Many chemicals carry a long backstory, and Ethylene Glycol Diethyl Ether, sometimes called Diethyl Cellosolve or EGDE, started making ripples in chemistry circles in the first half of the twentieth century. During an era packed with lab glassware and smoky benchtops, solvents like this one emerged alongside the rapid rise of industrial chemistry. Folks weren’t just looking for another way to thin paint or dissolve a stain; they wanted new tools to help shape plastics, extract flavors, and drive the engines of medicine. With its roots tied into the growing organics industry, Diethyl Cellosolve grew up beside modern polymers and the demand for specialized processing agents.

EGDE steps out as a clear, nearly colorless liquid that escapes attention at first glance. Yet dig into its resume and you’ll find this ether cropping up in dozens of labs and workshops. Companies buy it in drums, chemists pour it in graduated cylinders, and manufacturing outfits use it as a workhorse for extraction, cleaning, and synthesis. This stuff doesn’t just sit on a shelf; it fills a set of roles—from solvent to reactant—that keep production lines and research moving.

On the bench, Diethyl Cellosolve pours smoothly, bringing a faint, almost sweet smell. With a boiling point hovering around 165°C and a melting point under -100°C, it sticks close to its liquid form through a range of temperatures. Its density clocks in at roughly 0.87 g/cm³, which keeps it lighter than water but heavy enough to pour with substance. It mixes easily with many common organic solvents—alcohols, ethers, esters—while resisting easy dissolution in water. I’ve seen folks use it for who need both volatility and a measured evaporation rate, and that sweet spot often steers projects its way.

Ordering a drum of EGDE doesn’t mean much unless you know the grade and purity. Chemical suppliers put out product sheets showing purity levels commonly around 98% or better. Telltale impurities, like residual water or traces of starting ethylene glycol, get stamped right into the batch analysis. Labels on containers show hazard information—a flammable label and a warning about inhalation risks, for example—and storage requirements. In my experience, folks who ignore label specs risk more than an angry safety officer: a little negligence could mean spoiled product or worse, a sticky cleanup job.

The go-to industrial path for making Diethyl Cellosolve usually starts with ethylene oxide and ethanol. The reaction runs under controlled pressure, with a catalyst guiding the transformation to make sure no pesky byproducts pile up. The setup calls for carefully monitored temperatures—too hot and side products bloom, too cool and conversion lags. Once it’s made, distillation steps in to clear out leftovers, leaving the finished ether ready to get bottled. On the bench scale, I’ve watched synthesis efforts hinge on timing and temperature more than any high-flown theoretical chemistry; practicality wins in the end.

As a solvent, EGDE sees more action as a medium than as a player, but its structure lets it get involved in more adventurous organic reactions. It works well as a medium for Grignard reactions and alkylations, sometimes even acting as a reagent in cases where ethereal oxygen can step in. Chemists can modify it further, adding substitutions on the ethyl groups or even using it as a starting block for polymers. In many cases, it outperforms other solvents in selectivity or reaction speed, turning complicated syntheses into almost routine steps in the right hands. Seeing an experienced chemist guide a tricky reaction using this ether shows how familiar folks get with its quirks and advantages.

If you check supplier catalogs, this ether goes by several names: Ethylene Glycol Diethyl Ether, Diethyl Cellosolve, and 2,2'-Oxybis(diethylether). You’ll bump into older trade labels, sometimes just “Cellosolve Ether” tacked onto a supplier SKU. For anyone ordering or searching literature, it always pays to glance through a list of synonyms so nothing gets lost in translation. Mismatched names have seasoned chemists digging through shelves for hours, and it’s a problem that spans languages and brands alike.

