Looking back, the chemical industry started exploring polyether compounds not just for the sake of innovation, but because these materials solved practical problems in labs and factories. After the rise of ethylene oxide chemistry in the early 20th century, people noticed that adding repeating ethylene glycol units produced a group of clear, water-soluble, low-volatility liquids. Pentaethylene glycol monomethyl ether, as part of the poly(ethylene glycol) monomethyl ether family, found a place once chemists realized it could act as both a solvent and a building block. Teams in the 1960s and 70s published early syntheses, mixing practical needs for good solvency with a drive to stretch what polymer chemistry could do. The compound’s chemistry saw steady refinement, mostly driven by industries looking for safer, more predictable solvents.

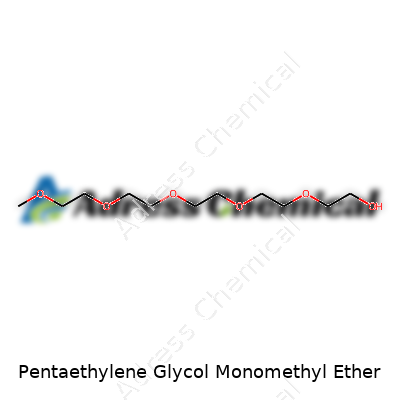

Pentaethylene glycol monomethyl ether, often sold under names like MPEG-5 or PEG5ME, combines five ethylene glycol units with a terminal methyl group. Suppliers bottle it up as a colorless, viscous liquid, not something flashy, but it manages to power through many challenging jobs thanks to its solubility and low reactivity. This compound stands among other glycols as a mid-size member, bigger and heavier than common glycols yet skilled at balancing water and oil solubility. I once handled a drum of this stuff for a coating project—it pulled together pigments, binders, and additives that refused to play nicely in cheaper solvents.

Pentaethylene glycol monomethyl ether sits on the lab bench as a thick, slightly sweet-smelling liquid. It weighs around 242 g/mol, and its boiling point ticks up above 270°C, so it sticks around for high-temperature work. It absorbs water but won’t instantly turn sticky in humid air. That balance of solubility means it can dissolve dyes, resins, gums, and inorganic salts that would wreck typical organic solvents. Chemicals resistant to oxidation or hydrolysis tend to stick around longer in solutions of this ether. In a pinch, its relatively low toxicity and slow evaporation also deliver some peace of mind to workers digging up old resin stains or stubborn industrial fats.

You find this ether labeled with its CAS number 1947-14-6 and molecular formula C11H24O6. Most suppliers ship it above 99% pure. Safety labels highlight possible mild skin and eye irritation. I remember reviewing a datasheet emphasizing the need for basic gloves—nothing too extreme, but a reminder this stuff isn’t a hand lotion. Packaging usually means sealed drums or jerricans, with hazard pictograms for low acute toxicity and combustible liquid status. Technical data often documents refractive index, water content (down to parts per million), and residue on evaporation. That kind of specificity reassures buyers that batches will perform predictably in all sorts of mixes.

Industry usually creates pentaethylene glycol monomethyl ether by ring-opening polymerization of ethylene oxide, kicked off by a methyl alcohol starter. Anyone who’s worked with ethylene oxide knows it’s a race between careful engineering and safe handling. The growth of the glycol chain stops once it hits five units, then gets washed and purified by vacuum distillation. This route offers plenty of control—a factory can tweak reaction conditions to target five repeat units reliably. Batch purity came a long way after process engineers pushed for tighter controls on side products and contamination, a shift that also helped lower the odds of having to deal with random unpleasant surprise odors or color.

Beyond acting as a solvent, pentaethylene glycol monomethyl ether plays the role of a soft linker or backbone in organic synthesis. Scientists use the hydroxyl end group for etherification, esterification, or even attaching functional moieties used in drug delivery. For instance, in surfactant synthesis, reacting it with fatty acid chlorides whips up custom-tailored nonionic surfactants. I remember seeing research where its terminal hydroxyl compiled with carboxylic acids to build hydrophilic coatings. The methyl capping group shields one end, blocking polymer extension and giving chemists more control over chain length, which matters a lot in biomedical and coating applications.

