Ethylene glycol monobutyl ether started turning heads back in the early 20th century, tracing its roots to labs working on better solvents for paints and cleaning agents. Old patents from the 1930s and ‘40s show chemical companies hunting for mixtures that would cut grease and disperse pigments. For decades, painters, janitors, and industrial workers poured gallons of this clear liquid into everything from varnishes to surface cleaners. Larger chemical firms ramped up production as the automotive and construction industries boomed post-World War II. The compound never caught the same public attention as acetone, but for those knee-deep in industry catalogs, its arrival meant easier mixing, longer drying times for paints, and stronger degreasing without the harsh sting of older chemicals.

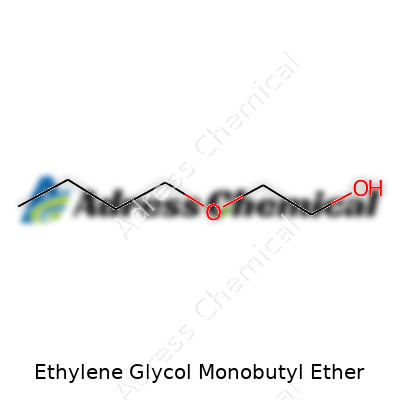

At its core, ethylene glycol monobutyl ether—or simply EGBE to the regulars—shows up as a colorless liquid with a slight, somewhat sweet smell. It dissolves in water, pulling grime out of crevices and stubborn stains from floors. Chemists value its single ether bond and butyl group, as these help bridge the delicate dance between water and oil. This one molecule loosens pigment from resin, folds dirt into cleaning solutions, and keeps products from separating in storage. Whether scrubbing a factory floor, formulating a pesticide spray, or repairing an old car, this solvent’s flexibility stands out.

Pick up a safety data sheet, and the details line up: EGBE has a boiling point just shy of 171°C, a density a touch heavier than water at 0.9 g/cm³, and it slides easily into alcohols and glycols. I’ve watched it blend into water without fuss, making it a reliable carrier in many liquid mixes. It barely registers to the nose at low concentrations, but pour too much and a soft, almost fruity odor lingers. Its moderate vapor pressure means it evaporates more slowly than typical solvents, which makes for better open time in paints and less inhalation risk in a well-ventilated workshop.

Walk down the industrial aisle and you’ll see EGBE shipped in steel drums or polyethylene containers, usually at concentrations around 99%. Labels follow strict hazard codes, showing warning triangles, the CAS number 111-76-2, and flammability symbols. Product sheets must declare purity, moisture content, and residual aldehydes to keep regulators happy. Manufacturers often include safety phrases about protecting eyes and avoiding skin contact, since long-term exposure earns its place on workplace hazard lists. From bulk packaging for manufactories to liter jugs for labs, tracking the batch numbers and lot codes has become routine for compliance.

Making EGBE relies on ethoxylating n-butanol with ethylene oxide under controlled heat and alkaline conditions. Chemical plants set up specialized reactors where butanol combines with ethylene oxide, with the process yielding mostly the monobutyl ether but always a trace of higher glycols. Keeping the temperature right ensures the reaction stays clean, and vacuum distillation helps pull off high-purity product. The leftover bits sometimes head into secondary solvent blends or antifreeze packages, so nothing goes to waste. It takes careful monitoring to balance efficiency, safety, and the minimization of hazardous byproducts.

Reacting EGBE with strong acids leads to its hydrolysis, splitting the molecule and reverting to ethylene glycol and n-butanol. Exposing it to oxidizers can trigger breakdown to acetaldehyde and butyric acid under harsh enough conditions—part of the reason safety protocols ask for separate storage. Laboratories also tweak the structure, swapping the butyl group for other alkyl chains to fine-tune evaporation and solvency properties. Downstream, this flexibility shapes a whole family of glycol ethers known for their utility in coatings and degreasers.

