Ethylene glycol dibutyl ether didn’t stumble into laboratories overnight. This compound’s history trails back to a period when chemical industries raced to tweak glycol ethers for custom uses. Chemists kept stacking carbons and butyl groups onto familiar backbones, searching for solvents that would handle water, oils, resins, and everything between. Through decades of incremental progress, industrial labs landed on this specific molecule—finding somewhere a sweet spot between solubility and volatility. Ethylene glycol dibutyl ether came together as bigger players in paint-making, electronics, and plastics needed solvents that wouldn’t eat at metals but could push tricky reactions just enough to matter.

This chemical doesn’t jump out as flashy, but its strengths hide in its balance. It works as a colorless, oily liquid, found in factories and research labs that depend on glycol-based solvents. Vendors bottle and sell it for use in coatings, degreasers, inks, cleaners, breaking apart grease and dissolving compounds that water alone can’t touch. Some folks in the lab reach for ethylene glycol dibutyl ether almost by reflex: it blends qualities from ethylene glycol and butyl ethers, dissolving polar and nonpolar things alike.

At room temperature, you’ll notice ethylene glycol dibutyl ether remains stubbornly in liquid form, only boiling at about 256°C and freezing around -65°C. The faint fruity odor tips you off before serious exposure, but evaporation isn’t rapid. Density hovers just under one gram per cubic centimeter, a bit heavier than water. It mixes with organic solvents quite easily. Water solubility stays moderate—enough to be useful, never high enough to cause headaches about runaway hydration. This chemical shrugs off many acids and bases but reacts when provoked by strong oxidizers.

Producers label drums and cans with its CAS number—112-96-9—and slap on warnings about skin and eye irritation. Labels spell out purity, generally above 98%, and chart out moisture or low-level contaminants if buyers want reassurance. The UN number guides shipping, and storage instructions insist on sealed containers, cool and ventilated rooms, far from sources of ignition or sunlight. These aren’t just bureaucratic hoops; slip-ups here spill over into ruined product batches or worker safety risks.

The reactor setup pulls from classical etherification. Labs often start by feeding ethylene glycol into a vessel, add a base catalyst, then run dibutyl halide into the mix under heat. Vapors get scrubbed away, and the product needs drying and fractionation under reduced pressure. Sometimes, leftovers from the butyl source force extra purification, so columns and separating funnels come into play. Scaled-up manufacturers tweak the workflow, but the backbone of glycol meets butyl group remains steady and practical.

Chemists lean on ethylene glycol dibutyl ether for its resistance to hydrolysis and oxidation, but they don’t treat it like glass. It can form peroxides when left in contact with air for too long—prompting labs to check for traces before distilling down. Strong acids chew through it and cleave the ether linkages, so keeping it away from industrial acid streams counts for a lot. On purpose, labs turn to the molecule in Grignard reactions, or for carefully coaxing water-sensitive chemicals into solution.

The naming soup surrounding this molecule usually includes ‘Dibutyl Cellosolve,’ ‘Butylglycol Ether,’ and ‘2-(2-butoxyethoxy)butane.’ Reagent catalogs may call it by its IUPAC name, but workers often stick to shorter trade names, making for easier communication on the warehouse floor. No matter the name, savvy users keep CAS numbers handy to avoid confusion between similar glycol ethers.

Ethylene glycol dibutyl ether deserves respect in the workspace. Lab coats, gloves, and eye protection remain the unwritten uniform. Factory floors make the rules more explicit, running through spill drills and mandating exhaust hoods where vapor might stray. Breathing in fumes can irritate the respiratory tract and cause nervous system symptoms on bad days—or after long exposures. Good employers circulate safety data sheets, keep showers and eyewash stations within reach, and store the chemical away from reactive stocks.

Daily life doesn’t put this compound in front of most people, but footprints run deep in paints, varnishes, and printing inks. Its solvent action smooths out sticky polymers in coatings, keeps metal degreasers washing clean parts, and pops up in specialty cleaners more often than the label might let on. Printed circuit boards rely on it to remove stubborn residues without wrecking the fragile traces underneath. Each industry twists the solvent’s properties to crack challenges that water and weaker ethers can’t handle—a tool where the job demands flexibility and reliability at once.

Not every R&D project marks its progress in headlines, but scientists keep mining for improved glycol ethers where current options fall short. Work continues on designing derivatives with lower toxicity, brighter environmental profiles, or specialties for energy storage and novel polymers. Some scientists tinker with the chain lengths, hunting for ethers that break new ground in selective solubility or faster biodegradability. Finding those next-generation compounds depends on what today’s standards can and can’t do.

