The story behind Diethylene Glycol Propyl Ether Acetate traces back several decades, weaving through the evolution of solvent technology and coating chemistry. Before solvents of its kind emerged, manufacturers leaned heavily on more volatile and less efficient chemicals, which brought challenges in both workplace safety and environmental damage. As industries faced tighter regulations and sought better alternatives, glycol ether acetates began gaining attention for their ability to balance performance and reduced toxicity. The compound occupies a sweet spot for many users searching for predictable evaporation rates and good solvency power. Its utility has only grown as coatings, inks, and adhesives needed cleaner-burning, less hazardous solvents to support stricter emission and safety standards.

Diethylene Glycol Propyl Ether Acetate appears as a clear liquid, sporting a faint odor that often gives away its glycol backbone. Its boiling point usually sits higher than many traditional solvents, and most people working with it notice the mild, almost “soft” evaporation. Flash points hover in a safer range, lending it favor where fire hazards constantly lurk. The liquid doesn’t mix freely with water but shows an uncanny ability to dissolve resins and polymers that would turn their nose up at water alone. Its molecular architecture packs enough flexibility through ether bonds to work across different formulations, from paint thinning to ink flow adjustment.

Technical details shape every decision around this chemical. With a molecular weight tipping over 246 g/mol, a density that usually lands just around 1 g/cm³, and viscosity values that grant good leveling, processors rely on its numbers to maintain consistency. Purity often ranks above 98%, as even minor impurities could sabotage a whole batch. Safety data sheets lay out the essentials: hazard codes, recommended personal protective gear, required first aid, and environmental disposal practises. Labels use easy-to-spot identifiers like the CAS number (e.g., 88917-22-0), but names like Propylene glycol diethylene glycol acetate or simply PGDEA also crop up, depending on supplier and region.

Production strolls through classic organic synthesis, marrying diethylene glycol fragments with propyl group donors alongside an acetic acid esterification. These steps sound dry on paper, but an insider knows the dance between pressure, temperature, and catalyst tweaks can put entire facilities at risk or deliver the perfect run. Tweak the ratios or screw up the timing, and results swing between dazzling success and expensive cleanup. Once produced, chemical engineers shift focus to blending, monitoring stability, and testing reactivity for every downstream purpose.

Chemists keep a close watch on its behavior with acids, bases, and oxidizers because unwanted reactions could foul equipment or bring shifts to a halt. Its acetate group elevates it above simple glycol ethers, opening possibilities for further modifications. The marketplace recognizes it under several handles: Diethylene Glycol n-Propyl Ether Acetate, PGDEA, and various local trade names. This mish-mash in naming can trip up procurement unless people double-check CAS codes and specs every time.

Lab veterans hold a deep respect for the risks in mishandling solvents like this. Splashes irritate skin and eyes, and the vapors tend to hang in the air if spaces lack proper ventilation. Nobody wants a fire scare, so flash point awareness sits front and center. Respiratory protection and gloves aren’t suggestions, but routine essentials. Facilities develop waste procedures to avoid fouling waterways or air, mindful of environmental compliance and company reputation. Mistakes rarely just cost money—they can lead to lost time, health episodes, or even injuries no one forgets.

Ask anyone in coatings, printing, or electronics about must-have solvents, and Diethylene Glycol Propyl Ether Acetate makes most lists. It keeps surface finishes smooth, helps colors pop in printing, and manages good compatibility with a range of modern resins. Electronics firms appreciate its measured approach to evaporation, allowing delicate parts to dry cleanly without creating pinholes or trapping residues. This versatility carries over into cleaning fluids and even some specialty adhesives, broadening its importance across sectors not usually known for sharing supplies.

Teams continue chasing cleaner, safer, and more effective uses for glycol acetate derivatives. Papers and patent filings detail ways to fine-tune its performance, lower environmental load, and shrink toxicity profiles. Concerns around emissions, long-term occupational exposure, and unexpected reactivity drive fresh cycles of study. Universities and industry labs keep collaborating to develop improved monitoring technology, faster detection in complex mixtures, and safer substitutes for niche scenarios.

Personal exposures, even brief, highlight how little room for error this compound offers. Dermal and inhalational contacts show irritation in lab tests, and high doses, rare outside disasters, tip into headaches, dizziness, or worse. The chemical walks the edge between manageable and hazardous. Regulations demand close tracking and immediate reporting of accidental releases. Monitoring blood or air concentrations for production workers remains a key precaution, especially in older facilities less fitted to modern standards.

