Curiosity about glycol ethers began to pick up speed during rapid industrialization after World War II. Chemical engineers hunted for compounds that expanded the toolkit for formulating paints, solvents, and cleaners. Diethylene glycol monopropyl ether (commonly abbreviated as DGPE or DEPGPE) made its entrance during these years, stepping out as different industries explored propylated glycol chains for their balanced solvency and low volatility. During the 1960s and 70s, stricter workplace regulations around hazardous solvents pushed research labs to dig deeper into alternatives like DGPE, especially as companies demanded safer replacements for more toxic or flammable solvents. My grandfather, working in a lacquer factory, often talked about the shift in product safety with new glycol ethers coming to market, and how it changed workplace norms at the time.

DGPE usually shows up as a colorless liquid — it doesn’t shout with an odor, making it easier to work around than many harsh-smelling solvents. The fluidity, combined with its moderate evaporation rate, lands it in a sweet spot for use in everything from cleaning fluids to specialty ink vehicles. On labels or shipping documents, you’ll spot names like “Propyl Oxy Diglycol” or “3-Oxapentane-1,5-diol monopropyl ether.” Manufacturers sometimes prefer their own naming spin, but most chemical suppliers use standard synonyms so it’s clearer for industrial buyers.

DGPE’s boiling point hovers around 235–240°C, a notch higher than simple alcohols or many petroleum-based solvents. This lowers flammability concerns, making fire codes easier to satisfy at production sites. With a molecular weight that tends toward 176.2 g/mol and a density landing near 1.01–1.03 g/cm3, it pours and stores like water, keeping inventory straightforward. The miscibility with water and a broad range of organics opens up a lot of potential for blending in different product lines, from latex paints to degreasers. The vapor pressure stays low at ambient temperatures, which not only means it stays put in a product for longer but also reduces inhalation risks for workers.

Chemists don’t ignore the details, so critical specs like purity frequently run above 99%. Labels must display its CAS number (29911-27-1), UN number if shipped internationally, and warning statements tied to workplace exposure limits. Safety data sheets (SDS) remain the backbone, as every drum, tote, and bottle travels with documents listing emergency spill procedures and first aid advice. Warehouse staff typically scan for flammability ratings and note compatibility cautions, especially next to strong oxidizers or acids. In my own experience with chemical purchasing, the accuracy of those labels and SDS can make or break a smooth auditing process from regulators.

Production relies on the etherification reaction between diethylene glycol and propyl alcohol using acid catalysts. The reaction requires careful temperature control to avoid breaking the glycol chain or producing unwanted byproducts. Manufacturers often recycle unreacted starting materials to squeeze every bit of value out of the process. Large-scale reactors churn out consistent batches, but small changes in pH or temperature can affect the outcome. Safety around the reactor never gets ignored, since the vapor of hot alcohols can ignite if not well contained.

DGPE’s ether backbone delivers real versatility. It resists hydrolysis and typical oxidation under mild to moderate conditions, so it stays stable in harsh paint formulations. Direct modification remains tricky, given the stability of the ether bond, but specialty chemists have grafted segments and created block copolymers with similar glycol ethers to tweak solubility profiles. No revolution here, but plenty of incremental improvements that expand the toolkit for formulating more efficient inks, lubricants, or even certain pesticide emulsions.

Depending on where you stand in the supply chain, the same chemical goes by a parade of names. “DEGPE,” “Diethylene glycol n-propyl ether,” “Dowanol DPM” (a related compound), and “Arcosolv PnP,” plus some distributor-specific product codes, all refer to closely related glycol ethers. Purchasing managers and shipping clerks rely on CAS numbers to cut through the marketing clutter. Trade shows and industry publications showcase these various names, but any savvy industrial buyer double-checks the documentation before approving a shipment.

Rules around glycol ethers tightened sharply after concerns about toxicity from related compounds emerged. Plants using DGPE tend to enforce tight PPE requirements, plus local exhaust ventilation for transfer and blending processes. Storage drums require clear UN-rated stickers. U.S. OSHA and European REACH guidelines demand training so workers spot hazards early, especially since glycol ethers can absorb through the skin. Engineering controls and regular health checks aren’t just box-ticking exercises; they actually prevent serious long-term health issues, something colleagues have emphasized after dealing with minor symptoms from accidental exposures in the past.

