Chemical breakthroughs always mirror the changing needs of the world. Propylene Glycol Dimethyl Ether (PGDME) grew out of the twentieth century’s hunger for better, safer, and more efficient solvents. Lab notebooks from the late 1960s indicate that organic chemists, always in a race to outdo the limitations of ethereal solvents, began tinkering with variants. PGDME quietly made its mark as scientists in Europe and Asia sought an alternative that dodged both volatility and regulatory headaches. The push from industry arrived as some early solvents drew criticism for toxicity or environmental problems. PGDME stepped forward as something different: strong enough for rigorous industrial work, but that also followed newer safety standards. The substance’s route from chemical curiosity to industrial staple took a few decades. Growth ramped up after the 1980s, with international chemical suppliers listing it in specialty catalogs and expanding its production to keep up with demand from the electronics and pharmaceutical sectors.

People often ask, why bother with this chemical rather than using the older standbys? PGDME brings a set of features prized in labs and factories. As a colorless, low-viscosity liquid, it slides easily into processing lines. Its faint, sweet odor doesn’t draw complaints like some other ethers. Anybody who has watched technicians load solvent tanks will notice its handling advantage — no choking fumes and no tendency to form sticky residues. Bottles marked with its CAS number, 111109-77-4, pop up in an array of environments, from bench-scale research all the way to full production. It isn’t a new molecule by world standards, but it keeps drawing attention each time industries wrestle with solvent choice. The conversation usually turns to safety, purity, and performance.

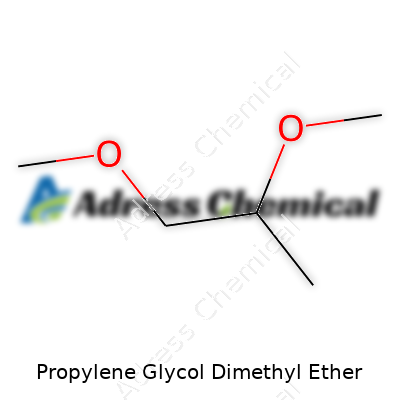

Every chemist gets curious about the numbers, so here’s a straightforward list. PGDME lands at a molecular weight of about 134.18 g/mol. Its boiling point floats around 85-90°C at normal pressure, and it weighs in with a density of roughly 0.87 g/cm³. That moderate boiling range helps as you can distill it or recover it without complex setups. It enjoys good solubility in water and most organic solvents, though not to the degree of the original glycols people tried a century ago. As for stability, leave it capped in an ordinary lab and it stays true for a respectable shelf life, resisting breakdown under standard light and temperature. It carries the dual methyl ether groups, which keep it less reactive than classic ethers and improve shelf stability.

Industrial buyers check for standards. Reputable suppliers ensure PGDME meets at least 99.5% purity. Key impurity profiles include water content, acid number, and presence of peroxides — PGDME earns marks for rarely picking up much water or acid in transit. Labels must state hazards in line with GHS labeling rules, listing flammable liquid and warning against inhalation. I’ve seen most drums and laboratory bottles come with clear instructions for storage: keep away from ignition sources and avoid long-term exposure to air. Some European and North American suppliers detail trace metal content, especially when the user pool includes electronics manufacturers who care about every last ion.

Making PGDME takes care but follows a clean synthetic plan. Manufacture starts with propylene glycol and dimethyl sulfate or, in modern settings, with methylating agents that follow greener chemistries. This route sets PGDME apart from old-school ethers made with less discriminating methods. Industrial reactors crank out the product, then distillation columns pull out the unwanted bits, so you get tight purity controls. My visits to two mid-sized chemical plants in Asia showed crews running this process on a closed loop, with air scrubbing and solvent recovery keeping emissions within legal limits.