Solvents like Diethylene Glycol Propyl Ether Acetate straddle past and future, carrying lessons from past mistakes as well as future ambitions. Engineers and chemists don’t stop at compliance, searching for green chemistry solutions that slash emissions and reduce risk to both people and planet. Recycling practices, recovery systems, and substitution research sit high on agendas for conferences and grant funding alike. From my years around plant floors and formulation labs, one thing stays certain—progress isn’t just about better specs; it’s about making sure everyone goes home safe and the environment doesn’t pay the price for industry’s demands. Innovators who stay grounded in real-world risk while pushing technical boundaries will set the pace for how chemicals like this one shape industries in decades to come.

I’ve noticed that many people glide past chemicals with long names, like diethylene glycol propyl ether acetate, as if they didn’t matter. Yet, this clear liquid links quietly to everyday life, especially in the worlds of paint, electronics, and printing. We know it by its role as a solvent—a substance that helps dissolve other stuff so it spreads or mixes better. Walk into a freshly painted room or use a smartphone, and you’ve crossed the path of this solvent, whether you realized it or not.

Paint has to stick right and dry smoothly, otherwise nobody’s happy. Factories lean on diethylene glycol propyl ether acetate to break down pigments and resins, ensuring paints don’t clump and dry too fast. It gives paint that workable “open time” so folks can roll, brush, or spray without ugly streaks. During hot summer afternoons in my old apartment, the slower-drying paint always came out more even—part of that is this type of solvent doing its everyday job in the background.

Automotive paint shops count on it for the same trait. Dings and scratches from a city parking lot get fixed up with paints that rely on a solvent for smooth application and a tough, lasting finish. Skimping on quality or substituting something else can result in bubbling or peeling—nobody wants that on their car’s hood.

Electronics manufacturing depends on absolute cleanliness. Printed circuit boards don’t work if residue lingers. Here, the solvent washes away unwanted flux after soldering or gets rid of grease and oily fingerprints. I once watched a local repair tech wipe down a board with a solution containing this chemical—it helped remove grime without harming delicate components.

Printers, especially in high-volume commercial shops, lean on similar chemistry. The ink formulations need a balance so they don’t smudge, dry on the roller, or block up tiny nozzles. A carefully chosen solvent like diethylene glycol propyl ether acetate ensures ink flows, dries, and sticks as expected, page after page.

Some household products use solvents of this kind too. Spot removers, graffiti cleaners, and a few specialty surface cleaners carry it on their ingredient list. Small shops and hobbyists use it for thinning lacquers or cleaning brushes, since old-fashioned turpentine often smells worse and carries more health warnings.

Even though diethylene glycol propyl ether acetate solves a lot of manufacturing headaches, workers face health questions. Prolonged exposure or spills lead to skin or eye irritation, so good ventilation and protective gloves make sense. The factories I’ve toured take these steps seriously. With repeated use, chemicals that seem mild enough still deserve respect.

Some regulators have flagged the solvent for review, not because it has caused household disasters but out of caution. Ensuring safe air and clean water around plants takes planning, especially in older facilities. Many companies already have disaster response plans, but newer substitutes may lessen risk over time if they perform as well.

The world’s not going paint-free or phone-free any time soon. Solvents like diethylene glycol propyl ether acetate play quiet, overlooked roles that deserve attention—especially as society asks more questions about safety and sustainability. Industry, regulators, and workers can keep looking for safer pathways or new blends, but for now, this humble chemical quietly helps keep the modern world running clean and colorful.

Diethylene Glycol Propyl Ether Acetate isn’t a common topic at the dinner table, but it’s everywhere in the painting and coating world. I've spent years working around chemicals like this, and too often folks only think about safety after an accident, not before. So, before cracking open that drum, habits around protection make the difference between an ordinary day and an emergency room visit.

One memory sticks out — I once finished a shift without gloves on, and by the next day my hands felt dry and irritated. Skin absorbs this solvent quickly. There’s no substitute for nitrile or neoprene gloves. Simple latex gloves don't stand up well to aggressive solvents. I stopped counting how many times someone grabbed the closest gloves, only to learn later their hands tingled or turned red. Keeping your skin covered, with long sleeves and a good chemical apron, keeps accidents from turning into injuries.

Splashes sneak up fast. It takes just an instant to regret skipping goggles. Standard safety glasses with side protection or full-face shields keep eyes clear and sharp through the day. A single drop can burn a cornea, and I’ve watched coworkers wait too long to rinse — an eyewash station nearby never feels like overkill.