DGPE pulls its weight not just in labs, but factories, print shops, and cleaning-supply warehouses. Water-based paint makers use it to keep pigment flowing smoothly and prevent streaking. In commercial glass-cleaning fluids, it cuts through grease without leaving a cloudy film, sidestepping the streaks customers always point out. Ink suppliers rely on DGPE for consistent drying times. Electronics-makers have trialed glycol ethers (including DGPE variants) in PCB cleaning and solder flux removal because they lift residues without eating away modern plastics. A good chunk of the chemical finds its way into pesticide and herbicide formulations, helping stubborn molecules dissolve more easily so they spread evenly in water.

Research groups focus on pairing DGPE with other glycol ethers in specialty blends for faster cleaning or more environmentally friendly coatings. Labs in the U.S., Europe, and East Asia push processing tweaks to reduce byproduct generation and improve recyclability. Developers experiment with additives that will shorten drying times without raising worker exposure risks. Regulatory pressure in California, the EU, and elsewhere means ongoing scrutiny. Most R&D departments swing between finding cheaper ways to produce DGPE and reducing the total volume needed per finished product, thanks to improved formulation science.

While considered safer than certain short-chain glycol ethers, DGPE still makes safety managers sweat. Animal studies show repeated skin exposure or inhalation leads to mild central nervous system depression and potential liver or kidney irritation — not acute, but enough to warrant caution. International health agencies track it closely, and recent research delves into whether chronic low-level exposure has long-term health outcomes. Companies increase transparency by publishing workplace monitoring data and sponsoring independent inhalation and dermal absorption studies. Where possible, product stewards switch to closed transfer systems and switch from manual handling to reduce the risks.

The future demands greener profiles and stronger regulatory compliance. DGPE has room to grow in the water-based coatings and cleaning fluids market, especially as solvent bans push older alternatives aside. Bio-based routes from renewable glycols and alcohols see attention in academic journals but still face hurdles with scaling up. Expanded toxicology data will shape the way policy and procurement work across the industry. Automation and digital supply tracing hope to prevent accidental exposures and improve emergency response for spills or leaks. More companies set target dates for reducing or eliminating traditional glycol ethers, pushing investment into alternatives or low-impact blends. The story of DGPE highlights that change isn’t theoretical. It’s an everyday balancing act between chemical performance, worker safety, environmental responsibility, and regulatory rules written halfway across the globe.

Spend any time around paints, cleaners, or inks, and you’ll start to recognize the chemical names in the ingredient lists. Diethylene glycol monopropyl ether, despite its heavy-sounding name, plays an unglamorous but important role in plenty of products that surround us. This isn’t the star ingredient, but pull it out, and a lot of those everyday items fall short of what they promise.

Walking through a freshly painted hallway, the smell hits first. Behind that distinctive scent, there’s a blend of solvents at work, and this particular glycol ether steps in to help paint spread evenly. Without it, you’d see more streaks and clumpy patches. Paint hardens too quickly on the brush, dragging and bubbling without laying down a smooth layer. Cutting corners on a solvent like this brings out headaches for both contractors and home DIYers. In the world of coatings, performance matters, because nobody enjoys redoing an entire wall that never quite dries right.

Kitchen counters, bathroom tiles, workbenches — most cleaners for tough jobs need a little extra boost. Diethylene glycol monopropyl ether slips quietly into these formulas, breaking down grease, fingerprints, smudges, and a host of stubborn marks. All-purpose cleaners, degreasers, and surface wipes use it not to impress, but because it just works. My own dive into cleaning out a garage showed how the right solvent turns a multiday ordeal into a couple of hours and fewer broken fingernails. People look for quick results and don’t worry much about what goes into that bottle, though a little curiosity never hurt.

Printing presses, both big and small, run smoother thanks to solvents like this one. Inks dry at the right rate on paper, whether for newspapers, boxes, or the weekly grocery flyer. Drying too fast means clogs, drying too slow gives messy prints. Techs who spend their lives beside those clattering presses know the difference. For illustration, a jammed printer or runny ink in my student years usually meant losing half a day and showing up empty-handed to class. Behind every clean printed sheet, there’s a chemical story playing out.