From a safety standpoint, EGDE isn’t a chemical to toss around carelessly. It flashes at around 50°C, so one loose heating mantle or a spark could end a shift prematurely. Labs need tight ventilation since the vapors irritate eyes and lungs—standard fume hoods and splash goggles aren’t just bureaucratic theater, they really keep folks from winding up at the clinic. Long exposure at even moderate levels leads to headaches and nausea, and cases of chronic misuse can run deeper. Proper gloves—nitrile or neoprene—and quick-clean spill protocols stay close at hand on any good lab bench. The folks who work with EGDE daily always say that respecting the MSDS is the only way to stay healthy in this line of work.

Ethylene Glycol Diethyl Ether finds steady work in industries ranging from pharmaceuticals to coatings. In paint and varnish shops, its medium evaporation rate gives finishes a smooth, professional touch without streaks or bubbles. Labs lean on it as a reliable carrier for reactions needing both polar and non-polar environments. Extraction processes, especially those drawing flavors or fragrances from botanicals, turn to this ether for its unique ability to dissolve a spectrum of compounds. I once watched a flavorist tackle a stubborn extraction problem with EGDE when nothing else cut through the mixture—sometimes, it’s the only answer.

The search for better solvents and reaction media always runs through EGDE’s territory. Over the years, research labs have run experiments looking for greener, less toxic alternatives, but Diethyl Cellosolve hangs on thanks to its balance of volatility and solvency. In polymer chemistry, where consistency and reproducibility make or break a material, this ether’s reliability keeps it in high demand. I’ve watched teams experiment with substitutes, only to circle back after comparative tests. Research groups focusing on pharmaceuticals develop new drug synthesis protocols around this solvent for certain sensitive reactions, knocking hours off purification steps. Teams who embrace it early tend to stick with it, arguing that its quirks become strengths with a bit of practice.

Like many ethers, EGDE raises flags about workplace safety and public health. Toxicology studies have mapped out its acute effects—inhalation, skin absorption, even chronic low levels all leave a trail in health data. Research in animals showed impacts on liver and kidney function with repeated exposure, which convinced regulators to draw sharp lines on permissible exposure limits. Occupational health teams focus on air monitoring and personal protection as the front line. Even so, I’ve met folks who underestimate risk, and every accident or near miss reminds the community that no chemical stays safe without respect and vigilance. Some university labs now push for alternatives, but the calls for strict monitoring still ring out in most safety meetings.

Looking ahead, EGDE’s role won’t fade easily. With stricter environmental and workplace regulations on the horizon, research is pushing for safer, bio-based solvents, but transitional periods like these rarely move at the pace of dreams. This ether remains a favorite for specialized industrial syntheses, niche flavor work, and some medical preparations. I expect more targeted research into modifying its structure or finding drop-in substitutes able to match its performance with less hazard. Industry veterans tell me advances will keep chipping away at its dominance, but the chemical’s unique combination of properties means it will stick around, at least for the short and medium term in the areas where nothing else quite fits the bill.

Ethylene glycol diethyl ether doesn’t roll off the tongue easily and people probably don’t pause at hardware stores wondering about its story. But for chemists, product manufacturers, and plenty who never see the inside of a lab, this small liquid has quietly kept factories and processes running. Sitting in brown glass bottles or fed into reactors, this compound’s skill lies in being an efficient, versatile solvent – and industrial workers know a good solvent can save both time and trouble.

Production floors need stuff that can clean up after other substances and mix things that wouldn’t normally come together. Ethylene glycol diethyl ether fits that bill, especially for industries such as paints, varnishes, inks, and dyes. People who spend their days at paint factories know how critical it is to get colors to mix fast and thoroughly, whether they’re working on vehicle finishes or vibrant art supplies. This solvent helps keep components dissolved and prevents clumping or streaking. When inks need to spread evenly or dyes must sink into fabrics without patchiness, it’s this chemical that quietly does the heavy lifting in the background.

In electronics, printed circuit boards are the backbone. Cleaning them without damaging delicate parts calls for a solvent that cuts through residue and grease without lingering. Ethylene glycol diethyl ether steps into this role. From personal experience working on small repair projects, I’ve learned that regular cleaning alcohol doesn’t touch stubborn flux or adhesive residues, but a small amount of the right ether can send the gunk packing and prepare the boards for finishing touches.