Scan a catalog and you’ll see a roster of names: MPEG-5, PEG-5 methyl ether, Methoxy penta(ethylene glycol), and Poly(ethylene oxide) methyl ether 5. Chemists rely on these aliases to track down the right product, especially in large, multinational projects. The CAS number system does most of the heavy lifting in sorting out confusion. Some suppliers, particularly in pharmaceuticals or cosmetics, slap their own codes onto the labels or combine trade names with molecular descriptions. On a more practical level, lab veterans recognize it by viscosity and faint, familiar glycol scent.

Nothing jumps out as hazardous about this ether in casual contact, yet working with gallons of any glycol requires caution. Safety data sheets call for splash goggles, gloves, and decent ventilation. Workers handling heated vessels need to watch for vapors, which can irritate the lungs or eyes if concentrated. Storage stays straightforward: keep it sealed and away from open flames or heat. Environmental releases usually get flagged for cleanup, but small spills wipe up without trouble compared to nasty industrial chemicals. In the years I spent around glycol ethers, I rarely saw serious incidents—most problems cropped up from poor labeling or mixing in old, sticky containers.

Industries made this ether a workhorse in specialty inks, latex paints, textile treatments, electronic cleaning, and even some pharmaceuticals. The mix of water and oil compatibility lets it carry pigments and stabilizers through formulation tanks that clog up on lesser solvents. In paint shops, I saw operators reach for it during changeovers between batches, dissolving stubborn residue so that final products didn’t suffer off-colors. It pops up in laboratory synthesis for PEGylation, where attaching PEG chains extends drug half-life or modulates bioavailability. Its mild toxicity and regulatory acceptance bring it into products like cleaners and beauty serums more readily than many older glycol ethers, which carry stricter workplace exposure limits.

Research circles treat pentaethylene glycol monomethyl ether as both a tool and a subject. Journals fill up with reports on how chain length tweaks alter physical performance in surfactants or drug conjugates. Polymer scientists look for new modifications at the terminal end to improve compatibility with specialty plastics or membranes. Materials chemistry uses its solubility and thermal stability to create thin films and nanostructures. In some university labs, this ether stands as the backbone for new functional soft materials, already miles ahead of solvents with sketchy safety profiles. Getting a handle on these modified glycol ethers means more durable, safer, and effective industrial and healthcare products.

Pentaethylene glycol monomethyl ether, compared to shorter-chain glycol ethers, nudges into a safer bracket based on existing toxicity data. Rats exposed at moderate doses rarely show severe symptoms, though high doses can strain kidneys and livers. Unlike older solvents like ethylene glycol monomethyl ether, which carries reproductive toxicity flags, this larger molecule has cleared many regulatory hurdles for workplace safety and product formulation. Chronic effects and long-term exposure data remain limited, pushing researchers to keep digging, especially as demand rises in consumer goods and medical products. Handling surveys and real-world exposure studies build peace of mind for customers who care about what lingers in their cleaners, coatings, or skin creams.

Looking ahead, demand for reliable, low-toxicity solvents will only ramp up as regulations tighten and consumers ask more questions about what goes into goods. Pentaethylene glycol monomethyl ether finds new applications in electronics, green chemistry, and drug delivery every year. Sustainable production methods, including bio-based ethylene oxide, could draw more companies into offering greener options. Teams continue chasing better data on long-term health and environmental impacts, especially now that its uses span from sealed labs to store shelves. Improving batch purity, especially around trace impurities, means safer final goods where every detail, like skin contact or inhalation, matters. Modern industries lean on this chemical not for nostalgia, but because it outperforms many legacy solvents and leaves fewer headaches for compliance and cleanup.

Pentaethylene Glycol Monomethyl Ether isn’t something you hear about over coffee, but plenty of chemists and manufacturers reach for it every day. This liquid pops up in countless corners of industry, making it an unsung companion to pharmaceuticals, paints, and printed circuit boards. My first experience pouring this stuff into a reactor drum brought lessons I still remember—use the right gloves, trust your nose, and pay attention to its job in a formula. There's rarely a chemical that pulls double duty quite like this one.