PGDME holds up under basic workhorse applications where other ethers may break apart. Typically, it survives exposure to moderate bases and acids. It doesn’t stand up well to strong oxidation — like most ethers, mixing with powerful oxidizers could end poorly. Research groups found that PGDME acts as a good participant in alkylation reactions, and even as a phase-transfer agent in some organic syntheses. Subtle tweaks to its structure can create derivatives for specific uses, but most commercial users demand the unmodified form due to its predictability and reliability.

Every catalog tells the same story but uses different words. Among scientists, PGDME stands for Propylene Glycol Dimethyl Ether, but labels may also read 1,2-Dimethoxypropane, or DMP. Some older literature refers to it as PGDME or simply propylene glycol methyl ether, though this can blur the distinction from related chemicals. Keeping the naming straight prevents accidents, which I learned working at a specialty chemicals distributor. Clear labeling saves a lot of hassle during audits and when training new technicians.

People always look for safety red flags, and PGDME gets a lot less scrutiny than older ethers, though caution still matters. Its flashpoint hovers around 10-13°C, so regular folk should treat it with the same respect given to other common flammable solvents. I’ve talked to lab staff who appreciate that it doesn’t form peroxides nearly as quickly as diethyl ether, but container caps shouldn’t sit open. Most facilities require modest PPE: gloves, goggles, and fume hoods, and bulk transport always takes place in UN-approved drums. Safety data sheets urge workers to keep the liquid off skin and to avoid inhaling vapors during transfers. Storage rooms need good ventilation. In spill scenarios, standard absorbent methods take care of minor leaks, but fire protocols come into play quickly due to flammability.

PGDME covers ground in several industries. Electronics manufacturers like using it as a solvent for lithium-ion battery electrolytes thanks to its low reactivity and decent conductivity. Its role in the paint and coatings sector keeps expanding because it thins coatings smoothly and then flashes off without leaving film defects. In the lab, synthetic chemists employ it both as a reaction medium and as an extractant for specialty separations where other solvents fall short. I once helped a research group troubleshoot a stuck pharmaceutical process and switching from a generic ether to PGDME unblocked the yield. Its growing acceptance in green chemistry circles suggests that we’ll keep seeing it substituted for less environmentally friendly options.

Research on PGDME has picked up lately, with focus on both new applications and safer production techniques. Patent databases reveal a flurry of interest from battery tech companies and pharmaceutical developers. Scientists continue testing how PGDME performs as a safer alternative in syntheses where old ether solvents showed poor stability or risky toxicity. One area receiving a lot of attention is its compatibility with next-generation materials, particularly those that need non-reactive, water-miscible solvents. Waste minimization stands out in recent R&D, aiming to close the loop on solvent recovery and reuse, lowering both cost and risks.

People want transparency on potential health risks, and PGDME attracts scientific scrutiny because it's less notorious than many traditional ethers. Studies run by independent labs and government safety boards show moderate toxicity. Rats exposed to high concentrations developed mild symptoms, but only at doses way above any workplace exposure limits. Workers exposed over years reported no unusual health trends in several workplace wellness surveys. Still, as with any organic, long-term impacts don’t stand fully revealed, so industry best practice mandates air monitoring and regular review of occupational thresholds.

Companies face relentless pressure to find safer, greener solvents, and PGDME sits among a shortlist gaining ground. Next-generation battery makers have highlighted its role in optimizing electrolytes, while pharmaceutical teams view it as a reliable stand-in for problematic ethers. More green chemistry startups are putting PGDME through life-cycle assessments to document carbon footprint reductions. As regulatory and environmental scrutiny grows, it’s likely that PGDME will attract even more interest, pushing researchers to improve its recovery, scaling methods, and possibly unlock new modifications. Given the chemical’s mix of performance, safety, and adaptability, most signs point to increasing market growth—especially as governments tighten rules around old ethers and raise the bar for solvent sustainability.

