Chemistry classes back in school skimmed past compounds like diethylene glycol methyl ethyl ether, though its story stretches far beyond textbooks. Originating from early solvent development trends in the chemical industry, this ether didn’t immediately grab headlines. In the late 20th century, manufacturers looked for solvents that handled water-insoluble substances without raising the same toxicity flags as predecessors like diethylene glycol itself. Around that time, new methods for controlling chain length and functionalization led to the appearance of this glycol ether variant. Research journals tracked its uses in lab-scale and then industrial-scale syntheses. Over the years, as industries grew more international, regulatory pressures steered new solvents into the market, including this one. So its presence reflects growing caution and evolving understanding within chemistry circles.

In the lab, the reagent bottle labeled with its much longer name easily gets confused with other glycols and ethers. The product sports a clear, colorless liquid appearance, somewhat reminiscent of other familiar ethers. Its mild, almost sweet odor sets it apart from harsher chemicals. Bottles feature familiar hazard icons, as regulations and workplace safety rules changed in recent decades. Brands often sell it under a blend of trade names and synonyms, which can trip up even seasoned chemists: diglyme, carbitol, and a handful of systematic names, each with international roots. That assortment of names crops up in shipping manifests, inventory spreadsheets, and chemical catalogues.

Pulling data straight from lab tables and safety data sheets, this compound boils at 196–202°C and melts around -70°C. With a density near 0.95 g/cm³ and high miscibility with water and many organic solvents, it transitions seamlessly between laboratory and plant settings. Viscosity and vapor pressure both favor safe storage, preventing sudden evaporation, while its ability to dissolve both polar and non-polar substances provides unique leverage in formulating products that resist phase separation. Chemists value its stability under standard conditions but know to keep it away from oxidizers and acids. Even slight departures in chemical purity—from contaminated storage, for instance—may tweak those base properties and prompt reanalysis before critical tasks.

Labels in storage rooms must now spell out far more detail than even a decade back. Lot numbers, purity grades—often 99% or higher for analytical applications—are standard fare. Transportation packaging highlights United Nations numbers (UN2810, in many cases), hazard statements, and pictograms. Over the years, documentation grew to include batch analysis, which frustrated small-lab users but offered greater security to industrial operators or importers facing customs checks. Each step up in certification means increased traceability, with corresponding price jumps. Long gone are single-label, generic stock bottles, replaced by barcodes, QR tags, and catalog cross-references, corresponding to increasingly rigorous global chemical control regimes.

Manufacturers scale up diethylene glycol methyl ethyl ether through the reaction of ethylene oxide with methanol and ethanol in controlled steps, carefully titrating catalysts and temperature. Large reactors, jacketed pipes, and careful distillation train operators to respect both quality and safety thresholds. Historically, varied feedstock purities led to inconsistencies, but advances in process control reduced unwanted byproducts and routine labor. Chemists involved in process work often recount the complexity of separating desired ethers from a broader glycol soup. The process illustrates the move away from batch synthesis to continuous flow, improving yields and workplace conditions. Many old-timers remember open-vent hood work, but today's process is far more contained, limiting exposure and environmental escape.

Diethylene glycol methyl ethyl ether plays a flexible role in reaction schemes. Chemists draw on its solvent capabilities to conduct reactions involving esters, dyes, and pharmaceutical intermediates where reaction partners differ in polarity. Under strong acid or base, the ether linkages face cleavage, opening up possibilities for tailored transformations, though typically the compound resists easy degradation under ambient conditions. It rarely participates as a starting material for further etherification—other glycols dominate that role—but does enable polar aprotic solvent conditions prized in organic synthesis. People working in coatings and inks industry may tweak the molecule at pressure and temperature edges to form functional blends, chasing improved flow, stability, or drying times.