Folks who work with coatings lean on this glycol ether to solve problems that stronger, smellier solvents can't handle. It has a knack for dissolving substances that other standard solvents leave behind. I saw industrial cleaners transform stubborn ink and adhesive residues by including just a dash of this ether. Paint makers appreciate its “staying power,” since it controls how fast coatings dry. Too fast, and the finish looks rough; too slow, and work stalls out. Using the right amount keeps brushes gliding and spray guns working without clogging.

Printed circuit boards don’t just spring into existence. Technicians use specialized cleaning fluids to strip away solder flux and grime, and pentaethylene glycol monomethyl ether acts as a trustworthy ingredient in these blends. It cuts through sticky residues without shredding fine copper or delicate traces. Many folks outside the lab never see this step, but any engineer who’s wrestled a sticky circuit board out of a jam can tell stories of solvents that ruined a batch. This ether helps avoid those mistakes by delivering precision cleaning.

Tablet presses and reactors rely on liquids that don’t just mix, but also carry ingredients exactly where they need to go. This glycol ether shines as a solvent in drug development. Labs often face the challenge of dissolving oddball molecules that water or alcohols can’t manage. I once watched a formulation chemist labor over an experimental painkiller—after hours of tinkering, adding this ether pushed the stubborn ingredient into solution. That moment drove home its role in pharmaceutical research.

Whether you're printing a book, a T-shirt, or a barcode sticker, the ink’s ability to stick, dry, and look sharp rests on its recipe. Pentaethylene glycol monomethyl ether brings balance to ink formulations. It keeps pigment particles suspended and ensures they spread evenly. I’ve mixed batches of ink where swapping this ether in made the color pop just right and prevented gumming inside a printer nozzle. Print shops value every minute lost to cleaning failed printheads, and the right solvent blend spares that headache.

This chemical has real staying power because it quietly solves daily headaches in industrial production. It won’t get headlines or star in commercials, but its absence causes real trouble. You see the benefits not because you notice it, but because jobs finish smoothly—cleaner surfaces, sharper prints, and reliable blends.

People in labs and factories often reach for a bottle with a plain label: Pentaethylene Glycol Monomethyl Ether. Maybe it sounds like something buried in a chemistry textbook, but this stuff shows up in places you’d never expect. Its chemical formula—C11H24O6—might look intimidating, but this string of numbers and letters does plenty in the real world. It’s also tied to a single identifier: CAS number 4660-94-6. That’s how anyone—chemist or otherwise—can find information about it in databases or safety sheets without tripping over similar names.

Cleaning out an old storage closet or reading bottles in a paint shop, you might spot this ether on the label. Industry relies on it to thin paints and coatings, wash down sensitive electronics, and tweak chemical recipes until they behave just right. I remember watching a technician in a circuit board plant use a solvent mixture, Pentaethylene Glycol Monomethyl Ether in the blend, to clean sticky residues from polished boards. It did the job fast without stripping away the fine copper lines. Those experiences leave an impression. In the pharmaceutical world, this glycol ether acts as a carrier or solvent for drugs and lab experiments. Because it doesn’t evaporate too quickly or react with every little thing, it gives manufacturers room to work without too many surprises.

So many industries count on reliable raw materials. A hiccup in chemical purity or a mislabeled bottle can set back a week’s production. The clear rules around chemical formulas and CAS numbers help people avoid dangerous mistakes. Mix-ups cause real harm, sometimes leading to contaminated products or even unsafe work conditions. The simple listing of C11H24O6 and CAS 4660-94-6 keeps everyone on the same page. Regulatory bodies, from OSHA to REACH, ask for this level of clarity because it’s not about red tape—it’s about preventing headaches and worse. I’ve seen new hires flustered by long product names, but once they understand the string of numbers and the power of CAS for fast lookups, those records stop being a mystery and start feeling like a safety net.