Factories producing dyes, leather goods, and adhesives lean on this solvent for both process and finished product. Textile factories often rely on it to make dye mixing easier. Glues that need to stay workable until that last piece fits benefit from the right kind of solvent. It keeps adhesive from turning to sludge, sticky in the tube but useless by the time you squeeze it out.

Anyone working near chemicals pays attention to the warning labels. Diethylene glycol monopropyl ether isn’t something to splash around lightly. Too much exposure—whether on skin or through vapors—brings headaches, skin irritation, or worse with careless use. Workplaces with open drums and high-volume mixing need careful ventilation and real safety gear, not just open windows. At home, storing bottles up high and tightly closed keeps curious kids, pets, and even grownups from trouble.

More people ask about what washes down the drain or ends up in landfill. Companies look for formulas that break down faster or use less of the tough stuff. My conversations with eco-friendly painters and cleaners show a push toward water-based options, but old formulas stick around unless alternatives really work. Finding better answers demands steady pressure—customers, regulators, and workers all get a say in what comes next.

This solvent holds more importance than most shelves and supply closets let on. Where performance, safety, and environmental impact all matter, diethylene glycol monopropyl ether sits at a crossroads. Most people touch products made with it every week, often without knowing. If you care about what comes into your home, pay attention to where this compound turns up, and ask how the makers handle it. That curiosity leads to smarter choices and, over time, maybe safer shelves for all of us.

Most folks outside of labs and industry rarely hear about Diethylene Glycol Monopropyl Ether. The name rolls off the tongue like gravel, and hidden inside that mouthful is a solvent with a reputation for versatility. Painters, cleaners, and formulators count on it to dissolve grease and boost solutions, but few stop to think about what comes with the package. Decades spent around chemicals have made me allergic to clichés, so let’s get straight to what matters: this is a liquid that demands respect. Too many workers have gambled with shortcuts around safety, figuring nothing bad ever happens to them—until it does.

Spend enough time in a warehouse or blending room and you catch the difference between a cold or allergic sniffle and what comes from exposure to the wrong vapors. Diethylene Glycol Monopropyl Ether gives off a faint odor, tricking you into thinking it’s harmless, but vapors add up. Prolonged inhalation may trigger headaches, dizziness, and, with heavier doses, even respiratory irritation. I once tried to clean machinery with insufficient ventilation; lightheadedness warned me quick. Always open doors and windows. Exhaust fans aren’t extras. If an environment traps air, this chemical will linger in it. Rely on a proper mask—goggles and gloves, too—before even uncapping that drum. Bare hands quickly absorb solvents, and good gloves keep skin rashes and deeper health risks at bay. Over the years, I’ve watched coworkers tough it out, only to deal with splitting, dry skin weeks later.

Every veteran in the field has at least one story about a splash to the eyes. Even a little solvent sting will ruin a day—worse if you don’t reach the eyewash station in time. Goggles with a snug side shield block these unpredictable accidents. Many solvents eat away at cheap lenses, so buy a pair built for chemical work and keep them handy, not buried in a drawer.

Solvents like these don’t mix well with carelessness or makeshift storage. Store it in a cool, dry spot—out of the sun, away from any open flames or spark sources. Once, I witnessed a makeshift shed stacked with chemical drums right next to a heater, just because space was tight. You don’t want to become an example on a safety slideshow. Use metal or corrosion-resistant containers, and make sure all labels are clear and intact. Small leaks turn into big cleanups, so double-check that every cap is tight and every drum secure. Familiarity breeds shortcuts, so don’t trust your memory—always read those labels before grabbing a jug.

Spills happen, even to the careful. Speed matters. Absorbent pads, sand, or commercial spill kits soak up liquid before it spreads. Never use water to wash it down a drain; that only scatters the problem or sends it into the environment. Bag up used materials and bring them to a hazardous waste facility or arrange for collection—don’t dump them in regular trash. At one place I worked, a lazy sweep and mop sent residue into a storm drain. Cleanup became the city’s problem and cost many times more than doing it right the first time.