Propylene glycol dimethyl ether, sometimes listed as PGDME, grew into a topic of interest for many industries over the last few decades. Chemists don’t always get a say in which solvents make headlines, but PGDME stands out as a common choice in labs and factories for good reason. This compound helps unlock plenty of chemical reactions that make up our everyday products, though most people never even hear its name.

PGDME works especially well as a solvent for chemical reactions and product formulations. Many working in laboratories reach for it because it dissolves salts and other tough substances, far better than more pedestrian solvents. When working with lithium batteries, for example, PGDME helps in shaping the delicate chemistry inside. Its ability to dissolve electrolytes cleanly and with little fuss has made it a go-to for the battery world. I remember a project in university where PGDME allowed our group to skip several frustrating workarounds, just because it played so nicely with our experimental compounds. Without it, we would likely have burned more hours and resources than we could afford.

Another area where PGDME finds its purpose is in coatings and specialty inks. Ink manufacturers lean on it because of its consistent evaporation rate, which allows precise control in printing and electronics. For anyone who’s tried to troubleshoot an ink formulation, a solvent that doesn’t throw curveballs counts as a small miracle.

PGDME offers a less toxic profile compared to some older, more dangerous chemical solvents. Nasty compounds like benzene used to hold a top spot, until researchers and workplace safety experts forced a change. Now, companies want to use solvents that not only work but cause fewer problems for workers. PGDME brings that benefit, cutting down on hazardous risk, both in handling and in the air. Factories don’t need as many special ventilation procedures or full-body protection, compared to what was required in the past. A safer workplace means fewer sick days and less panic at accidental spills.

Still, every chemical brings challenges. One problem is disposal. After it serves its purpose, PGDME can’t just get rinsed down the drain. In areas with few waste-handling options, labs and plants must plan carefully. Some have shifted to collecting and recycling spent solvent, which helps minimize pollution and keeps costs bearable. Regulations keep tightening, and anyone in the field stays alert for new disposal guidelines. As a researcher, I’ve watched waste management turn from an afterthought to a budget line, and that push has actually improved how groups choose and use their solvents.

Another issue is over-reliance. Once a solvent like PGDME proves itself, teams can forget to question whether a greener or cheaper alternative exists. Continuing education and sharing real-world lab experiences helps nudge professionals out of their comfort zones. In my experience, group meetings where techs and chemists compare notes on process tweaks help shine a light on possible improvements.

The story of PGDME echoes that of many modern chemicals—helpful, safer than old-school options, but not perfect. A push towards greener chemistry encourages more careful use and ongoing innovation. Researchers lean on it for good reasons, but thoughtful disposal, health tracking, and a willingness to rethink processes keep its place in the toolbox fresh and responsible.

Most people don’t wake up thinking about chemicals like Propylene Glycol Dimethyl Ether. For folks in a lab or industrial setting, though, this isn’t some faceless substance. It’s a solvent, clear as water, with a slightly sweet smell. In many workspaces, folks handle it because it does a good job dissolving both polar and nonpolar things, so it pops up in coatings, electronics, and plenty of lab reactions. Dealing with it means respecting what it can do—not just in those beakers, but to your skin, lungs, and work area, too.

Spend any time in a chemical lab, and someone will remind you: fumes matter. Propylene Glycol Dimethyl Ether can slip into the air and irritate the eyes, nose, or throat. Fume hoods aren’t just a box to stash glassware; they’re the first defense between lungs and solvents. I’ve watched what happens when folks ignore this—it starts with coughing or watery eyes, and that’s just at lower levels. Closing the sash, turning on the airflow, and double-checking that the exhaust fan actually works should be part of the daily ritual—less about rule-following and more about keeping headaches and sick days away.

Hands love to forget what they touch. For Propylene Glycol Dimethyl Ether, bare skin won’t do. Some gloves just can't keep this stuff out. From my time working with solvents, nitrile makes a solid shield—latex doesn’t cut it, and vinyl stands little chance. Goggles stop those careless splashes and keep eyes from smarting for the rest of the shift. Splashes aren’t rare. Sometimes it’s one pipette or one bump of a flask, and suddenly there’s stinging. Never feels worth it after the fact, especially since the right gear sits just a few steps away.

