear of ingredients that cause suspicion. Natural oils and plant-based solutions show promise for those who want to avoid synthetics. Reading ingredient lists carefully, doing the occasional patch test, and listening to your skin’s response makes a real difference. I’ve found that some products slip under the radar until my skin reminds me otherwise.

Everyday habits count for more than one ingredient on an ingredient list. Washing gently, using sunscreen, and not overloading the skin with new products help more than just dropping one chemical. Propylene Glycol Phenyl Ether doesn’t appear especially risky compared to many other additives, but paying attention is worth it. Health means staying tuned in, not living in a bubble.

Propylene Glycol Phenyl Ether pops up in a range of industrial uses—coatings, cleaning products, and even cosmetics. It doesn’t spark the kind of attention that volatile chemicals do, but you can’t just stash a drum of it anywhere. I’ve been around enough warehouses to know that some folks treat all “glycols” as harmless. That’s a recipe for headaches.

Chemical storage isn’t glamorous. The first urge is always to tuck stuff in the back where nobody bumps into it. With this ether, that’s risky. Over time, heat and sunlight make it degrade faster. I once saw a shipment left beside a window—after a week, the chemical picked up a yellow tint. That batch landed in hazardous waste. So reliable storage means a cool, shaded room, away from direct sun and far from any heat sources like boilers or radiators.

Anyone who’s worked in a shop knows what spills mean. Propylene Glycol Phenyl Ether isn’t corrosive, but it seeps into concrete and sticks around in small cracks. Standard steel drums with tight-sealing lids work. Polyethylene drums offer a good alternative. I stick warning labels on all sides, because new staff often mix up containers. Making sure the drum caps actually close and seal tight cuts down on leaks and vapors.

Good air flow helps. Even though this ether doesn’t have a heavy odor, vapors add up in cramped corners. I’ve set up floor fans in stuffy storage rooms just to keep the air moving, pretty much as a rule. Keeping one’s work area clean pays off, too: a small rag soaked with this stuff left overnight will stink up a whole storeroom.

Chemicals don’t need to react with each other to cause trouble. Storing propylene glycol phenyl ether next to acids or strong oxidizers turns routine handling into something dangerous. I saw a near-miss once with a bottle of bleach stacked right above a can of ether—one quick slip could have meant a call to the emergency team.

Lower temperatures help slow down degradation. Between 15 and 25 degrees Celsius hits the sweet spot. Electric space heaters or exposed pipes drive those numbers up, especially in winter, so basic thermostats act as cheap insurance. While this ether isn’t super-flammable, enough of its vapors in the air near a spark make for a nasty surprise. Storing it away from forklifts, welding stations, or hot lights goes a long way.

On the job, I’ve had colleagues ask if they can handle this ether without gloves. I won’t recommend that. Some skin irritation or mild headaches come from short exposure. Nitrile gloves and simple goggles work fine, and keeping a sink nearby for a quick rinse adds peace of mind. I once got a splash on my hand; a day later, my skin felt tight and dry. Nothing dire, but not pleasant. The safety data sheet calls for this gear for good reason.

It’s tempting to view chemical storage as simple logistics, but skipping the basics—ventilation, temperature control, proper labelling—always backfires. Setting aside a single shelving unit for just propylene glycol phenyl ether, using labeled, tight-sealing containers, and checking caps after every transfer has saved me trouble more than once. Setting up a weekly walk-through gets a bad rap for being tedious, but finding a cracked drum or a forgotten rag beats dealing with a full spill or a health scare.

Ask anyone who works with solvents or specialty chemicals, and they'll tell stories about finding the right balance between strength and safety. Propylene glycol phenyl ether, with its mouthful of a name, puts itself right in the middle of this search. This colorless liquid doesn’t grab headlines, but if you ever checked ingredient labels for cleaning products or coatings, you’ll spot its fingerprints.

First off, propylene glycol phenyl ether has a mild, somewhat sweet scent. You won’t feel overwhelmed by its aroma, which makes a big difference on long workdays in industrial labs or workshops. Pour some out and it rolls across surfaces in a controlled way, with a viscosity higher than water but without the heaviness you get from syrupy liquids.