Some solvents in this class turned up on regulatory radar when studies linked high doses to organ changes or reproductive issues in lab animals. Ethylene glycol dibutyl ether generally slips through most workplace safety checks with proper handling, but accidental exposure—skin, lungs, or worse, ingestion—demands real caution. Chronic effects remain less discussed in the open literature, but regulatory agencies review new research closely. Replacing high-exposure tasks with automation or enclosed handling answers lingering toxicity worries better than relying on fail-prone personal equipment.

Next steps for ethylene glycol dibutyl ether depend not just on chemistry, but where regulations and manufacturing demands meet. Stricter rules could shift demand toward greener substitutes if toxicity data moves policymakers to act. Some engineers work on recycling or catalytic breakdown to chop down the environmental load of spent solvents. Others survey broader uses: lithium battery research, high-performance coatings, or streamlined extraction in pharmaceutical manufacturing. The compound may lose ground if safer cousins jump ahead, but end-users still depend on its unique chemistry for tough jobs, at least until something better delivers equal results without drawbacks.

Walk through any modern manufacturing facility and odds are, there’s a drum of ethylene glycol dibutyl ether tucked somewhere among the raw materials. Few folks outside chemical plants spare a thought for the clear liquid in those heavy blue barrels, yet it plays a quiet but important role in plenty of places. Factories producing specialty paints, inks, and coatings depend on it to keep their products smooth and workable. If you’ve ever rolled fresh paint onto a wall or seen a glossy finish on printed packaging, you’ve seen what this solvent helps achieve.

Production teams like using ethylene glycol dibutyl ether because it dissolves certain chemicals that wouldn’t otherwise mix easily. This means chemists and engineers can formulate products with just the right flow or feel. You need a solvent that won’t evaporate too quickly when making these products—if it does, applications become uneven, clumpy, and filled with streaks. This particular ether boils at a higher temperature than many other options, sticking around long enough to do its job and then clearing out without leaving unwanted residue.

It’s not just about smooth application, either. It slows down drying when you need a paint to remain workable a bit longer, giving workers precious time to get details right or to cover larger surfaces evenly. Once the job wraps up, the solvent heads out, leaving behind a neat, clean finish.

There’s more to this compound than pretty surfaces. Industries handling metal cleaning and degreasing take advantage of ethylene glycol dibutyl ether’s ability to break up oily grime that simple soap can’t touch. Automotive and electronics manufacturers also bring it in when rinsing delicate parts—its careful balance between power and gentleness keeps equipment safe while banishing stubborn films.

Some battery makers turn to it while producing electrolytes for high-performance batteries. Lithium batteries—powering everything from phones to electric cars—benefit from additives that can boost stability and keep the cells working longer. Choosing the right compounds here means more reliable, longer-lasting power.

It’d be wrong to skip over some challenges. Any chemical that cleans and dissolves with this much strength needs careful handling. Breathing in vapors from ethylene glycol dibutyl ether for too long, or letting it touch your skin repeatedly, brings health risks that workers can’t ignore. Companies train employees to use gloves, masks, and ventilated workspaces. On top of that, regulators like OSHA (Occupational Safety and Health Administration) set exposure limits, so there’s a real push to keep the workplace safe.

Waste management is another piece of the puzzle. Spill some of this solvent and it can travel quickly through soil and water, so responsible disposal matters. Smart operations invest in containment and treatment plans, and some move towards recovery methods that let them recycle what they use instead of tossing it. Cleaner, closed-loop systems serve both the company’s bottom line and the community’s health.

There’s a steady hunt for less toxic alternatives. Green chemistry researchers experiment with bio-based solvents and compounds that cut down on both health risks and environmental footprints. Still, the performance and cost profile of ethylene glycol dibutyl ether keep it in demand across several fields. Until a bigger breakthrough arrives, careful use paired with strong safety practices will keep it a key ingredient behind the scenes.

Ethylene Glycol Dibutyl Ether brings some useful qualities to the table as a solvent in the chemical world. Nobody doubts its value for lab work and industry. It has a knack for helping mix things that usually wouldn’t go together. What usually goes unmentioned, though, is the real risk that follows every time you open a bottle, pour it out, or clean up after a spill.

A while back, early in my lab days, I watched someone assume gloves are enough. Cold hands, sweating under nitrile, thinking that’s full coverage. One splash changed the mood. Ethylene Glycol Dibutyl Ether goes through regular gloves fast, not much warning before skin absorbs it. Inhaling the vapors can cause dizziness, headaches, and even more serious problems if exposure drags on. Some people shrug off the warnings. That doesn’t mean they’re safe.