Depending on the region and supplier, EGBE has picked up a few names: Butyl cellosolve still crops up in older manuals, while 2-butoxyethanol and glycol ether EB get equal billing on international labels. Some markets market it under proprietary names, but almost every variant traces to the same molecular structure. Chemical jugglers and safety managers both end up memorizing the synonyms to dodge confusion during audits or while tracing shipment manifests.

EGBE’s benefits come with a few watchouts. In factories, I’ve seen workers use gloves, goggles, and half-mask respirators when handling bulk concentrate, especially during transfer and clean-up. Large chemical users follow OSHA and European REACH guidelines, keeping air concentrations well beneath occupational exposure limits. Spills need containment with absorbent pads and prompt ventilation, since chronic skin contact or heavy inhalation links to blood disorders or liver effects. Training and recordkeeping stay essential, since even seasoned staff can let their guard down around something that looks so much like water.

Paints and surface coatings draw on EGBE’s strength as a coupling agent. Handmade cleaning solutions for home or industry owe their grease-busting power to its solvency, and ink manufacturers rely on it for even pigment dispersion. In textile dyeing, EGBE carries dyes deep into fabrics, delivering lasting color and crisp prints. I’ve seen it used for rust removers, pesticides, and as a carrier for perfumes in industrial air fresheners. Every workshop—or household cleaner under the sink—sits a little cleaner because of chemists figuring out how to turn solvents like this into quiet workhorses.

Today, research teams push for greener chemistries, but EGBE’s balance between price and performance keeps it popular. Scientists study bio-based alternatives and work on limiting emissions from solvents during use and disposal. I’ve read papers exploring new ethoxylation techniques that produce less waste, and pilot plants now recover EGBE vapor to cut down on loss during manufacturing. Still, any substitute must offer the same edge for dissolving both polar and non-polar gunk, a feat EGBE manages well.

Early toxicity studies on animals flagged concerns over blood and organ effects at high doses, prompting tighter regulations and stricter labeling. More recent research looks at workplace monitoring, tracking workers exposed over years to gauge chronic effects. Long-term data shows increased vigilance pays off: wearing protection and following exposure guidelines drops the risk of adverse health effects. Some studies link EGBE to reproductive issues, which keeps pressure on manufacturers to update safety protocols, ventilation systems, and medical surveillance for employees.

With regulations getting tighter in Europe, North America, and parts of Asia, EGBE’s days as a go-to solvent face mounting pressure. Companies hunt for bio-based alternatives and solvents with lower health risks, but many find EGBE hard to replace in tough applications. Industries look at recycling and vapor recovery to reduce environmental release, while regulatory agencies push for periodic reviews of exposure limits. As paint and cleaning product manufacturers rethink formulations, the future likely holds more hybrid blends, tighter safety rules, and ongoing research into safer drop-in replacements that still perform under real-world conditions.

Ethylene Glycol Monobutyl Ether, or butyl cellosolve as some call it, doesn’t jump out as a household term. Still, the things we take for granted often owe a lot to it. This solvent isn’t tucked away in a research shelf; it shows up in places like your garage, your toolbox, the office cleaning closet, and even in paints splashed across homes and offices.

Walk down the cleaning aisle, and many bottles hold a secret this chemical helps unlock: oily grime and tough smudges wipe away a lot easier. Professional cleaners trust it in glass sprays, floor scrubs, and degreasers. I’ve seen old car grease slide off work boots in shops where this solvent does the heavy lifting. It breaks up oily spots on shop floors and kitchen counters where plain water just can’t compete. People working in janitorial jobs, like my cousin, swear by products using this chemical; it cuts through kitchen grease without much elbow grease.

Paints never seem to dry right without a little help from solvents. House painters and DIY weekend warriors alike see fewer streaks and better coverage. This solvent helps paint flow out smoothly and hang onto walls, doors, and trim. Manufacturers add it to water-based paints to help blend ingredients and stop paint from drying too fast. That smoother finish on your living room wall owes much to it. In my own home, the difference between a cheap paint that drags and cracks, and a premium one that glides on buttery-smooth, often comes down to the mix inside—usually including this key ingredient.