No one really wants to breathe in chemical vapors, and Pentaethylene Glycol Monomethyl Ether is not immune to scrutiny. It can be irritating in high concentrations, so good ventilation and gloves belong in the picture. Factories have to keep an eye on air quality and worker exposure, or risk falls in both morale and health. Environmental concerns linger too. Ether residues don’t just vanish down the drain. Water treatment plants need information down to the CAS number, so hazardous waste doesn’t sneak past their filters. If a spill happens, cleanup crews check labels as soon as they arrive, scanning for the formula and verifying the CAS. That’s not just bureaucracy—it decides how the response unfolds and which protections matter most.

No chemical comes without trade-offs. Companies ought to keep training updated and safety sheets within arm’s reach, not buried in some folder. New green chemistry initiatives try to replace older solvents with safer, biodegradable options. I hear about research teams testing new blends that drop fewer risks on the environment and the people handling them. That’s not futuristic—some labs already run those trials every week. Raising awareness about the basics, like the formula C11H24O6 and CAS 4660-94-6, isn’t just useful for pros. Teachers, students, and anyone living near an industrial plant all gain from straight talk about what’s really in those bottles and where it travels.

Let’s be honest, safety warnings often feel like background noise. Busy days leave us reaching for products, skipping labels, assuming the routine we know will keep us out of trouble. That works until it doesn’t. I remember cutting corners with household bleach in my twenties, thinking gloves were for the hypochondriacs. That careless attitude ended with a spill that left my skin red for days. Reading up later, I learned just how easily some ingredients can burn right through a top layer of skin or trigger a reaction you never expected.

Some products carry more hazards than others. Solvents, cleaners, fertilizers—each one hides dangers beyond a bad smell. Some irritate eyes or lungs, others slip into the bloodstream just by touching skin. Take a look at the label—words like “caustic” or “flammable” aren’t scares; they’re true. Misuse doesn’t always turn into a trip to the ER, but it builds risk over time. If you have kids, pets, or even forgetful roommates, your mistakes multiply fast.

Gloves, goggles, simple things like keeping a window open—all these get laughed off until symptoms catch up. I’ve heard stories from workers in factories and gardeners in the field. Anyone handling strong chemicals learns to keep a clean set of work clothes, and they never store cleaners near food (or even on the same shelf). The reason is simple: spills happen, fumes drift. You walk off for a minute, and that’s enough for someone else to walk in and get hurt. Washing hands doesn’t sound heroic, but leftover residue can stay on doorknobs, keyboards, or that sandwich thrown together at lunch.

I’ve seen clear plastic bins melted by products they weren’t meant to hold. Some products break down faster in sunlight, others spark with just a little friction. Keep things in original containers, labels facing outward. If the container feels sticky or cracked, transfer the product only if the label survives the move. Fire departments post guidelines for good reason—flammables don’t just ignite on TV. It takes one overheated garage or one forgotten rag for things to get out of control.

Change happens at home and in the workplace bit by bit. One habit at a time. Set reminders to check expired products twice a year. Put up a checklist near where products get stored, highlighting gloves, goggles, and hand washing. If you're leading a team or a household, make it normal to talk about weird smells, spills, or headaches after exposure. Replace “tough it out” with “stop and check.” If curiosity gets the best of you, ask during a visit from a fire marshal, or call a poison control center just to check.

It never feels worth it to stop and suit up for a small chore. But repeated shortcuts become habits. Each step skipped subtracts from peace of mind. I wish I’d learned that earlier, rather than after a mishap. Looking at the bigger picture, following safety rules is less about being afraid and more about being able to do the next task the next day, unharmed. Taking care means your tools last, your spaces stay cleaner, and your family walks away healthy.

I’ve spent years working around industrial labs and warehouses, and anyone who has handled solvents knows—storage matters just as much as safe use. Pentaethylene glycol monomethyl ether might sound like niche chemistry, but I’ve seen it pop up in everything from cleaning solutions to electronics manufacturing. Its behavior isn’t wild or unpredictable, but it deserves respect like any industrial solvent should. Skipping the basics isn’t an option.