Accidents don’t wait for a checklist. Once, I watched a careless twist of a cap turn into a slippery mess across the bench. People think a roll of paper towels helps, but that only spreads trouble. Spill kits with absorbent pads and neutralizing agents save the day and the cleanup. Keeping the solvent in tight-sealed, labeled containers keeps confusion low. Nothing good comes from mystery bottles or leaky lids. Flammable cabinets aren’t just big yellow ornaments—they’re the right spot for this kind of liquid since its vapors can catch fire fast on a hot afternoon or near an unwatched hotplate.

Eating lunch after handling solvents has never ended well for anyone. Propylene Glycol Dimethyl Ether isn’t acutely toxic by a single touch, but it collects in the body over time and can mess with the liver and kidneys. That sandwich tastes a lot better without a trace of solvent flavor. Washing hands before grabbing a snack or heading home breaks the chain. In shared workspaces, labeling bottles, wiping down benches, and tossing out contaminated gloves keep everyone out of trouble—most accidents happen because someone left behind a bit of the last job.

No one is born knowing chemical safety—it’s something you pick up from mentors, short courses, or those persistent safety posters taped above the sink. Safety Data Sheets sit at hand in every responsible lab, and reading beyond the risk codes makes a difference. It’s easy to forget a detail or two, especially after months of routine. Refreshers don’t take hours—they take a reminder, a quick read, or a short meeting over coffee. Everyone benefits from trading stories about close calls, because those lessons stick longer than anything buried in the fine print.

Propylene glycol dimethyl ether sounds like one of those lab chemicals most people ignore on ingredient lists. Still, in real jobs from industrial cleaning to electronics manufacturing, it shows up more often than folks realize. Breaking it down, the word "glycol" signals a relationship to the stuff found in many household products, from antifreeze to skin creams. Oddly enough, even seasoned workers sometimes pause to ask — does it actually mix with water, or will it float and separate like oil on soup?

This ether carries a couple of methyl groups (think tiny carbon-heavy appendages) and a chain based on propylene. In practice, that shape means something important: propylene glycol dimethyl ether dissolves pretty easily in water. The science nerds call it "miscible". For anyone who’s tried to mix oil and water before, they know this isn’t always obvious. That methyl and ether pairing could’ve tipped things out of balance, but the glycol part strikes a bargain with the water molecules.

On the factory floor, solubility can make or break a cleaning job. Once, I watched a colleague try to strip residue off a piece of metal. A chemical that mixes with water washed away quickly, leaving almost no streaks. Another time, someone picked the wrong solvent and ended up with gummy build-up. Folks in pharmaceuticals or electronics don't get a free pass either — solvents that don't dissolve well usually complicate cleanup, or worse, wreck the batch.

Chemistry textbooks will talk up molecular structure, dipoles, and hydrogen bonds as the reason some things mix well and others fight it. But on the floor, results matter more than theory. Mix up propylene glycol dimethyl ether with water and you don’t see weird layers, and cleanup at the end happens with less elbow grease.

Facts show it comes with a boiling point near 83°C — a useful tidbit when evaporation rate matters in a lab or on a production line. Unlike heavy, stubborn oils, this one disappears pretty quickly with a bit of heat, and it doesn’t leave much behind. That adds up to speedier work and less waste.

No story about an industrial solvent should overlook safety. The fact that propylene glycol dimethyl ether mixes easily with water does not put it on par with safe kitchen staples. Even though solubility helps with rinsing, this chemical brings some fire risk, and it’s wise to run vent fans or crack open a window. Just because something isn’t making waves or floating on top doesn’t mean it’s harmless. Clear operating procedures, not shortcuts, lower risk.