There’s a chronic side too. Prolonged exposure—skin or lungs—can start to mess with your liver or kidneys over time. Nobody thinks about that in the moment, but years add up. Even small spills that get overlooked can build up nasty side effects.

A good chemical handling setup always starts with decent ventilation. Fume hoods or proper extraction—skip shortcuts; fans in windows won’t cut it. Airflow is something you can’t fudge just to save a few bucks. For people who use this solvent regularly, keeping a spill kit nearby is just part of the routine. Paper towels and wishful thinking won’t clean up something dangerous.

Equipment matters. Not every glove stands up to organic solvents. Butyl rubber or laminated gloves hold up better. Cheap goggles fog up and don’t always seal right. A decent pair of chemical splash goggles and a lab coat go a long way—better yet, something rated against solvents. A good habit: no eating, drinking, or careless habits around it. It’s not only about spills. Cross-contamination happens faster than folks expect.

I remember a storage room in an old building where strong smells would hit you before you opened the door. Bottles left half-sealed, not labeled, sharing shelves with acids. Ethylene Glycol Dibutyl Ether should stay in its own spot, away from acids, strong oxidizers, and out of the sun. Metal cabinets with flame-resistant features make sense here, not plain wooden shelves. Containers should lock tight, and anything showing wear or a crack in the lid belongs in the hazmat bin, not back on the rack.

It’s not glamorous, but the basics of spill response save a lot of heartache. Baking soda or other neutralizers shouldn’t be grabbed blindly. Look up what works for ethers. For smaller spills, absorbent pads do the job, but watch where they go—hazardous waste streams only. For bigger spills or fires, call in the trained responders. I’ve seen the cost of “fixing it yourself” pile up: ruined equipment, shut labs, and sometimes a lost job.

Rules on paper never stopped a mess. Training new folks by walking them through situations helps more than any printed protocol left to collect dust. The places I’ve seen build real safety cultures have steady reminders and shared stories about close calls. People look out for each other, not just check boxes. That attitude, not high-tech gear, really draws the line between routine days and disasters.

Handling chemicals like Ethylene Glycol Dibutyl Ether carries steady risks. Simple respect for the material and a willingness to slow down make all the difference. “Hurry up” drives more accidents than anyone wants to admit.

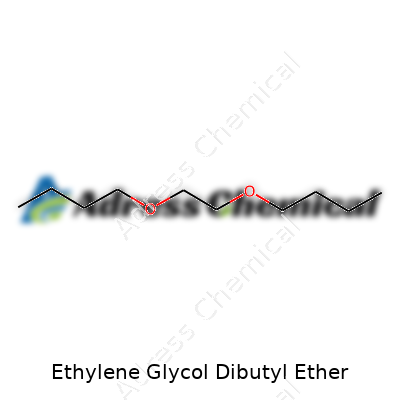

Ethylene glycol dibutyl ether goes by the formula C12H26O2. Its structure brings together two butyl groups on the ends, hugging an ethylene glycol backbone. Visually, it’s a clear, colorless liquid with a faint smell. The substance shows a boiling point hovering near 241°C, much higher than most household solvents. Given its low solubility in water, it stays separated in most water-based settings but blends smoothly with organic compounds and hydrocarbon-based mixtures.

The story of ethylene glycol dibutyl ether stretches past simple chemical interest. Folks in industry tend to use it as a specialty solvent. Paint strippers, resins, and inks lean on this ether for its solid solvency without too much volatility. Chances are, many people come across objects processed with this stuff but never realize it. It helps dissolve tricky compounds or extend shelf life since it doesn’t vanish into the air the way alcohols or acetone do. With years of work in laboratories and a fair bit of hands-on experience handling custom solvents, I learned that ethylene glycol dibutyl ether often pops up when we need powerful dissolving abilities but can’t stick with low-boiling alternatives like diethyl ether.

This ether’s low flammability draws attention in settings where safety counts. Its flash point sits up at 95°C—well above room temperature—so fire risk during daily use falls far below acetone or petroleum ether. Safety managers care about that as much as any lab tech does. Big spills still raise eyebrows since inhalation and direct contact can irritate the skin, eyes, or respiratory tract. Strict gloves and goggles rule the day. Nobody jokes around with concentrated organic solvents, even those known for mildness.

Toxicity data on ethylene glycol dibutyl ether doesn’t stack up to the horror stories around things like benzene, but long-term effects haven’t been explored enough. Older studies mostly looked at short-term skin and eye irritation, or sniffing vapor at concentrations far above occupational limits. The U.S. Occupational Safety and Health Administration (OSHA) sets rules around exposure, sharply limiting airborne concentrations on the job.