No equipment outlasts good habits. Training means more than a quick safety video—pair up newcomers with experienced staff and run drills for handling leaks, spills, and exposures. My advice is always learn where the eyewash and showers stand before starting the job, not after you need them. If something feels off—a strange odor, eye sting, or even just odd fatigue—pause and check it out. Chemicals don’t cut breaks for overconfidence.

Working with Diethylene Glycol Monopropyl Ether rarely rewards taking chances. Gloves, goggles, ventilation, and attention to detail never slow a shift as much as a visit to the med room. After years on job sites, that’s what sticks with me: nothing replaces daily respect for what’s in the drum and the people working beside you.

Diethylene Glycol Monopropyl Ether, usually shortened to DEGPE, turns up everywhere from cleaning formulas and inks to specialty coatings. Chemists and folks in industry care about whether these substances dissolve or blend fully with other liquids, especially water. That’s often the practical test for easy use on the production line.

The thing with DEGPE is it doesn’t fight with water. Drop it in, and these two combine well at room temperature. This full blending comes out of DEGPE’s chemical makeup, with both ether and alcohol groups tucked inside. Those bits inside the molecule grab onto water just as well as they grab other solvents, which smooths out mixing jobs.

This blending power isn’t just chemistry trivia. In my time working with lab technicians and formulating floor cleaners, easy dissolving has made the difference between a clear, streak-free finish and a cloudy mess. When DEGPE goes straight into water, factories save steps and lower costs. It saves time — which is always at a premium in production runs.

Blending with water at any ratio helps in places like water-based paints, where even a small patch of separation can wreck a batch. Watching a vat turn into a smooth mix with no lumps or cloudiness tells you a solvent truly pulls its weight on the floor. No expensive equipment, no complicated extra heating, just direct results.

Water may grab most of the headlines, but solvents stretch way beyond that. DEGPE also slides into alcohols, like methanol and ethanol, without fuss. Its structure opens space for both water-loving and oil-friendly molecules, so it doesn’t shy away from hydrophobic partners like hydrocarbons.

I’ve seen DEGPE added right into solvent-based inks and coatings where other ingredients can be tricky. It keeps formulas stable, stops them from separating, and carries pigments or cleaning agents evenly across a surface.

Sometimes, folks worry about reactions with strong acids or bases, but short-term mixing with most common solvents or water runs smooth for industrial purposes. It’s rare to see negative feedback about bad blending or ruined batches — a testament to DEGPE’s broad compatibility.

Problems usually come up when users neglect basic checks before large-scale mixing. Ignoring differences in viscosity or temperature changes can trip up even seasoned staff. Overheating a solution or skipping a small-scale test batch might lead to haze or separation, though DEGPE usually fares better than more stubborn solvents.

Plants that keep to routine checks, control temperatures, and introduce solvents in correct order avoid headaches. I always recommend running tiny sample blends before turning on the big mixers. Keeping detailed notes about ratios, ambient temperature, and stirring speed pays off many times over. It’s easy to get comfortable, but the cost of a ruined drum could be thousands, and no one wants to answer for a batch gone bad over a skipped step.

Companies searching for safer, greener solvents have started swapping traditional options for water-miscible choices like DEGPE. Instead of leaning only on tradition, teams should consider well-tested solvents that make day-to-day work easier and safer. Regulatory pressure and customer expectation for lower toxicity add a real push for substances that don’t foul up easy mixing or cleanup.

Blending success isn't just a chemistry lesson — it’s the ground under good manufacturing and safe working conditions. If more folks understood just how much time and money simple miscibility saves, decision-makers might be quicker to choose the solvent that avoids problems from the start.

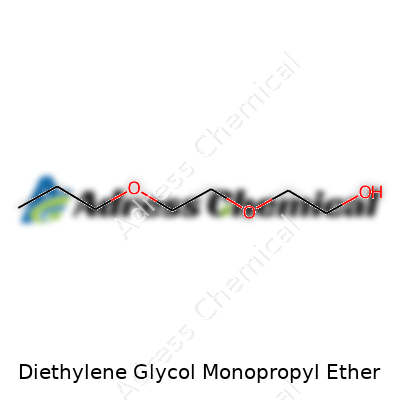

In daily life, not many folks recognize the name Diethylene Glycol Monopropyl Ether, but in a lab or manufacturing setting, knowing the basics means something. The chemical formula sticks out: C7H16O3. This little string of letters and numbers keeps everything clear. Each molecule packs seven carbons, sixteen hydrogens, and three oxygens. Trust me, knowing the basics of what’s in a beaker saves you from headaches, both literal and regulatory. It also comes with a registration number—every chemist swears by these. The CAS number is 6881-94-3, and scribbling that into paperwork makes it easy to track.