What stands out with this compound is its high boiling point and relatively low volatility. That’s a fancy way of saying it doesn’t just evaporate at room temperature or catch fire because the sun hit a drum. But here's the catch: getting too relaxed about storage often leads to accidents or product loss. A chemical doesn’t need to be especially explosive for things to go wrong.

I’ve watched companies cut corners with containers—using old barrels with questionable seals, mixing and matching lids, or worse, grabbing non-chemical-grade plastics from the back of the storeroom. Pentaethylene glycol monomethyl ether deserves sealed, clearly labeled, airtight drums or bottles, made from compatible materials like stainless steel or certain plastics designed for solvents. Corroded metal or unknown plastic can turn a reliable storage solution into a nightmare fast. I remember one instance where a team lost an entire inventory when cheap HDPE started bulging and leaking. Lesson learned.

It’ll stand up to room temperature just fine, but I never trust fluctuating climates. I’ve seen what happens in warehouses that overheat in the summer—cap seals fail, vapor pressure builds, and at best, you lose product. At worst, someone’s exposed to fumes. Cool, covered storage protects not just the chemical, but the people using it. No need to freeze it, just aim for stable, shaded spaces that avoid sunlight and extremes.

This glycol ether doesn’t play nice with water contaminating the drum. Humidity sneaks in, especially if someone leaves a lid cracked. Cross-contamination shows up surprisingly fast—especially if a transfer pump or funnel gets used for two substances in a row. Splash guards, disposable funnels, and strict tool separation aren’t just best practices, they keep your chemical in spec and your operation compliant.

Even though the flashpoint sits at a respectable level and you won’t hear about it blowing up warehouses, vapors can still irritate, and spills create slipping hazards. I’ve been in facilities where workers assumed the “mild stuff” could be handled without gloves or goggles. You absolutely want gloves, goggles, and those simple splash aprons any time you’re dealing with bulk transfer. Don’t let familiarity breed laziness.

Even with perfect organization, lids get knocked over and drums tip. Absorbent spill kits, ventilation readiness, and knowing exactly where safety showers are goes a long way. I always map out where the nearest eyewash station is before opening any drum. A little prep on day one saves a lot of panic down the line.

From tight lids on sturdy drums to clear signage and regular housekeeping, every small habit stacks up. If I could go back and shake my younger self, I’d say: audit your storage regularly, don’t cut corners on containers, and build those habits before an accident forces your hand. Pentaethylene glycol monomethyl ether fits neatly on the shelf—if you treat it with the respect every industrial solvent deserves.

Years working in chemical handling, I saw firsthand how ignoring solvent compatibility causes headaches. Leaks, weird gels, even reactions you don’t want — these remind you that every compound brings quirks. Pentaethylene glycol monomethyl ether, often shortened to PEGMME, steps into labs and factories all over thanks to its reputation as a flexible, unassuming solvent. So, just how friendly is it with the other chemicals it might meet on the job?

PEGMME plays well with water. Chemical structure gives it both the nudge to grab onto water molecules and to loosen up mixes with alcohols like ethanol and isopropanol. I remember it saving a compounding project when the recipe called for dissolving tricky additives — dumping PEGMME in gave faster, clearer blends. Its long ether chain helps it hug water molecules, but still drives in enough flexibility for mixing with polar organics.

It’s easy to lump all glycols together, but PEGMME’s methyl end changes more than just its name. Plugging it into solutions, I saw different separation patterns than its unmethylated cousins. Tossing it with acetone, dimethyl sulfoxide, or even acetonitrile, PEGMME didn’t balk. Chemical data backs this up — strong polarity paired with decent hydrophobic stretch means it bridges the gap between very watery and mid-polar solvents. You won’t find it dissolving everything, but broad reach comes in handy once harsher solvents sit on the no-go list.