I started out working in a stuffy room, no fans, just the hum of machinery. After a week, headaches were the norm. Solvent vapors, especially from chemicals like this, build up quickly. Air flows better with windows open and fans running. A fume hood or a proper exhaust system pulls vapors away from your face, turning a dangerous job into a manageable one. Proper ventilation isn’t a luxury as much as it’s an unwritten rule. Industry guidelines set strict exposure limits for a reason—nobody wants headaches, dizziness, or worse because the air felt stuffy.

Spills happen—someone bumps a can or the drum leaks. It pays to have spill kits close. Granular absorbents, chemical-resistant mops, and sealed disposal bags let you react quickly. Cleaning up with bare hands or regular towels brings trouble. I’ve learned that assumptions and shortcuts only spread the mess and the risk. Mark the area and clear others away until everything’s clean. Afterward, wash exposed skin with soap and water, even if you didn’t feel a thing.

Heat speeds up chemical reactions, so those drums belong in a cool, shaded spot. Sealing all lids tightly blocks fumes and prevents moisture from getting in—solvents and water never mix well. I label everything with waterproof markers big enough to read across the room, because faded text isn’t helpful when you’re rushing. Lock up chemicals, far from curious hands and flammable material, to avoid preventable accidents.

Safety gear only goes so far without real understanding. I’ve lost count of times coworkers ignored training refreshers, thinking they knew it all. People remember stories and dry facts equally, so mix both into any safety talk. Regular drills make the difference. Knowing what to do without panic, whether it’s flushing eyes or sounding the alarm, keeps a small mistake from spiraling out of control. Simple routines build a culture that shields people from bad surprises.

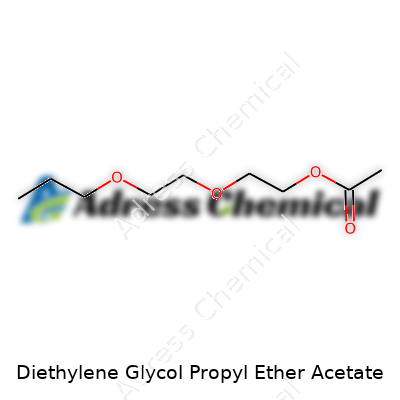

Diethylene glycol propyl ether acetate sounds like something best left in a lab notebook, but its role in the real world is impossible to overlook. Its chemical formula, C11H22O4, tells more than a simple story. What actually lies behind those numbers is a molecule designed with purpose. Picture a backbone built from two ethylene glycol units, bonded by oxygen, carrying a propyl group and dressed up as an acetate ester. In diagrams, you’ll see it written as CH3COO(CH2CH2O)2C3H7. This structure gives it a blend of water-loving and oil-loving sides, something chemists call amphiphilic, which lets it do some pretty clever things.

Breaking down the pieces helps. The acetate group (CH3COO-) comes from acetic acid. That’s your vinegar component, so it’s got a familiar scent but in this context, lives long past the kitchen. The diethylene glycol part gives the molecule flexibility and makes it easier to dissolve both water-based and oil-based substances. Propyl ether groups on the tail increase its ability to mix with less polar compounds like resins and certain paints.

In my own work with coatings and cleaning products, I’ve seen how a single change in molecular construction can flip the story. This molecule, thanks to its ether linkages and that acetate finish, acts as a powerful solvent. It slips into acrylic and urethane coatings, making them dry slowly and smoothly. You won’t see paint "blushing" (getting that chalky, cloudy look) nearly as often with it in the mix. Cleaning industries use it for just this reason—it breaks up grease without leaving streaks or residue, and it won’t destroy delicate surfaces the way some harsher solvents can.

Comparison with alternatives sheds light on why manufacturers keep coming back to it. Straight-up propylene glycol or just diethylene glycol don’t do quite the same job. They’re either too slow, not quite compatible, or bring along unwanted odors. Adding an acetate cap solves those problems and makes a product that’s both versatile and far less irritating to skin and lungs than the more aggressive solvents from years past.

Any compound that dissolves paint or stubborn grease still raises flags. Diethylene glycol itself has a checkered past, with accidental poisonings in pharmaceuticals due to poor regulation. In the hands of responsible professionals, though, this acetate derivative gets handled with care. Safety glasses, gloves, and proper ventilation all matter. Long exposures or large spills demand attention, because some glycol ethers can carry risks to reproduction or organ health.