People don’t always appreciate the messes that chemical syntheses can make: sticky mats, residues clinging to glass, or stubborn mixtures stuck to the side of flasks. Ethylene glycol diethyl ether brings reliability in dissolving polar and nonpolar compounds, which makes it useful for extractions, purifications, and reactions that need both water-mixing ability and a bit more punch than regular alcohols.

Its low boiling point means it flashes off quickly, which helps speed up drying and leaves behind less residue than heavier solvents. Researchers mixing up specialty coatings, pharmaceuticals, or polymers in pilot labs call on this feature to streamline their workflow and cut down on wait times. In college labs, budgets always ran tight. Efficient solvents let us recycle glassware faster and avoid running short on containers, which made days less stressful for everyone.

No one who spends enough time in production fields takes chemical safety lightly, and that includes ethylene glycol diethyl ether. It evaporates quickly, which sounds helpful until someone in a poorly ventilated room starts feeling dizzy or sick. People with experience know to gear up with gloves and goggles, keep a fume hood running, and avoid spilling it on skin. Regulations keep tightening, which sometimes leads to supply headaches, but the biggest risk comes from cutting corners on safety–not the ingredient itself.

In a world where sustainable and safer alternatives get more attention, finding greener chemicals always sits on the horizon. Some manufacturers now look for solvents that break down easily or carry lower toxicity but end up giving up the efficiency and reliability of old standbys like ethylene glycol diethyl ether. Maybe the real solution is supporting better safety training, stronger workplace protections, and more research into safer replacements, instead of quick bans with no strong alternatives. The workhorse solvents aren’t going away overnight. For now, smart use and respect for the risks keep the gears turning.

Anyone who’s spent time in a lab knows the potential headaches that can come with working around chemicals like Ethylene Glycol Diethyl Ether. This clear, sweet-smelling liquid often hides its danger pretty well, which sometimes fools folks into thinking it’s not a big deal. My first real lesson with solvents taught me never to drop my guard. This one packs both health and fire risks that demand respect.

Most will agree, eyes and skin ask for the most protection. Splashing this ether anywhere near your face can lead to serious burns and irritation—sometimes worse if you end up rubbing your eyes. Simple safety goggles or even a face shield keeps a bad day from turning into an ER visit. Gloves matter just as much. Nitrile holds up much better than old latex pairs, especially during long tasks. I remember once helping a colleague clean a minor spill, and his hands itched for hours afterward because he grabbed the closest gloves around rather than checking the label.

Nobody wants to breathe in chemical fumes all day either. This solvent gives off vapors that can mess with memory, judgment, and even breathing if the room isn’t set up right. Many labs stick with hoods—for good reason. Any setup that lets those vapors drift through your workspace just increases the odds of headaches and mistakes. At my last lab, we kept a simple rule: if you’re pouring or heating, keep it under an exhaust hood, no exceptions.

Fire worries come straight to mind with Ethylene Glycol Diethyl Ether. The liquid itself lights up faster than gasoline, and vapors can travel, looking for an open flame or even a hot surface. This solvent once took out part of a storage cabinet in my early research days. We had kept it too close to a heating element, and one careless moment was all it took. It doesn’t take long to understand the value of proper flammable storage. Metal safety cabinets earn their keep, especially when used with chemical-resistant bins and easy-to-read labels.

Static sparks can seem harmless until they aren’t. Many labs use special mats or ground wires when transferring larger amounts to dodge those dangerous sparks. Folks sometimes scoff at these little details until they watch a nasty flashover from one missed step.

Most people end up dealing with spills at some point. Cleaning up with paper towels just spreads the danger around. Always better to blot up with proper absorbents and store the waste in steel or HDPE containers—no glass if you can help it. I’ve seen glass break during disposal and turn a small problem into a full-on mess. Marking those containers with the full chemical name—no sloppy handwriting—cuts down on confusion later. Nobody wants to guess what’s inside a half-used jug.