I’ve watched batch tanks bubble and spit when someone got too comfortable. PEGMME doesn’t react with most acids or alkalis at typical concentrations, but swinging conditions too far—like strong oxidizers or mineral acids—will chew up its ether links over time. Not quite as stubborn as some short chain glycols, so regular checks matter. Storing it next to aggressive halogenated solvents or strong reducing agents, you risk more than clogging a filter; contamination can sneak in before signs show up.

Any facility using hoses, gaskets, or tanks picks up on swelling and degradation pretty quickly. PEGMME rarely attacks stainless steel, glass, or high-grade plastics like PTFE, based on my field notes. Trouble starts with lower quality rubbers. Polyurethane and some lower-density polyethylene will soften and deform after months soaking in PEGMME. I learned to double-check elastomer choices after a valve gasket gave way, flooding the floor and slowing production for hours.

Looking up chemical compatibility charts helps, but hands-on testing beats paperwork every time. I once saw a supplier sheet shrug off mixing with certain resins, but after a trial run, resin got sticky and hard to control. Pre-mixing small test batches, watching for clouding, odor, or any build-up along container linings keeps surprises at bay. Tuning storage conditions makes a difference — dry, closed tanks slow down degradation, and routine inspections catch warning signs before full-blown failure arrives.

The beauty of PEGMME lies in its adaptability. Pharmaceuticals, paints, even cleaners — different teams find their own sweet spot with concentrations and mixing speeds. It boils down to starting with reliable info, but not betting everything on theory. Just because a glycol ether stands up to most common solvents and doesn’t mess with glassware or pump lines overnight doesn’t mean you can forget it’s there doing real chemical work.

| Names | |

| Preferred IUPAC name | 2-Methoxyethoxyethoxyethoxyethoxyethanol |

| Other names |

PEG-5 Methyl Ether PEG-5 Methylether Pentaethylene glycol methyl ether Methyl Polyethylene Glycol 5 Ether |

| Pronunciation | /ˌpɛn.taɪˌɛθ.ɪˌliːn ɡlaɪˈkɒl ˌmɒn.oʊˈmiː.θəl ˈiː.θər/ |

| Identifiers | |

| CAS Number | 111488-51-0 |

| 3D model (JSmol) | `C(CCOCCOCCOCCOC)OCCOC` |

| Beilstein Reference | 1721251 |

| ChEBI | CHEBI:52598 |

| ChEMBL | CHEMBL526444 |

| ChemSpider | 20902048 |

| DrugBank | DB14036 |

| ECHA InfoCard | 100.124.370 |

| EC Number | “500-240-8” |

| Gmelin Reference | 1242629 |

| KEGG | C19640 |

| MeSH | D053261 |

| PubChem CID | 81635 |

| RTECS number | KN0175000 |

| UNII | WWZCNJNCXX |

| UN number | UN not regulated |

| CompTox Dashboard (EPA) | DTXSID4042920 |

| Properties | |

| Chemical formula | C11H26O6 |

| Molar mass | 238.29 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Odorless |

| Density | 1.082 g/mL at 25 °C |

| Solubility in water | miscible |

| log P | -1.3 |

| Vapor pressure | <0.01 mmHg (20°C) |

| Acidity (pKa) | 14.8 |

| Basicity (pKb) | 6.64 |

| Magnetic susceptibility (χ) | -59.5×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.450 |

| Viscosity | 4.8 cP (25°C) |

| Dipole moment | 2.92 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 225.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -917.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3665.7 kJ/mol |

| Pharmacology | |

| ATC code | C05GX06 |

| Hazards | |

| Main hazards | Causes serious eye irritation. |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes serious eye irritation. |

| Precautionary statements | Keep container tightly closed in a dry and well-ventilated place. |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | Flash point: 143°C |

| Autoignition temperature | 210 °C |

| Lethal dose or concentration | LD50 Oral Rat 5,300 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 6,000 mg/kg |

| NIOSH | SQ3325000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 ppm |

| Related compounds | |

| Related compounds |

Polyethylene glycol Dimethyl ether Methoxy polyethylene glycol Diethylene glycol monomethyl ether Triethylene glycol monomethyl ether Tetraethylene glycol monomethyl ether |