Regulators in the US and Europe follow diethylene glycol propyl ether acetate closely. They set occupational exposure limits and keep an eye on disposal methods because of how chemicals like these can leak into waterways or the air. With the right precautions, companies can enjoy the benefits without feeding into health or environmental issues. For smaller shops and personal use, clear labeling and access to good safety data sheets go a long way.

I’ve watched the trend toward greener, safer solvents pick up speed in recent years. Folks in R&D are hustling for alternatives that still work in high-performance coatings but break down faster after use, or that pose less health risk during production. In the meantime, tools like closed-loop recycling and improved fume extraction—old-school in some circles—show plenty of merit. Over time, the chemistry underlying diethylene glycol propyl ether acetate helps point toward solutions that keep both performance and safety in focus.

Diethylene Glycol Propyl Ether Acetate doesn't roll off the tongue easily, and it's not something most folks want to spill on the floor. This liquid gets a fair bit of use in industries making paints, coatings, inks, and cleaning products. Even though it quietly boosts productivity and creates smooth finishes, there's a hidden edge to it. Inhalation, skin contact, or accidental mixing with food or drink can cause irritation or worse. That’s not just a workplace headache, but a serious health hazard. Stories of chemical mishandling don't just surface in distant factories—any place where safety gets skipped, trouble sneaks in.

Most warehouses lose track of temperature control out of convenience. Yet, this compound should live inside a cool and well-ventilated space, away from direct sunlight. Too much warmth and light can break down the chemical over time and pressure can build up in containers. In that state, leaks and spills don't seem so far-fetched. Airflow keeps the vapors from pooling, reducing fire risks and the potential for workers to breathe in fumes. I learned this lesson during a summer heat wave at a paint facility, where poor placement made inventory a hazard. Air conditioning and vents cost less than one emergency.

Some substances love to react, and leaving Diethylene Glycol Propyl Ether Acetate near acids or oxidizers sets up more than just a headache. There’s a reason chemical-compatible shelving and separate rooms exist. One slip-up—bandsaw shavings landing in an open drum or the wrong cleaning agent touching a puddle—can turn routine chores into dangerous situations. I’ve seen spilled solvent fizzle and smoke after a rag used for acids landed nearby. Cross-contamination makes a small mistake much bigger, fast.

It really pays to pick containers meant for strong chemicals. Tight seals and corrosion-resistant materials—think steel drums with secure lids or sturdy plastic carboys—keep liquids in and moisture out. Don’t save money by reusing old paint buckets or food-grade packaging. Even reputable facilities cut corners on old barrels, only to deal with slow leaks and damaged labels months later. Clear labeling saves lives: include hazard symbols, chemical name, and date received. If the label peels away or the drum looks bulged, move fast. Ignoring a dented drum almost always leads to spills.

No matter how neat the shelf or modern the HVAC system, mistakes happen. Spill kits, eye wash stations, and fire extinguishers should be visible and accessible. Every time I ran through chemical safety drills, the team groaned at the repetition—until someone actually got splashed, and the kit was the reason there wasn’t a trip to the hospital. Quick action is only possible if the right tools are already in arm’s reach. Everyone storing this chemical should have a written plan for spills and leaks, one that doesn't sit forgotten in a drawer.

A well-ventilated room or safety manual shouldn’t gather dust. Workers need to recognize real dangers. Training that shows what can go wrong leaves a stronger memory than a list of don’ts. I’ve watched safety meetings where employees pointed out genuine hazards missed by their managers, just because they spent time near the barrels each day. Listening to the team on the ground makes a difference and reduces accidents.

Diethylene glycol propyl ether acetate goes by a technical name, but up close, it looks pretty simple. You end up with a clear, colorless liquid. Hold a bottle up to the light, and you won’t notice much for color. It doesn’t carry a strong smell either, at least not like the solvents people think of from high school chemistry where the stench can chase you from the room. The liquid feels a bit thicker between the fingers compared to water, but not as sticky as syrup or oil. Folks often don’t see much difference in appearance from one batch to the next.

This compound boils around 235°C to 245°C. That's pretty warm. It takes a lot more heat to turn this liquid into steam than it does with water (which boils at only 100°C). This sort of boiling point keeps the liquid stable in heated manufacturing. Factories working with coatings and inks push temperatures up, so stability at high heat becomes a real selling point. A solvent that won’t just turn into vapor as soon as you add warmth means you can mix and process formulas with far less hassle.