Back in my college lab, the difference between one chemical and another could be the one that saves a project from blowing up (sometimes literally, if you’re clumsy). Mixing up formulas or relying on generic names never helped anyone. Precise identification can make or break product quality. If someone working with coatings thinks they have propylene glycol but picks up Diethylene Glycol Monopropyl Ether by mistake, the final product turns out wrong. Garbage in, garbage out. At scale, mistakes like that cost real money and could send people scrambling for safety showers.

Experience shows, you can’t just assume two clear liquids act the same. With a proper CAS number, safety data gets pulled in seconds. Diethylene Glycol Monopropyl Ether isn’t the most dangerous substance out there, but long-term exposure never does your liver any favors. Some people get rashes, some feel dizzy. These facts aren’t just details for safety posters; they serve as warnings to anyone wearing a lab coat. Handling guidelines don’t get enforced on gut instinct. Every worker in factories using this chemical deserves proper ventilation, gloves, and clear instructions in a language they understand.

Someone buying or selling industrial solvents can’t just go off a brand or casual nickname. Regulatory filings, shipping manifests, and compliance paperwork need airtight accuracy. Governments track chemicals like Diethylene Glycol Monopropyl Ether down to the ounce in certain cases, especially if it gets near food, pharmaceuticals, or anything aimed at kids. Missing a digit on a CAS number means the wrong file lands on the wrong desk, and life becomes an avalanche of fines, recalls, or legal headaches. I once saw a paint shop lose thousands because paperwork for a similar-sounding glycol didn't match the drums on site.

Every operation that depends on chemicals runs smoother when formulas and CAS numbers are respected. Proper labels cut down on confusion. Regular training drills the right habits—never skip this step, even for experienced hands. On the logistics side, digital inventory systems that hunt by CAS number work wonders, flagging shortages and preventing someone from grabbing the wrong canister. For anyone working with Diethylene Glycol Monopropyl Ether, a little extra attention to chemical identity saves time, money, and keeps people out of harm’s way.

In an industry where details make the difference, never discount the power of a clear chemical formula or that unique CAS number: 6881-94-3 for Diethylene Glycol Monopropyl Ether. In my experience, carrying this respect for detail from the lab bench to the loading dock sets up everyone for a safer, more efficient day. Whether you pour it, mix it, or just log it, knowing the right identifiers beats learning the hard way.

Diethylene Glycol Monopropyl Ether might not sound like something most people run into, but this liquid finds its way into plenty of workplaces—cleaners, coatings, inks. Think of it almost like the workhorse nobody notices, chugging away on the factory floor to keep the gears turning. Tucked away in big drums or tanks, it can carry risks that often get overlooked.

Warehouse workers, long-haul drivers, even office folks who handle paperwork, all depend on making sure these chemicals stay where they belong. Heat, leaks, bad ventilation—all of these pose threats that feel pretty real once you’ve seen a minor spill turn into a full-blown crisis. If you've ever had to clean up after a leaking container, you know it’s not something you forget.

Stashing this solvent away from heat sources sounds easy, but in reality, crowded storage rooms sometimes force tough decisions. Space fills up, boxes get stacked too close, and the next thing you know, drums sit near a heating vent. It matters because Diethylene Glycol Monopropyl Ether can break down and release irritating fumes. Good ventilation saves more than just noses. It keeps everyone out of the sickbay and on the job.

A well-sealed, labeled drum might look boring, yet it forms the backbone of daily safety. Companies sometimes try to stretch every penny, but using the wrong container often means regrets later. Imagine grabbing a rusted barrel or a mystery tank with faded writing—it’s a recipe for trouble. Regulation calls for steel or high-quality plastic, with leak-proof seals and legible hazard information. Using the right label keeps deliveries smooth and keeps emergency crews from guessing in a pinch.