All the rules in the world won’t help without a crew that actually cares about following them. Training has to move past reading a binder or watching a video. Mentoring new lab workers through hands-on practice makes safety automatic. I still remember my supervisor nudging me away from bad habits, like skipping allergy gloves because I ‘just needed a second.’ Over time, it becomes second nature to check for goggles, put on the right gloves, and double-check ventilation. It’s the small things done every day that keep big accidents from happening.

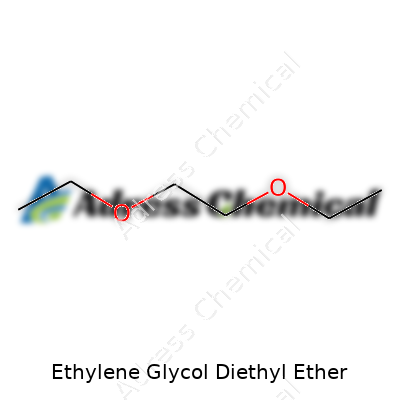

People trust everyday chemicals to just do their job without giving much thought to what’s inside the bottle. I’ve spent enough time in labs to know that a simple name can hide a surprising complexity. Ethylene glycol diethyl ether carries a mouthful of a name, but it plays a clear role across labs and industry. If you crack open a chemistry catalog, you’ll see its formula: C6H14O2. The structure? Picture oxygen atoms serving as bridges between carbon chains—the core of many solvents we rely on.

I’ve drawn this molecule countless times in dusty notebooks. Ethylene glycol diethyl ether looks like this: the glycol part comes from ethylene glycol, which means two carbon atoms linked by an oxygen bridge, with another oxygen anchoring the terminal groups. Swap out the hydrogen atoms on the glycol for ethyl groups, and you get two chains of CH2CH3 dangling from either side of that oxygen spine. If you lay it out: CH3CH2OCH2CH2OCH2CH3. Each ethyl group gives the molecule flexibility, a boost to its liquid properties, and a knack for dissolving substances that escape most alcohols or plain water.

From first-hand experience, lab work with glycols can turn messy. The placement of those oxygen atoms, along with the carbon chains, makes this ether nonreactive enough to avoid headaches but polar enough to dissolve the trickiest organic compounds. The two diethyl ether groups break the usual rules found in simple glycols: they block water from tugging on the molecule, letting this solvent excel where others fail.

A good scientist adapts. I’ve switched from regular diethyl ether to ethylene glycol diethyl ether when reaction purity drops or certain chemicals refuse to budge. Its chemical backbone gives it lower volatility—no clouds of flammable vapor drifting around, which means safer working conditions. Those molecular tweaks aren’t just a classroom curiosity. They shape how chemists store, handle, and dispose of chemicals, and keep accidents from turning into disasters.

Labs usually push for solvents that clean up without drama. Ethylene glycol diethyl ether leaves fewer residues after evaporation, outshines many alternatives in high-boiling applications, and stays friendlier with sensitive compounds. I’ve used it in cases where delicate organics might break down under harsher conditions. The slightly higher boiling point lowers some stress about inhaling too much, too fast.

Safety training treats all ethers with suspicion, and for good reason. Even though this one skirts around lots of the volatility and peroxides shared by regular diethyl ether, storage in dark, airtight containers, away from oxidizing agents, remains standard practice in every well-run lab I’ve worked in. Small changes in a molecule’s layout change everything, including the way you shelve it in the flammable cabinet.

Solving problems starts with understanding what’s in your flask. Designing safer solvents, picking the right chemical for each job, and keeping hazards low comes down to knowing both formula and structure. Ethylene glycol diethyl ether isn’t just a line in a textbook. Whether a student is figuring out solubility, or a chemical engineer is choosing what to pump into a reactor, real-world safety hangs on the details of molecules like this.