Solubility matters. Some solvents just won’t play nice with water, while others accept water easily. Put diethylene glycol propyl ether acetate in water and you see only partial mixing—some dissolves, some doesn’t, so you end up with a mixture, not a solution. In non-polar solvents, like oils or some paints, this chemical blends all the way. It acts almost like a middleman, bridging water-based and oil-based mixtures to bring everybody together in the same batch. In the real world, formulating with this compound means you can tweak a product’s properties with unusually fine control, making it easier to get the right flow, drying time, or surface appearance.

Properties like appearance, boiling point, and solubility look scientific at a glance, but for people who work in paints, coatings, inks, and even some cleaners, these details make daily work smoother. Take coatings, for example. A high boiling point means workers can spread paint smoothly and let it dry slowly, without it flashing off too fast, which creates a mess of bubbles and rough surfaces. This single feature can cut down on wasted time and product.

It’s also about safety. You don’t want to work with a liquid that vaporizes at the drop of a hat. Strong fumes in an enclosed plant bring health risks, and environmental-facing companies need to reduce emissions. A solvent that stays in liquid form longer actually helps contain those problems. By relying on this kind of stable, barely-scented solvent, workplace conditions improve, and so does the final product’s safety profile.

The fact that this chemical mixes only partly with water means operators must take care to store and use it alongside the right partners. Looking at future solutions, people have started pairing these kinds of solvents with newer additives that boost water compatibility. Research in coatings keeps driving towards blends that act like oil-based products during use but rinse out or break down safely with water in the environment. Some new “green” solvents built from the same backbone now offer similar high boiling points, but with better water solubility, which helps both in manufacturing and with washing up afterward. Change like this makes workplaces both safer and more flexible.

| Names | |

| Preferred IUPAC name | 2-(2-Propoxyethoxy)ethyl acetate |

| Other names |

Diethylene Glycol Monopropyl Ether Acetate Propylene Glycol Diacetate Propoxyethoxy Ethyl Acetate 2-(2-Propoxyethoxy)ethyl acetate DEGPE Acetate |

| Pronunciation | /daɪˈɛθiːliːn ˈɡlaɪˌkɒl ˈprɒpɪl ˈiːθər əˈseteɪt/ |

| Identifiers | |

| CAS Number | 6881-95-6 |

| Beilstein Reference | 3462781 |

| ChEBI | CHEBI:88857 |

| ChEMBL | CHEMBL2175201 |

| ChemSpider | 121349 |

| DrugBank | DB14121 |

| ECHA InfoCard | The ECHA InfoCard of Diethylene Glycol Propyl Ether Acetate is "100.124.957". |

| EC Number | 309-978-2 |

| Gmelin Reference | 1633549 |

| KEGG | C19594 |

| MeSH | D003975 |

| PubChem CID | 11247838 |

| RTECS number | KH8220000 |

| UNII | QH5C3O62G6 |

| UN number | UN3271 |

| CompTox Dashboard (EPA) | DTXSID8050937 |

| Properties | |

| Chemical formula | C11H22O4 |

| Molar mass | 218.28 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Mild |

| Density | 0.977 g/cm³ |

| Solubility in water | Miscible |

| log P | 0.51 |

| Vapor pressure | 0.045 mmHg @ 25°C |

| Acidity (pKa) | 9.53 |

| Basicity (pKb) | pKb: 13.68 |

| Magnetic susceptibility (χ) | -7.44×10⁻⁶ |

| Refractive index (nD) | 1.415 |

| Viscosity | 1.1 mPa.s (25°C) |

| Dipole moment | 2.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 589.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -759.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4662.7 kJ/mol |

| Pharmacology | |

| ATC code | NO ATC |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes serious eye irritation. May cause drowsiness or dizziness. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P301+P310, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 72°C |

| Autoignition temperature | 185 °C |

| Lethal dose or concentration | LD50 (oral, rat): 5150 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 3089 mg/kg |

| NIOSH | Not established |

| PEL (Permissible) | Not established |

| REL (Recommended) | 5 ppm (skin) |

| IDLH (Immediate danger) | No IDLH established. |

| Related compounds | |

| Related compounds |

Diethylene Glycol Diethylene Glycol Monoethyl Ether Diethylene Glycol Monobutyl Ether Ethylene Glycol Monopropyl Ether Acetate Propylene Glycol Monomethyl Ether Acetate Triethylene Glycol Monomethyl Ether Acetate |