Walking through a chemical distributor’s warehouse, you'd find tags that echo each company's branding strategy: DEGEE, methyl carbitol, 2-(2-ethoxyethoxy)ethanol, or simply EC. Some European markets list proprietary blends, especially for specialty solvent applications and water-based paints, muddying the waters for inventory managers. I recall early days fumbling through catalogues, searching for CAS number 111-90-0 to settle debates over which bottle matched the project at hand. Misidentification happened in the past—often costly, sometimes dangerous. Each manufacturer leans on slightly different synonyms, intensifying the need for clear, consistent labeling, especially as internet commerce widened the playing field.

Safety culture around glycol ethers evolved through hard lessons and injury reports. Gloves and goggles remain a minimum requirement, but now fume hoods and air monitoring entered standard practice where use volumes climb. Chronic exposure can introduce skin and eye irritation, with regulatory authorities classifying some glycol ethers as reproductive hazards, leading labs and factories to take a more conservative stance. Spills receive immediate attention, with absorbent pads, containment systems, and specialized waste bins. Training extends from formal certifications to on-the-job mentorship, with older workers sharing stories about mishaps or health complaints long before current standards. Today’s rules demand far more than periodic spot checks—continuous process monitoring backs up periodic workplace exposure assessments.

Diethylene glycol methyl ethyl ether found homes in painting, printing inks, and cleaning agents. Its balance of hydrophilic and lipophilic properties allows inks to wet diverse surfaces—I've seen its uses expand during trips to industrial paint shops and printrooms where consistency over large surface areas is paramount. Surfing chemical catalogs for solutions to tough solvent problems, technical staff in electronics cleaning or coatings production often land on this glycol ether because it threads the needle between volatility and solvency. It soldiers on in indoor and outdoor surface treatments, helping products resist the elements. In analytical labs, it serves as a reference solvent and carrier in sample preparation, filling a unique gap between more aggressive or less compatible solvents.

Research teams keep probing new uses for this glycol ether, driven partly by environmental rules and cost structures. Paint companies test tweaks in formulation to meet stricter emissions goals, swapping or adjusting glycol ethers to limit volatile organic compound release. Pharmaceutical R&D explores roles as a solvent for drug delivery, though toxicity concerns dampen widespread medical uptake. University labs publish work on reaction optimization, solvent recycling, and green chemistry alternatives that keep this compound viable in certain niches. Regulatory pressure spurs innovation; companies keep looking for drop-in replacements or modifications that retain performance while improving safety. Personal experience from R&D meetings reveals how discussions often pit tradition against new safety data, leading to spirited debates over process modifications and research priorities.

Studies tracing glycol ether toxicity informed major safety regime shifts in the chemical sector. Researchers linked direct exposure to acute symptoms—headache, dizziness, skin irritation—but long-term health tracking showed impacts on organ development and reproductive health in animal models. This eventually triggered restricted use lists in certain regions. Occupational health teams rolled out more rigorous air sampling and biological monitoring, which sometimes confirmed elevated risk. I recall training seminars where toxicologists outlined how metabolism transforms glycol ethers into slightly more potent byproducts, raising alarm in communities dependent on solvent-heavy industries. The push for lower workplace exposure thresholds reflects findings from this emerging data, not merely regulatory crackdowns. Real stories from industrial settings make the case for vigilance; reports of illness and injury remind us that behind every chemical lies a responsibility to both staff and surrounding communities.

Industries always scan for greener, safer chemicals, yet practicality and cost slow big changes. As environmental regulations toughen and consumer demand tilts toward safety, diethylene glycol methyl ethyl ether will either need to adapt or step aside for biobased or lower-toxicity contenders. Innovation may find ways to recycle the solvent, lower emissions, or engineer safer blends. Real change often starts in the lab but faces hurdles scaling for industrial adoption—limited supply chains, variable raw material quality, and entrenched processes all slow momentum. Efforts to redesign synthesis routes or explore biodegradable derivatives reflect an ongoing struggle between the need for performance and demands from regulators. Whether it remains a staple depends on continuing successful navigation of health, safety, and environmental benchmarks stacked higher each year.