I’ve seen shared warehouses where cleaning chemicals sat one aisle away from packaged food or drink containers. That made a few people nervous, with good reason. Diethylene Glycol Monopropyl Ether can cause health problems if it gets inside the human body. Even if separation costs a few minutes at the start and end of the day, it stops headaches down the line—both the literal and the legal kind.

The unsung hero of chemical storage isn’t a tank or a valve—it’s the person who catches leaks before they spread. The people on the ground need actual training, not just a dusty manual on a shelf. Fire extinguishers should sit nearby, and spill kits can't be an afterthought. Regular drills and updated safety sheets help turn complicated protocol into muscle memory. From my own experience, nobody regrets a well-run safety walkthrough. On the flip side, guessing at what to do mid-crisis never ends well.

Skilled truck drivers handle hazardous materials every day, but mistakes still crop up. Proper tie-downs, stable pallets, and careful stacking keep containers upright. Any rough bump or sudden stop adds risk. Logistics teams must map routes that dodge busy human spots and double-check paperwork to avoid seizure or misdelivery. Once, a missed weight check meant an entire truckload had to be restacked in the rain—a waste of hours and a reputational black eye for the distributor.

Nothing beats routine. Regular inspections for corrosion or leaks, fresh training for new hires, and quick access to emergency contacts form the foundation of safe operations. Mixing up storage locations or skipping a maintenance round might look harmless for a day, but can put people and property in harm’s way. Investing in strong processes, even when they cost a bit more or take a little extra time, always pays off in the end—mostly by making sure everyone goes home safe, day after day.

| Names | |

| Preferred IUPAC name | 2-(2-Propoxyethoxy)ethan-1-ol |

| Other names |

2-(2-Propoxyethoxy)ethanol Propyl Carbitol Propylene diglycol ether DEPG Diethylene glycol propyl ether |

| Pronunciation | /daɪˈɛθiːliːn ˈɡlaɪˌkɒl mɒnəˈprəʊpɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 111-96-6 |

| Beilstein Reference | 1421440 |

| ChEBI | CHEBI:81338 |

| ChEMBL | CHEMBL1656840 |

| ChemSpider | 20582 |

| DrugBank | DB14155 |

| ECHA InfoCard | ECHA InfoCard: 03f9a824-0182-40b8-9a57-806b3e0e6ffc |

| EC Number | 252-104-2 |

| Gmelin Reference | 1539101 |

| KEGG | C19579 |

| MeSH | D017250 |

| PubChem CID | 8214 |

| RTECS number | UB8200000 |

| UNII | 3M1OVY8957 |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C7H16O3 |

| Molar mass | 134.18 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 0.982 g/cm³ |

| Solubility in water | Miscible |

| log P | 0.74 |

| Vapor pressure | 0.008 mmHg @ 25°C |

| Acidity (pKa) | 14.8 |

| Basicity (pKb) | 5.06 |

| Magnetic susceptibility (χ) | -52.2×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.424 |

| Viscosity | 2.9 mPa·s (25°C) |

| Dipole moment | 4.82 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 309.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -632.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4828.6 kJ/mol |

| Pharmacology | |

| ATC code | D01AE22 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. May cause respiratory irritation. |

| GHS labelling | GHS07: Exclamation mark |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. H319: Causes serious eye irritation. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P264, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | “Flash point: 107°C (225°F) (Closed cup)” |

| Autoignition temperature | 224 °C |

| Lethal dose or concentration | LD50 oral rat 3089 mg/kg |

| LD50 (median dose) | 2980 mg/kg (rat, oral) |

| NIOSH | UB2325000 |

| REL (Recommended) | 5 ppm (19 mg/m³) |

| IDLH (Immediate danger) | No IDLH Established |

| Related compounds | |

| Related compounds |

Diethylene Glycol Monoethyl Ether Diethylene Glycol Monomethyl Ether Diethylene Glycol Monobutyl Ether Ethylene Glycol Monopropyl Ether Triethylene Glycol Monopropyl Ether Propylene Glycol Monopropyl Ether |