Ethylene Glycol Diethyl Ether goes by plenty of names, but none of them sound friendly if you spill it or breathe too much of it. I’ve spent enough hours in labs to know what sloppy storage can do. Forgetting about careful handling can easily end with headaches, ruined experiments, or phone calls to safety officers. In almost every chemistry storeroom I’ve seen, bottles of ethers have their own little corner, guarded with more caution than any flask of sugar or salt.

Some people hear “flammable” and imagine gasoline. This ether can catch fire from a spark or even just a stretch of warm sunlight coming through a window. Putting it next to heat sources or stacks of oxidizers spells out trouble. I remember a colleague once left a partly used ether bottle on a bench, and after a week, we could smell it from the hallway. Luckily, nothing worse happened, but the lesson never left me. Temperature and dryness matter. A cool, dark spot beats any shelf in plain view. No one wants to grab a warm glass bottle that could start leaking vapor just because it sat too close to a radiator.

Original containers do more than carry labels and instructions. Factories seal these ethers in glass, tightly capped to keep out air. Something small, like a cracked cap or a loose seal after pouring, messes everything up. These bottles never make friends with plastic or old jars lying around the shop. Bad containers let in moisture and air, feeding peroxide formation, which is hardly a household word until you see what peroxides from ethers can do. I knew a technician who had to evacuate a storeroom because of cloudy crystals at a bottle’s rim.

The best labs have storage cabinets designed for flammable chemicals, with vents that prevent vapor build-up. Strong ventilation and prominent hazard signs keep everyone alert. In my old department, people grumbled about “all those warning stickers,” but nobody wanted to test life without them. Everyone, from interns to veterans, learned to spot those yellow and red markings at once.

Nobody likes paperwork, but documenting storage locations and inspection dates keeps surprises away. I used to log chemical inspections every Friday and, more often than not, we’d spot caps needing tightening or shelves needing a cleanup. If a bottle looked older than last summer, we’d test for peroxides before touching it. Simple peroxide test strips saved more than a few people from nasty blasts. If the ether aged out or changed color, it went straight into hazardous waste, no arguments.

Talking about chemical safety can sound dramatic, but the quiet routines of good storage save lives and money. For this chemical, that means avoiding light, heat, and air, storing bottles in ventilated cabinets, and never leaving them forgotten in a corner. Training counts. Too many accidents trace back to someone not getting a briefing or assuming that ethers “aren’t that bad.” In my time, short conversations and clear rules stopped nearly every near-miss before it became a headline.

I’ve spent more time in chemistry labs than I care to admit. There’s a special frustration that comes from watching two liquids turn cloudy right in front of you, especially when your day depends on a clear solution. Ethylene glycol diethyl ether, or EGDE for short, is one of those solvents that gets people talking: can you mix it with water or other common solvents without trouble? It’s not just a lab curiosity—it affects how chemists design experiments and how industry folks manage production.

If you pour EGDE into water, they mix smoothly without resistance. That’s not trivial. Substances like diethyl ether won’t blend with water at all—the layers will stubbornly separate every time. EGDE owes its willingness to mix mainly to the glycol group holding onto the ether backbone, introducing a balance between organic and polar structures. Chemists call this behavior “miscibility.” No weird layers, no awkward emulsions; just a neat, uniform liquid. This makes life easier during extractions, cleaning routines, and when you want to avoid phase separation headaches.

EGDE isn’t picky. It lines up pretty well with a broad cast of solvents—alcohols, acetone, chloroform, and the usual suspects like ether and benzene. If you’re running reactions or cleaning up samples, this flexibility lets you ditch heavy-duty controls or complex mixtures. You might struggle with stubborn immiscible pairs using old-school solvents. EGDE’s attitude helps researchers skip unpredictable conditions or awkward workarounds.

Let’s not sugarcoat the risks, though. Being too easy-going means EGDE opens doors to more than just water. It slips right past many plastic containers, softens rubbers, and escapes through seals. Storage calls for real vigilance. Glass works, but don’t trust every piece of plastic in your lab. Stories of ruined equipment and lost samples get traded as cautionary tales more often than you’d guess.