Some sites stick with this solvent for its easy cleaning, but it’s worth checking local regulations and health charts. As safety standards tighten and green chemistry gains steam, engineers keep their eyes open for non-flammable, low-toxic replacements. Water-based eco-solvents have come a long way and can sometimes swap in with minor adjustments, especially on sites with tighter emissions rules or worker health concerns.

Each choice should fit the job at hand. In the end, good results come from picking the right solvent, knowing its properties, and using it with some common sense – not just strong chemicals, but solid decisions.

Propylene Glycol Dimethyl Ether, often called PGDME by lab folk, boils at around 83 degrees Celsius (181.4 Fahrenheit). That number may not turn many heads at first glance, but it’s important to anyone who deals with solvents, lab safety, or chemical engineering. I’ve seen enough to know the headaches that come with misjudging how easily something turns to vapor. Your workspace changes quickly when you miss a detail like this.

Solvents are everywhere: paint shops, research benches, even in electronics repair. A lower boiling point like PGDME’s means you’re looking at quick evaporation and fumes. This isn’t just a technical footnote you’d see in a safety sheet—it's a practical concern for ventilation and fire safety. Once, a colleague underestimated a solvent’s volatility, and our lab ended up with an evacuation triggered by an unexpected vapor cloud. A bit more attention to boiling points could have saved a lot of time (and stress).

PGDME’s boiling point influences where and how it gets used. It evaporates more easily than water, so it finds a place in cleaning electronics, ink formulations, and specialty coatings. If it lingered instead of flashing off, you’d end up with sticky residues or delays in production. I’ve worked with adhesives that rely on solvents like this one—the speed at which they leave the surface can spell the difference between a clean bond and a mess.

Compare this with solvents sitting higher up the temperature chart. Those may stick around longer, and sometimes that’s the point—slow, even evaporation for a controlled effect. In cases when speed matters, chemists pick PGDME and its relatives to get the job done quickly and cleanly. The trade-off comes with its own risks, especially when users ignore how easy it is for these vapors to gather in a room, waiting for one stray spark.

This solvent’s relatively low boiling temperature means it vaporizes fast and spreads through the air with ease. Workers need proper training and, most of the time, better ventilation than old buildings usually offer. Too many people shrug off vapors as just a nuisance until someone gets dizzy, or worse. That’s why chemical storage and handling guidelines hammer home the point: know the boiling point, respect it, and use the right equipment.

There’s also an environmental side to the story. Volatile solvents escape into the air, bringing up air quality issues and headaches for regulators. Every year, new rules ask industry to keep emissions in check, pushing manufacturers toward catching more fumes or switching to alternatives with lower emissions.

People working with PGDME or similar solvents benefit from better airflow and leak-proof containers. It helps to install vapor detectors and use good-quality respirators when working in tight spots. Some companies already recycle their solvent vapors, cutting waste and protecting workers at the same time. Research keeps pushing for greener options—safer substitutes with less tendency to evaporate and fewer harmful effects if inhaled.

Boiling point seems small on paper, but experience drives home its weight. A little extra care goes a long way—better for users, better for the planet, and better for the bottom line in the long run.

Anyone working with Propylene Glycol Dimethyl Ether, often called PGDME, has probably noticed that handling this chemical isn’t as simple as storing paint thinner in the garage. I remember the first time I opened a barrel of PGDME at the warehouse: a sharp, unmistakable odor hit me, and the label’s hazard icons made it clear this stuff asks for respect.

Heat seems harmless until you’re talking about flammable solvents. PGDME likes to catch fire, so hot storage sheds or cramped equipment rooms spell trouble. I used to think an ordinary steel drum in a corner would do the job, but after hearing about a warehouse fire caused by a similar solvent sweating in the heat, I changed my view. Cool, shaded spaces—not next to the boiler or any place where sunlight cooks the air—make a difference. Room temperature works, as long as you avoid swings that create condensation inside containers. Water slipping in taints the chemical, and that isn’t just wasteful; it’s dangerous.