Waste management lands on the desk of every lab supervisor and production manager. This ether doesn’t break down quickly in soil or water, staying persistent unless collected for proper chemical disposal. My experience dealing with chemical inventories taught me that even a “mild” solvent can slip through cracks in the system and turn up in ground runoff or air emissions. Stronger controls around storage and documentation help plug those gaps, but there’s always room for more environmental mindfulness.

People working with ethylene glycol dibutyl ether already have safety protocols, but there’s always a push for improvement. Closed systems limit vapor leaks, and fume hoods make a difference, especially for high-volume users. Researchers keep scanning for greener alternatives that bring similar muscle in dissolving polymers or resins without the downsides.

Community right-to-know laws—requiring clear labeling and emergency plans—push companies to treat substances like this one with respect. While ethylene glycol dibutyl ether doesn’t grab headlines, it’s another link in the chain of chemicals that demand awareness, not just from specialists but from everyone touching the supply line.

Ethylene Glycol Dibutyl Ether isn’t as famous as acetone or ethanol, but some chemicals just find their way into workshops, labs, and factories because their unique properties work where most others fail. This solvent can help dissolve things that stump standard chemicals, but it pays to know how to store it safely. I’ve dealt with many chemicals over the years working with paints, coatings, and occasionally synthetic labs. Poor storage always leads to wasted money, heartbreak, or scary moments you don’t want on your conscience.

This ether doesn’t beg for constant attention, but the risk of flammable vapors sneaking out when it’s left in the wrong spot isn’t worth the shortcut. I’ve walked past more than one storage closet where solvents sat without enough ventilation—once you pick up that familiar sweet smell, trouble isn’t far behind. Even if nobody is smoking nearby, a static shock or electric switch can spark problems.

The key here: put containers in a cool, dry spot away from any chance of flame or sparks. Metal safety cabinets built for solvents often stand in a shaded spot, away from doors and sunlight. At work, our best setups avoid direct sun—sun not only heats up everything but UV rays can degrade many chemicals over time. A few signs reminding staff not to keep rags, cardboard or any absorbent trash nearby go a long way in keeping fire risks low.

Some solvents chew through containers faster than a raccoon in a dumpster. In my experience, Ethylene Glycol Dibutyl Ether handles steel or high-quality glass with no complaints, but cheap plastics warp or leak before long. Steel drums with self-closing lids, or solid glass bottles with tight stoppers, have always kept everything where it should be.

Labeling shouldn’t just be ink on masking tape. At my old job, we switched to dedicated solvent-resistant labels and double-checked hazard symbols. If you need to grab a bottle in a hurry, squinting at faded marker isn’t just annoying; it’s dangerous. Arrange bottles so the oldest stock gets used first—expired solvent is a headache waiting to happen.

Moisture sneaks in easily if storage caps don’t fit right. Water in an ether turns it into a useless mess, sometimes with some nasty by-products as a bonus. After cleaning up a spill caused by a cracked cap, I never underestimate humidity. Store the ether somewhere dry, and check caps and seals every month. If the workplace has a dehumidifier, keep it running. If you ever smell anything odd—sour, odd, or just plain wrong—it’s time to get the supervisor or chemical safety team involved.

Only take out as much as a job needs—leaving the lid off for even 20 minutes adds a risk. I’ve seen people top off squeeze bottles and forget them overnight. By morning, the solvent level had dropped, and the room reeked. Always put leftover solvent back where it belongs. Don’t return used solvent to the main drum—it’s almost impossible to know what contaminants just got added.

Real-world safety boils down to routine. Forgetting steps, or just getting sloppy, leads to injuries and lost product—something my coworkers learned after a small but expensive fire in a corner storage shelf. Take care, follow the simple steps, and storage hassles hardly ever happen.

Ethylene glycol dibutyl ether isn’t a chemical you’ll find sitting on a common household shelf. It plays its part in labs, factories, and specialty shops—mostly as a solvent. The trouble with any specialty solvent, though, comes from what it might do when you throw other chemicals into the mix. Many solvents earn their keep because they interact well with a set group of compounds, but just as often, they can start trouble if tossed together with the wrong thing.

I spent years in a research lab that loved to experiment with solvent mixtures. Not every combination was safe. So I learned to check the chemical compatibilities each time I set up a new blend, especially with ethers and glycols. I remember the sharp smell of ethylene glycol ethers—the sort that seeps into your nose and lingers—and the careful looks folks gave the compatibility charts. Getting this wrong risked fires, toxic fumes, ruined experiments, or legal headaches if you had an accident to explain.