Printing shops rely on solvent-based inks to produce clean, crisp graphics whether on newspapers, packaging, or glossy flyers. Ethylene Glycol Monobutyl Ether helps ink stay at the right consistency, so printheads won’t clog and designs hold sharp edges. Friends of mine at a local sign company complain anytime a batch shows streaking or fading; often, that points to changes in the ink blend, and this substance comes up in those conversations a lot.

Factories turn to this chemical in heavy-duty degreasers and rust removers. Cleaning old machinery, stripping away tough grime, and getting parts prepped for painting or coating often means rolling up your sleeves, grabbing a blend that includes it, and scrubbing. Every mechanic I know wants tools and parts oil-free if they’re going to weld, glue, or paint. This solvent helps cut down job time and reduce frustration.

With all these jobs, it’s easy to forget there’s more to this stuff than cleaning and coating. It carries risks if you breathe it in or let it touch your skin too long. Wearing gloves, opening a window, and following label advice seems like basic sense, but lots of folks skip these steps. Companies can help by making training routine and making personal protective equipment easy to grab.

We all get used to seeing supplies on the shelf and don’t often think about what brings those products to life. Still, a look at Ethylene Glycol Monobutyl Ether shows how much work goes into the simple things—clear windows, fresh paint, clean machinery. Sometimes, it’s these behind-the-scenes helpers that keep modern life humming.

Every time I’ve reached for a drum of ethylene glycol monobutyl ether in a shop or research lab, the seriousness of what I’m handling sinks in fast. This solvent, often called 2-butoxyethanol, soaks up grease and grime better than water and has a way of seeping into the skin almost as easily. You might find it in glass cleaners, paints, or degreasers, tucked behind a long chemical name on a label. Knowing its risks means you start thinking harder before your hands ever reach the lid.

Skip the lab coat and gloves for only a few minutes and the risks creep in. Ethylene glycol monobutyl ether evaporates quietly, hovering in the air whenever you splash it. A gust of wind or busy day can send fumes straight to your lungs. You don’t need to feel queasy or dizzy to know there’s a problem. Based on OSHA charts and the CDC’s data sheets, this stuff can hurt your blood, kidneys, or liver through long or repeated exposure—even before it irritates your skin or eyes.

I remember handling an industrial degreaser for the first time and thinking a pair of thin latex gloves would cut it. That job taught me the hard way. The right gear starts with chemical-resistant gloves, long sleeves, sturdy goggles, and a face shield if there’s a risk of splashes. Ventilation matters as much as anything else. If a shop’s exhaust fans sound like they’re flagging, crack a window and pull in a portable fume extractor. Sometimes, a simple mask won’t keep vapors out, and an organic vapor respirator becomes the only real line of defense.

It’s surprising how slippery things get when there’s a spill. Some folks grab old towels or mops, but spreading the chemical around isn’t cleaning—it's spreading danger. I learned to keep absorbent spill kits close, tossing the materials into a sealed drum once the mess is under control. Clearly mark the area if there’s a chance someone else could traipse through. Nothing slows a workday like an accidental chemical burn when the cleanup box sits unused in the corner.

Reading the safety data sheets sounds tedious. Still, knowing whether a chemical can burn your lungs or ruin your favorite jacket beats reading about it in a hospital brochure later. Clear labeling on every jug—names, warnings, hotlines—cuts out the guesswork. I’ve seen workers grab unlabeled bottles and take unnecessary risks because nobody took five minutes to write a word on the tape.

Park those containers in a cool, dry shelf, away from sunlight, sparks, or heat. I always keep incompatible chemicals separated; that habit is based on a mistake that left scorch marks on a bench. Locks on cabinets or storage rooms stop curious hands or accidental spills before they start. Keep an eye on shelf life too, since forgotten bottles can cause trouble years later.