I’ve watched plastic drums left open, their contents slowly vanishing. PGDME evaporates in a flash. Tight-fitting lids and sealed drums keep the solvent inside and air (with all its moisture and wild contaminants) outside. Even small leaks turn into strong fumes that make the air hard to breathe and invite explosions if sparks fly. Sometimes people get casual, thinking a loose cap isn’t a big deal, until they stumble across puddles beneath a drum that should’ve lasted the whole quarter.

Solvents start trouble when they mix with oxidizers, acids, or even old cleaning rags. After seeing a storage area where acids and solvents huddled together “just for a day,” I realized that shortcuts like this put everyone at risk. Wherever PGDME rests, keep it apart from things that feed fires or trigger chemical reactions. Flammable liquids need their own spot, away from oxidizers, sparks, and workers eating lunch nearby.

Labels fade, warning signs collect dust, but the real weak link is carelessness. Training goes much further than laminated binders. Rolling out refresher demos, drilling what to do in a spill, and making sure new staff get to know the sharp bite of PGDME’s odor—those details count. Some companies install continuous ventilation, but a fan means nothing if barrels get stacked in dark corners where air barely moves.

Spill kits with absorbent pads and chemical-resistant gloves need to sit within arm’s reach, not locked away at the other end of the site. Over the years, I’ve watched seasoned workers ignore these supplies until one bad day forced them to scramble. Simple steps, like writing the date on the drum or logging container checks, sidestep old-stock problems and surprise leaks.

No one wants to live through a solvent accident. Storage comes down to common sense—cool rooms, sealed containers, safe neighbors, and staff who know what to do without needing a manual every time. Regulations help set the standard, but daily habits keep everyone safe. If you treat PGDME with the same care you’d give a barrel of gasoline, you’re on the right path.

| Names | |

| Preferred IUPAC name | 1,2-Dimethoxypropane |

| Other names |

1,2-Dimethoxypropane DMP PGDME Dimethyl propylene glycol Propylene glycol methyl ether |

| Pronunciation | /ˈprɒp.ɪ.liːn ˈɡlaɪ.kɒl daɪˈmiːθɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 110-71-4 |

| Beilstein Reference | 1460600 |

| ChEBI | CHEBI:80990 |

| ChEMBL | CHEMBL157150 |

| ChemSpider | 12013 |

| DrugBank | DB14010 |

| ECHA InfoCard | 100.036.856 |

| EC Number | “203-718-2” |

| Gmelin Reference | 7662 |

| KEGG | C19601 |

| MeSH | D017206 |

| PubChem CID | 8095 |

| RTECS number | JM8925000 |

| UNII | DU8M9JY7V8 |

| UN number | UN3271 |

| Properties | |

| Chemical formula | C5H12O2 |

| Molar mass | 134.18 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | sweet odor |

| Density | 0.866 g/mL at 25 °C (lit.) |

| Solubility in water | miscible |

| log P | -0.36 |

| Vapor pressure | 0.7 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 43 |

| Basicity (pKb) | pKb: 4.5 |

| Magnetic susceptibility (χ) | -10.05×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.377 |

| Viscosity | 1.2 mPa·s (20 °C) |

| Dipole moment | 2.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 370.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -413.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3930 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 52°C |

| Autoignition temperature | 160 °C |

| Explosive limits | 1.5-17.5% (V) |

| Lethal dose or concentration | LD50 oral rat 5,400 mg/kg |

| LD50 (median dose) | 5,300 mg/kg (rat, oral) |

| NIOSH | RN 1,2-Dimethoxypropane 1320 |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Dimethoxyethane 1,2-Butylene glycol dimethyl ether Diethylene glycol dimethyl ether Ethylene glycol dimethyl ether Triethylene glycol dimethyl ether |