Whether you’re in pharmaceuticals, coatings, or electronics, solvent choice can mess with your whole process. A user-friendly solvent might cut costs by making the cleaning phase shorter or letting you recover more product from a reaction vessel. Water-miscibility sometimes means you no longer need flammable or toxic alternatives, improving workplace safety. Historical blunders—from contaminated groundwater to flare-ups during transfer—show that solvent properties shape much more than a single chemistry experiment.

Mixing water with a solvent like EGDE looks easy on paper, but there’s always a tradeoff. I’ve learned to store volatile, reactive solvents far from hot plates and crowded benches. The smartest labs keep logs of which plastics react badly, and everyone gets drilled on what to do if there’s a leak. For those who need green chemistry solutions, some companies tweak solvent blends or recommend tighter safety barriers. Still, with strong solvent properties, the only sure way forward is respect for the stuff you’re using and a willingness to tweak old routines.

At the end of the day, simple questions like, “Can I mix this?” are really about time, cost, safety, and sometimes outright disaster. Getting those basics right keeps the wheels turning, whether you’re brewing up pharmaceuticals or running undergraduate experiments. Mixing chemistry and practical know-how pays off more often than not.

| Names | |

| Preferred IUPAC name | 2-ethoxyethoxyethane |

| Other names |

1-Ethoxy-2-ethoxyethane Diethoxyethane Ethyl cellosolve Ethylene glycol diethyl ether EGE |

| Pronunciation | /ˌɛθ.ɪˌliːn ˈɡlaɪ.kɒl daɪˈiːθəl ˈiːθər/ |

| Identifiers | |

| CAS Number | 112-36-7 |

| 3D model (JSmol) | `load code/ethyleneglycoldiethylether` |

| Beilstein Reference | 1201325 |

| ChEBI | CHEBI:40458 |

| ChEMBL | CHEMBL1200842 |

| ChemSpider | 13385 |

| DrugBank | DB14116 |

| ECHA InfoCard | 100.008.826 |

| EC Number | 203-940-0 |

| Gmelin Reference | 8859 |

| KEGG | C19682 |

| MeSH | D017226 |

| PubChem CID | 8065 |

| RTECS number | KK7175000 |

| UNII | QWJ2M14FSC |

| UN number | UN1171 |

| Properties | |

| Chemical formula | C6H14O2 |

| Molar mass | 134.18 g/mol |

| Appearance | Colorless liquid |

| Odor | sweet odor |

| Density | 0.869 g/mL at 25 °C |

| Solubility in water | Soluble |

| log P | -0.43 |

| Vapor pressure | 0.6 mmHg (20°C) |

| Acidity (pKa) | 14.7 |

| Basicity (pKb) | pKb: 5.14 |

| Magnetic susceptibility (χ) | -55.6×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.403 |

| Viscosity | 1.7 mPa·s (20 °C) |

| Dipole moment | 1.76 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 416.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -400.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3735.8 kJ/mol |

| Pharmacology | |

| ATC code | D07AX |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H302, H319 |

| Precautionary statements | Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking. Avoid release to the environment. Wear protective gloves/protective clothing/eye protection/face protection. IF ON SKIN: Wash with plenty of water. |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | Flash point: 50°C (122°F) |

| Autoignition temperature | 180 °C |

| Explosive limits | 3.1–23.5% |

| Lethal dose or concentration | LD50 (oral, rat): 2,052 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5.85 g/kg (oral, rat) |

| NIOSH | KWG76500 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Ethylene Glycol Diethyl Ether: "100 ppm (540 mg/m³) TWA |

| REL (Recommended) | 2.5 ppm |

| IDLH (Immediate danger) | 900 ppm |

| Related compounds | |

| Related compounds |

Ethylene glycol dimethyl ether Diethylene glycol diethyl ether Diethylene glycol dimethyl ether |