If any splashes hit my skin, I move fast, rinsing with water for several minutes before looking for more help. An eyewash station close by should never gather dust. Quick action cuts down pain and damage, but you only remember that if you’ve practiced the drill before. Training means you won’t freeze up or fumble the important details with a burning hand or stinging eye.

Caring about chemical safety is really about watching each other’s backs. A regular talk about protocols, stocking gloves and goggles, and sharing stories of close calls has always kept our crew safer. If everyone understands the risk and respects the process, ethylene glycol monobutyl ether becomes another tool, not a looming danger.

Ethylene Glycol Monobutyl Ether, better known as 2-butoxyethanol, turns up in a surprising number of places. You catch it in window cleaners, some paints, and plenty of degreasers. It helps dissolve oils and makes cleaning products work faster and look clearer. Over the years, most people don’t even realize they’ve used it, but this chemical isn’t just a behind-the-scenes helper. It can cross paths with skin or end up as vapor in the air, bringing up important questions about safety.

A lot of families and workers who spend hours cleaning probably never hear stories about chemical exposure until someone starts coughing or gets a headache. These moments deserve more attention. There’s research showing that 2-butoxyethanol can irritate eyes, nose, and throat. Skin contact sometimes leads to rashes or peeling. Breathing in high amounts drives up the risk of headaches and nausea. Even though the scent might not seem strong, it’s too easy to forget about what lingers in the air after scrubbing down a kitchen counter or spraying windows.

Occupational exposure raises the stakes. Many factory workers use products with 2-butoxyethanol daily. Over time, high levels can bother the blood, kidneys, and liver. Some lab studies in animals even hinted at red blood cell damage. Health authorities, including the CDC and EPA, list it as a hazardous material, but they stop short of calling it a clear-cut cancer risk for people. That uncertainty creates a gray area—enough of a concern that people in cleaning and manufacturing jobs worry if their gear actually keeps them safe.

Plenty of households try to stick to safer products these days, and with good reason. Once, after using a strong degreaser in a poorly-ventilated garage, I found myself with watery eyes and a scratchy throat for hours. That experience drove home how easily fumes build up. Even though labels warn users to keep spaces aired out, those warnings go unnoticed when you’re rushing to finish a chore. A lot of us trust that if something sits on a hardware store shelf, it must pass some basic safety checks. The truth: regulations don’t always mean zero risk.

Changing work routines offers the most immediate step forward. Employers should offer training on chemical safety, not just a pamphlet with tiny print. Workers need sturdy gloves and proper masks, not just thin latex and flimsy dust covers. Air flow at job sites should get as much attention as deadlines. For families, the best plan starts with switching to cleaning products that avoid solvents like 2-butoxyethanol. Look for plain soap or vinegar blends, which tackle grease with much less drama.

More transparency from manufacturers would help a lot. Detailed lists of ingredients—ones you don’t need a chemistry degree to read—give everyone a chance to dodge unwanted exposure. At home and at work, small changes add up to fewer headaches, less coughing, and peace of mind that lingers after the shine fades from the cleaned windows.

Moving barrels and drums became second nature after enough years spent around shipping docks and factory floors. I came across some mean stuff in all that time, and Ethylene Glycol Monobutyl Ether—often known as Butyl Cellosolve—ranks high on the list. Many folks in cleaning products or paint know this chemical and what it can do. Slip up, skip a detail, and someone might get hurt, or the company takes a costly hit.

Out in the real world, the worst problems start with lazy shortcuts: drums left loose near loading ramps, missing hazard labels, or broken pallets. Material like this isn’t as forgiving as table salt or walking flour. It eats at plastic if you use the wrong container. It creates dangerous fumes, especially inside buildings with lousy air systems.

My friend Dean learned this the hard way, backing a pallet jack through a poorly marked corner where two drums were stacked too close. One drum toppled, leaking a slippery mess. He needed new boots and a week’s worth of clean-up, and it drove home one lesson: always check that containers hold up to aggressive chemicals, and always keep proper distance.