Its boiling point lands at around 242°C (about 468°F), meaning it doesn’t disappear into thin air as quickly as other solvents. This property allows manufacturers to use it where slower evaporation supports even application, such as in paint and ink production. At room temperature, you won’t see it crystallizing or turning cloudy; it stays clear and stable.

Chemically, propylene glycol phenyl ether holds both hydrophilic and hydrophobic tendencies. In plain English, it gets along with both water and oil-based mixtures, making it handy for blending ingredients that would otherwise refuse to mix. In the cosmetics world, you’ll find it contributing to smooth lotions and creams, helping fragrances and oils dissolve evenly.

The chemical structure—one part propylene glycol, the other part phenyl ether—gives it stability under routine storage conditions. It rarely kicks off wild reactions unless paired with strong acids or oxidizers, which most people don’t leave lying around in their homes. Its mild reactivity keeps it from breaking down or changing character in most ordinary settings.

Walking through a hardware store or market, shelves brim with products claiming streak-free glass, durable paint, easy-to-wipe surfaces. Behind these promises, propylene glycol phenyl ether plays an understated role. Its low toxicity and easy biodegradability put it ahead of many old-school solvents. According to safety sheets, skin exposure doesn’t lead to harsh burns or lasting irritation for most adults. That being said, sensible handling and gloves always make sense with any chemical.

One big reason many industries lean on it: regulations around worker safety keep tightening. Alternatives like ethylene glycol ethers linked with strong health risks fell out of favor. Propylene glycol phenyl ether stepped in as a middle ground—strong enough for commercial uses, less risky than much of what came before. European and U.S. agencies list it as a safer solvent, and this status pushed adoption further, especially in indoor products.

No chemical gets a free pass, and the growing focus on environmental footprints stretches into every factory and lab. Questions remain about breakdown by-products and long-term impacts on water supplies. Researchers push to understand exactly what trace amounts might mean once this chemical travels through drains. These studies drive producers to tweak formulations, lower concentrations, and push recycling or recovery efforts.

At the end of the day, propylene glycol phenyl ether isn’t just a background piece in the chemistry set. Its blend of stability, safety, and versatility lets both big businesses and small startups build safer, longer-lasting products. Anyone curious about tomorrow’s materials should keep an eye on how chemicals like this evolve, nudging us toward better balance between performance and responsibility.

I’ve spent years in labs where questions about mixing chemicals don’t just belong on a whiteboard—they show up during batch production, and mistakes get expensive. Propylene Glycol Phenyl Ether, or PPhE, often lands on these ingredient lists. Its appeal comes from being both a solvent and coalescent. It handles water-based and oil-based systems with a kind of versatility that makes formulating easier. That's one of the big reasons plenty of coatings, paints, and cleaning products managers vouch for it. Yet, the real trick isn’t just picking a solvent—it’s picking the right friends for it in a mixture.

Formulating with PPhE isn’t about dropping it blindly into a liquid and calling it a day. You find yourself looking at ingredient labels from a practical standpoint: will this blend turn cloudy; will it separate overnight? I remember handling batches where the wrong choice of surfactant left us with sludge at the bottom of what should have been a clear solution. That’s nothing but lost time and money.

Ethylene glycol ethers, alcohols, and some glycols play nice with PPhE. They mix clear and hold stable. On the surfactant side, non-ionic types—think alcohol ethoxylates—tend to work without fussing. Ionic surfactants, especially anionics, can give problems. The mixture could turn hazy or spit out precipitation, and you only notice it later unless you’re paying attention to compatibility charts or doing bench tests.

Anyone formulating in cleaning products knows consumers don’t want to see separation in a spray bottle on the shelf. In coatings, instability in the mix can wreck application, film formation, or drying time. These aren’t rare events—manufacturers have had to recall batches or scrub entire production lines to fix avoidable mistakes in mixing.