People talk a lot about chemicals that sound like they come from some secret lab, but often these names pop up in things we run into just about every day. Diethylene Glycol Methyl Ethyl Ether, for instance, goes by the nickname DEMEE and finds itself in places few folks suspect. I first ran into DEMEE while working in an industrial paint shop. There, it didn’t just sit around in big barrels gathering dust—it played a key role in making paint apply smoother and dry evenly. When brushing paint on big metal structures or piping, nobody wants streaks or clumps. DEMEE helps keep things even and workable, bringing out the best in coatings for ships, bridges, and even backyard decks.

It also works well in cleaning products. I’ve seen it added to both heavy-duty degreasers and household sprays. DEMEE helps dissolve greasy residues from kitchen stoves and car engines alike. It cuts through tough gunk, but doesn’t leave a strong chemical odor, which becomes important when you’re wiping down surfaces you touch on a daily basis. Plus, it can help keep those solutions from drying out before you finish the job, which beats going back for more scrubbing.

Printer ink can feel like a scam sometimes, especially when a cartridge dries up fast or streaks across the page. DEMEE—being a good solvent—gets used in inks to prevent these headaches. It stops pigments from settling too quickly and keeps the ink flowing evenly through nozzles or onto printing plates. The difference is clear in the final print. Back in college, I worked in the campus print shop, and nothing sent the whole operation off the rails like a bad batch of ink that clogged up the printers. The techs would store the cartridges with a bit of DEMEE, and the difference in reliability became obvious pretty quick. Less waste, less downtime, better prints.

DEMEE steps up in the pharmaceutical world, too. A lot of creams or gels you buy at the pharmacy wouldn’t feel right without it. It acts as a solvent for ingredients that don’t like blending together. For folks blending topical solutions, whether in big labs or small pharmacies, this makes life much easier. I spoke to a pharmacist who once explained how DEMEE helped keep an antifungal cream from separating, which kept it just as effective on the hundredth use as on the first. When people rely on a medicine to work the same every time, this sort of reliability means something.

Not everything about DEMEE is sunshine, though. Some solvents have gained bad reputations for being toxic, polluting waterways, or causing health problems after many years of exposure. DEMEE doesn’t show the worst of these risks; it’s not as hazardous as some chemical cousins, but no one should splash it around carelessly or pour it down the drain. Gloves and good ventilation keep workers safe, and regular monitoring means workers aren’t at risk for headaches or other issues over time.

Finding safer alternatives or recycling cleaning solutions helps cut down on waste. Companies training workers with straightforward instructions, and switching to less harmful options when possible, keeps everybody safer. The chemical world is full of tools—used carefully, DEMEE keeps modern industries moving, without becoming the next big risk.

Most folks don’t bump into diethylene glycol methyl ethyl ether (DGME) on a grocery run. Yet, plenty of industries rely on it – from inks and paints to cleaners. If you tinker in a lab or manage manufacturing, you’ll cross paths with the stuff sooner or later. You might see it on safety data sheets, or maybe someone mentioned it after a spill. The chemical seems harmless; after all, it’s clear and doesn’t have a strong smell. That’s exactly why it can slip under the radar.

DGME can sneak past your nose and find a way into your body if you get careless. Breathing in vapors, letting it touch skin, or swallowing by accident — each path leads to health headaches. I remember my first glove-free lab job in college, a tiny splash from what looked like simple solvent turned my hands red and itchy for days. That mild irritation from a few drops took me by surprise, and DGME reacts in much the same way with skin. Extended contact leads to more intense irritation, headaches, and in rare cases, effects on the nervous system. None of that shows up as soon as you spill, which tricks people into thinking everything’s fine.

Dusty old posters still hang on the laboratory wall, showing folks with their sleeves rolled up, fiddling with flasks. Truth is, rolling up your sleeves just gives chemicals like DGME more landing space. Most companies now require gloves made from nitrile or neoprene. Latex fails in these situations since this chemical slips right through. Eye protection isn’t about looking smart, either. Once I saw a splash bounce right off a beaker into someone’s face shield and, honestly, watching him rinse his eyes in a panic sticks with you.