Factory lofts tend to heat up mid-summer. I’ve watched barrels sweating under high humidity, which means more vapors building up. This stuff isn’t water; those fumes can irritate your eyes or worse. Without decent airflow, you start seeing headaches, strong odors, and questions from neighbors.

Keeping material cool cuts that risk. I’ve seen companies set barrels near outside walls to catch breezes or fire up fans. Maintaining a solid roof and no sunlight saves hassle too—ultraviolet light speeds up container breakdown. A leaking drum never means a minor fix.

Poor labeling frustrates the next crew even more than bad storage. Picture hunting for the right chemical during a busy night shift, scrambling to double-check paperwork because the label wore off. Regulations might demand it, but folks in the field appreciate it most: clear chemical names, hazard warnings, and date of arrival marked in bold.

Shipping this solvent pushes pressure up another notch. Forgetting to strap the drums means risking spills on a bumpy road. Too many times, I've seen workers skip leak checks. It only takes one weak seal to soak floorboards or damage cargo nearby.

Most fleet drivers want details: "Is this container tight? Did you double-wrench the bung? Are my documents ready if someone stops me?" Regulations about hazardous chemicals don’t come from nowhere; spilled solvent can earn monster fines, not to mention hurt people at rest stops or warehouses down the route. Old-timers always said: "Check each drum by hand, and never trust the last person’s seal."

A safe setup starts with the right drum—steel for strength, lined if needed. Keep them off concrete, which can trap fumes and wick up spills. Pallets in good shape save time and protect warehouse floors. Heavy stuff like this belongs far from breakrooms, escape routes, and food storage. If you notice a weird smell or see mist in the air, slow down and fix it.

Checklists on the wall make everything easier, covering vent fan status, drum conditions, and the right gear within arm’s reach. Most accidents I’ve seen came from slipping past one simple step or brushing off someone’s concern as over-cautious.

Experience outpaces theory. A team that respects the risk, keeps equipment like goggles and gloves close, and looks out for one another builds the safest system. It’s not about abstract rules—just a tight work culture, clear eyes, and decency for the next person rolling by.

Walk into any hardware store with a paint section, and chances are, you’re probably not thinking about the lineup of chemical names hidden in those cans. Ethylene glycol monobutyl ether, known on labels as 2-butoxyethanol or EGBE, shows up everywhere. It’s not just a fancy solvent for lab techs—people use it to get a job done, whether for cleaning, degreasing, or making paint spread smoother on a wall.

Open a bottle of EGBE, and you’re met with a faint but sharp odor, something sitting between sweet and slightly off-putting. It looks like water—colorless and just as runny, but there’s no confusing the two after a sniff. It mixes with water and most organic liquids without complaining, which sounds boring at first, but this actually makes life easier. Janitors, painters, and mechanics want a solvent that slips into mixtures and does not separate or turn cloudy.

The flash point floats around 60 degrees Celsius. Set a rag soaked with EGBE near an open flame and you’ll see this property quickly in action. It also boils at 171°C, so it sticks around longer than acetone or alcohols under heat—a handy trait for stripping paint or cleaning engines where you don’t want your cleaner evaporating too fast. At room temperature, EGBE sits comfortably as a liquid through most seasons in most places.

There’s real strength in EGBE’s chemical structure, a split personality of sorts—the ether group on one end, and a chunk of alcohol on the other. This combo lets it break down greasy messes and tackle both water-based and oil-based stains. Walk through a factory floor and you’ll see this chemical put to work where it can plow through stubborn residues that water just can’t touch alone.