Let’s talk money and efficiency. Say a paint plant rolls out a thousand liters of emulsion and the solvents aren’t compatible. Not only does it waste raw material, but operators also spend hours troubleshooting. This kind of loss shows up on the bottom line, not to mention customer complaints or lost contracts if the results disappoint.

I learned early to run a small jar test before betting thousands on compatibility claims in supplier literature. Mix up a sample, stir it, and let it sit for a few days at room temperature, sometimes in the fridge, sometimes near a window. Watching for phase separation, texture changes, or cloudiness tells more than spec sheets. If you can, lean on HLB values (hydrophilic-lipophilic balance) for surfactants and keep within a targeted range based on experience—usually between 8 and 14 for blends aiming for clear, stable results in water-based systems.

There’s no skipping the basics. Double-check the Material Safety Data Sheet. Track the pH, temperature sensitivity, and recommended dosages. Manufacturers should share compatibilizer recommendations, but their interests don't always match yours. Tap into your supplier’s technical support; field reps have seen enough disasters to offer advice rooted in real-world mistakes.

At the end of the day, mixing chemicals isn’t guesswork—it’s creative problem solving fueled by curiosity, frustration, and the stubbornness to avoid repeating avoidable errors. Propylene Glycol Phenyl Ether sits on my short-list of reliable solvents, and with only a bit of upfront checking, it blends well and keeps headaches to a minimum.

| Names | |

| Preferred IUPAC name | 1-Phenoxypropan-2-ol |

| Other names |

PPH Propylene glycol monophenyl ether Phenoxypropanol 1-Phenoxy-2-propanol 1-Phenoxypropan-2-ol |

| Pronunciation | /ˈprɒpɪliːn ˈɡlaɪkɒl ˈfiːnɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 770-35-4 |

| 3D model (JSmol) | `/data/cml/mol/6c0/6c0cd9b0e237873d61bb64abd0c4f1138c5fd2553a621bac0297067cee397ceb/propylglycolphenyether-mol.jsmol` |

| Beilstein Reference | 3698738 |

| ChEBI | CHEBI:8807 |

| ChEMBL | CHEMBL162267 |

| ChemSpider | 15405 |

| DrugBank | DB13957 |

| ECHA InfoCard | echa.europa.eu/substance-information/-/substanceinfo/100.014.285 |

| EC Number | 603-098-00-9 |

| Gmelin Reference | 102180 |

| KEGG | C14320 |

| MeSH | D017350 |

| PubChem CID | 7796 |

| RTECS number | KL8050000 |

| UNII | 6DC9Q167V3 |

| UN number | UN3082 |

| CompTox Dashboard (EPA) | DTXSID2020147 |

| Properties | |

| Chemical formula | C9H12O2 |

| Molar mass | 194.24 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Faint, aromatic |

| Density | 1.06 g/cm3 |

| Solubility in water | 0.27 g/L (20 °C) |

| log P | 1.16 |

| Vapor pressure | 0.02 mmHg (20°C) |

| Acidity (pKa) | 15.30 |

| Basicity (pKb) | 14.13 |

| Magnetic susceptibility (χ) | -10.11 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.513 |

| Viscosity | 25 mPa·s (25°C) |

| Dipole moment | 2.76 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 395.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -452.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5720.7 kJ/mol |

| Pharmacology | |

| ATC code | D02AX10 |

| Hazards | |

| Main hazards | Causes serious eye irritation. Harmful if swallowed. Harmful in contact with skin. Harmful if inhaled. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P264, P270, P301+P312, P330, P501 |

| Flash point | 110 °C |

| Autoignition temperature | 279 °C (534 °F; 552 K) |

| Explosive limits | Upper 5.6%, Lower 1.1% |

| Lethal dose or concentration | LD50 oral rat 3,600 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3,000 mg/kg (oral, rat) |

| NIOSH | RN 770-35-4 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 50 mg/m³ |

| Related compounds | |

| Related compounds |

Ethylene Glycol Phenyl Ether Propylene Glycol Methyl Ether Dipropylene Glycol Phenyl Ether Propylene Glycol Ethyl Ether Ethylene Glycol Monoethyl Ether |