Keeping ventilation strong also makes a giant difference. If DGME vapors build up, headaches and dizziness soon follow. Simple fans don’t cut it. Installing fume hoods or working only in well-ventilated rooms prevents most issues before they start. Clean-up shouldn’t be an afterthought. Even if a spill looks easy to handle, using an absorbent and disposing of it as hazardous waste stops bigger problems from developing.

Training isn’t just a box to check off. People cut corners under pressure, or because they’ve worked with something “just like this.” DGME feels like a hundred other solvents, but assumptions cause trouble. Running through updated safety briefings and keeping material safety data sheets handy gives everyone a fighting chance. Teaching by showing, not just telling, sticks far better than any policy manual.

Labeling beats memory every time. Seeing clear hazard pictures tells even new folks what’s up. Lock cabinets keep DGME out of reach for those not trained to use it, especially in busy workshops with visitors or students.

You can’t stop people from making mistakes, but you can build workplaces where mistakes don’t turn into medical emergencies. The difference always comes down to respect for the chemical, not just its reputation. DGME offers plenty of value but only to people who treat it wisely. By building routines around solid gloves, splash-proof goggles, good air, and fast clean-up, handling chemicals shifts from a gamble to a shared responsibility.

Diethylene glycol methyl ethyl ether — sometimes called DEG MEE by chemists — brings a certain versatility to the table. This liquid flows clear and doesn’t announce itself with much of a smell. Folks who handle it notice its substance, not too light or heavy, and it leans just above water’s weight with a specific gravity around 0.98 at room temperature. Its boiling point rests near 194°C, so it stands up to a good deal of heat before vapor steam rises. Importantly, this chemical doesn’t rush to catch on fire; its flash point hovers near 85°C, so it won’t ignite on a whim in a typical workplace.

Solubility sometimes determines what role a chemical gets to play. DEG MEE mixes right in with water and most organic solvents, making it a strong ally in cleaning agents and inks. Imagine how water and oil just can’t seem to get along, but this compound bridges that gap. Drop some into an industrial formulation, and you typically end up with a more uniform blend every single time.

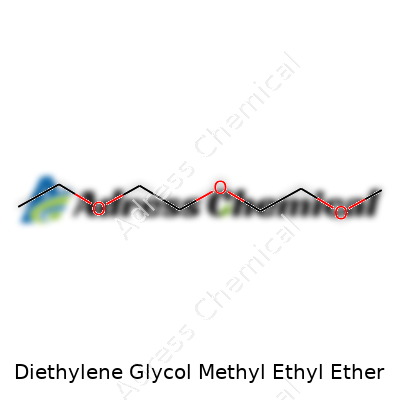

Chemically, DEG MEE sits in that family known as glycol ethers. Its molecular formula, C7H16O3, opens doors for flexibility. It resists quick breakdown under normal lab conditions. So, if you leave a bottle sealed in a storage room, you likely won’t come back to an unpleasant surprise. Its structure holds steady, dodging unwanted reactions unless strong acids or oxidizers show up.

The real-world chemistry of this compound finds importance in its low evaporation rate. Painting crews and printing factories value this trait. Slow evaporation gives them time to work inks and paints, helping color settle smoothly without pesky streaks or early drying issues. In cleaners, it digs deep into dirt and grease, carrying them away when rinsed with water. Degreasers made with DEG MEE often outperform old-fashioned soap, thanks to this deep penetration and stability.

Safety conversations matter once you step outside the lab. DEG MEE won’t explode, but its molecules enter the body just by breathing its vapor in high concentrations or through contact with skin. Some research ties repeated heavy exposure to organ stress. So, workplaces look to engineering controls like good ventilation and personal gear — gloves, goggles — to lower risk. You want these protections in place, not just a bottle sitting on the shelf with a warning label written in fine print.