Take ethylene glycol dibutyl ether and strong oxidizers. Blend those together, and the risk of a runaway reaction jumps. Peroxides are a worry, too. Ethers can form them over time, turning what looks like a clear liquid into a booby trap for the careless. Laboratories keep containers well-sealed, dated, and stored away from sunlight because of this hazard. It’s not paranoia when the risk involves a literal explosion.

Put this chemical next to strong acids or bases and the story isn’t much happier. Acidic environments crack ethers into smaller fragments, sometimes poisonous. Bases can do the same. There isn’t a tidy middle ground—if the Safety Data Sheet raises a red flag, it’s for good reason. Mixing with plastics, too, gets tricky. Some polymers just crumble after soaking in ethers for weeks. There’s nothing worse than coming in to find your collection bottles soft as putty and leaking contents all over the bench.

Course-correcting this mess starts with solid training. New hires or students can’t wing it with solvents like ethylene glycol dibutyl ether. Real hands-on practice—figuring out what gloves to wear, what containers won’t break down, and what to do if a spill happens—beats a stack of paperwork every time. I learned more from a crusty lab tech with thirty years’ scars on his hands than from any textbook section.

There's also value in slow and steady preparation. Before mixing any chemicals, pulling technical sheets, reading compatibility tables, and asking someone with more time in the field keeps most disasters far away. Modern labs rely on digital inventory systems and up-to-date chemical management lists, not just memory or colored tape markers. Departments chip in for regular waste disposal, and stubborn containers go for testing before anyone risks opening them.

Chemical compatibility isn’t a side concern—it’s front and center wherever real people work with dangerous stuff. Ethylene glycol dibutyl ether reminds me of this every time I spot it on a reagent shelf. Treat each new mixture with skepticism, trust what the old timers say, and respect the collection of cautionary stories hung on every corkboard near the safety shower. That spirit of healthy doubt keeps workspaces safe—and reputations intact.

| Names | |

| Preferred IUPAC name | 1,2-Bis(butoxy)ethane |

| Other names |

1-Butoxy-2-(2-butoxyethoxy)ethane Butyl diglycol ether Dibutyl carbitol Butyl ether of diethylene glycol Diethylene glycol dibutyl ether |

| Pronunciation | /ˌɛθ.ɪˌliːn ˈɡlaɪ.kɒl daɪˈbjuː.tɪl ˈiː.θər/ |

| Identifiers | |

| CAS Number | 112-48-1 |

| Beilstein Reference | 1102209 |

| ChEBI | CHEBI:31297 |

| ChEMBL | CHEMBL2104855 |

| ChemSpider | 74495 |

| DrugBank | DB14163 |

| ECHA InfoCard | EU-Information-Card: 100.012.162 |

| EC Number | 211-076-1 |

| Gmelin Reference | 169681 |

| KEGG | C19582 |

| MeSH | D017163 |

| PubChem CID | 8136 |

| RTECS number | KI8575000 |

| UNII | 16E85P836E |

| UN number | UN2526 |

| CompTox Dashboard (EPA) | DTXSID7030672 |

| Properties | |

| Chemical formula | C10H22O2 |

| Molar mass | 202.32 g/mol |

| Appearance | Colorless liquid |

| Odor | Mild |

| Density | 0.87 g/cm3 |

| Solubility in water | Insoluble |

| log P | 1.63 |

| Vapor pressure | 0.02 mmHg (20 °C) |

| Acidity (pKa) | pKa ≈ 15.1 (for the hydroxyl group in ethylene glycol backbone) |

| Magnetic susceptibility (χ) | -64.0e-6 cm³/mol |

| Refractive index (nD) | 1.417 |

| Viscosity | 1.706 mPa·s (20 °C) |

| Dipole moment | 1.35 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 489.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -429.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4946.7 kJ/mol |

| Pharmacology | |

| ATC code | D08AX06 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. H319: Causes serious eye irritation. H332: Harmful if inhaled. |

| Precautionary statements | P210, P280, P305+P351+P338, P370+P378, P403+P235 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | Flash point: 81°C |

| Autoignition temperature | 180 °C |

| Explosive limits | Explosive limits: 0.7–8.3% |

| Lethal dose or concentration | LD50 Oral Rat 3300 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral-rat 2,300 mg/kg |

| NIOSH | K0126 |

| PEL (Permissible) | PEL: 5 ppm |

| REL (Recommended) | 5 ppm |

| IDLH (Immediate danger) | IDLH: 100 ppm |

| Related compounds | |

| Related compounds |

Ethylene glycol diethyl ether Ethylene glycol dimethyl ether Diethylene glycol dibutyl ether Propylene glycol dibutyl ether |