Mixing with acids or harsh oxidizers turns EGBE into something much less friendly. In the wrong hands, or mixed without care, this chemical can pump out dangerous fumes or react in a nasty way. It’s not just a theoretical risk. Poorly ventilated workshops can fill up with vapors, especially in summer, and these hang in the air longer than folks sometimes realize. According to the National Institute for Occupational Safety and Health, breathing too much EGBE vapor can irritate noses and eyes, and even put a real strain on workers’ health after long-term exposure.

Big industries count on EGBE for cleaning and manufacturing, but nobody wants solvents on the loose in the air or water supply. Many work sites now set up exhaust fans and issue respirators. Some companies have shifted toward products that break down faster and aren’t as tough on people’s lungs. Others have swapped in new solvents that pull off the same cleaning tricks with less risk.

Having handled solvents in a high school chemistry classroom, I’ve seen firsthand how tempting it is to use a little too much muscle on a sticky beaker. It’s a reminder to pay attention to both the chemical’s strengths and its downsides. For all its grease-busting qualities, EGBE belongs on the list of substances you treat with respect. Gloves, goggles, and a steady hand keep jobs safe, whether you’re stripping paint or cleaning an engine block.

In the end, the best approach often comes down to balancing performance with safety—choosing when to use EGBE’s powerful bite and knowing when a gentler approach can get the job done just as well.

| Names | |

| Preferred IUPAC name | 2-Butoxyethan-1-ol |

| Other names |

2-Butoxyethanol Butyl cellosolve Butyl glycol Ethylene glycol butyl ether Glycol ether EB EGBE |

| Pronunciation | /ˌɛθ.ɪˌliːn ˈɡlaɪ.kɒl ˌmɒn.oʊˈbjuː.tɪl ˈiː.θər/ |

| Identifiers | |

| CAS Number | 111-76-2 |

| Beilstein Reference | 3444360 |

| ChEBI | CHEBI:31797 |

| ChEMBL | CHEMBL1359 |

| ChemSpider | 6760 |

| DrugBank | DB00783 |

| ECHA InfoCard | 03-2119457550-43-0000 |

| EC Number | 203-905-0 |

| Gmelin Reference | 70216 |

| KEGG | C06501 |

| MeSH | D005006 |

| PubChem CID | 8030 |

| RTECS number | KL8575000 |

| UNII | YMR8B5QG8T |

| UN number | UN2810 |

| CompTox Dashboard (EPA) | DTXSID9020718 |

| Properties | |

| Chemical formula | C6H14O2 |

| Molar mass | 118.18 g/mol |

| Appearance | Clear, colorless liquid with a mild, ether-like odor |

| Odor | Mild, sweet |

| Density | 0.900 g/cm³ |

| Solubility in water | Miscible |

| log P | 0.83 |

| Vapor pressure | 0.6 mmHg (20°C) |

| Acidity (pKa) | 14.7 |

| Basicity (pKb) | 1.07 |

| Magnetic susceptibility (χ) | '-52.0 x 10^-6 cm³/mol' |

| Refractive index (nD) | 1.419 |

| Viscosity | Viscosity: 3.3 mPa·s (at 20 °C) |

| Dipole moment | 2.22 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 309.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -481.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3228 kJ/mol |

| Pharmacology | |

| ATC code | D07AX |

| Hazards | |

| GHS labelling | Warning, H302, H312, H315, H319 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H312, H315, H319 |

| Precautionary statements | P210, P280, P301+P312, P305+P351+P338, P337+P313 |

| Flash point | 60°C |

| Autoignition temperature | 230 °C (446 °F) |

| Explosive limits | 1.1% - 10.6% |

| Lethal dose or concentration | LD50 (oral, rat): 1480 mg/kg |

| LD50 (median dose) | LD50 (median dose): 470 mg/kg (rat, oral) |

| NIOSH | NIOSH: K2 |

| PEL (Permissible) | PEL: 50 ppm |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | 700 ppm |

| Related compounds | |

| Related compounds |

Ethylene glycol Diethylene glycol Ethylene glycol monoethyl ether Ethylene glycol monopropyl ether Propylene glycol monobutyl ether |