Over time, concern has built up around glycol ethers in general. Agencies like the US EPA and Europe’s REACH program have issued guidelines for use, storage, and disposal. People who care about clean water watch out for spills, since chemicals like DEG MEE dissolve and spread rapidly. Quick containment and proper waste disposal, not just pouring down the drain, make a real difference in preventing harm to rivers and lakes nearby. Responsible companies now keep spill kits ready and train staff even before regulators ask for it. That hands-on approach goes a long way in keeping both people and the planet safer.

Experience on the industrial side shows that substitution sometimes gets complicated. Trying to simply swap DEG MEE for a safer or more natural ingredient often means trade-offs for performance and cost. The way forward seems to rest on better technology: more precise ventilation, improved process controls, and active worker training. If more factories commit to safer handling and clearer communication, many of the concerns tied to DEG MEE use and disposal can see noticeable improvement. Responsible practice beats quick shortcuts every time.

Stashing and shipping chemicals like Diethylene Glycol Methyl Ethyl Ether isn’t just a task for folks in lab coats; real lives ride on smart choices here. This solvent pops up in coatings, inks, cleaners, and a surprising number of manufacturing sites. My first round in an industrial supply warehouse taught me just how quickly a single mistake could shut down an entire operation. The clean, slightly sweet-smelling liquid doesn’t scream “danger,” but its hazards lean in quietly.

Leaving drums of this ether in a corner might sound easy, but the story never ends well. This chemical’s vapor carries a punch—one whiff in a poorly-ventilated room and headaches roll in. Fire hazard? Absolutely. Flammable liquids, especially ones that don’t advertise their risks with a strong odor, have a sly way of getting ignored. Keeping it away from heat sources plays a major part, and I’ve seen ancient boilers stashed right near chemical barrels more times than I can count.

Metal drums with tight seals stand as the base-level expectation here. You want containers that hold up against corrosion and leaks. Polyethylene works fine, though metal often gets the nod for long hauls. Moisture can sneak in, triggering toxic by-products over time, so those seals do double duty.

One of the best lessons I took from a plant manager: always label everything loudly and clearly. Mixing drums without knowing what’s inside turns a workplace into a dangerous guessing game. Periodic checks for rust, swelling, or leaks reveal the early signs of trouble that save headaches and, more importantly, lives.

Transport offers a fresh set of worries. Trucks and rail need secure tie-downs, open ventilation, and dedicated chemical transport certifications. The DOT and international regulators (like the IMDG code for sea freight) spell out rules for packaging, but I’ve watched plenty of haulers take shortcuts, banking on luck instead of preparation.

Accidents do happen, but strong protocols slam the risk way down. Absorbent liners under every drum stop a small leak from becoming an expensive—and hazardous—puddle. Proper temperature control really matters in hotter climates; I once saw a delayed shipment cook in the back of a truck, swelling drums nearly to bursting.

Emergency kits should travel with any load. Chemical-resistant gloves, respirators, spill containment socks get used a lot more than you’d think. Emergency contacts should sit where drivers and workers can see them in seconds, not buried in a glovebox. The little stuff—like making sure no forklift prong nicks a drum—stays underrated until the day crews have to clean up a spill.

Training sits right upfront. It never gets old to refresh teams through drills and walkthroughs, not just pamphlets. Real hands-on practice leaves everyone sharper. Tracking tools—barcodes or RFID—help keep tabs and make recalls easier. A simple digital record beats fuzzy memory any day.

Even big firms sometimes gamble with shortcuts, counting on routine to protect them. My experience says it pays more to sweat the details: clear labeling, airtight barrels, decent ventilation, and constant vigilance during shipments. Lax behavior drains trust fast, and people respond to leadership that sets the bar higher every time.

Diethylene Glycol Methyl Ethyl Ether—a mouthful, I know—shows up in labs and manufacturing plants across many industries. Being someone who’s spent hours worrying about what happens when two chemicals shake hands, I have learned that chemical compatibility rarely breaks the rules. At its most basic, this solvent dissolves a wide variety of substances. For anyone mixing chemicals or planning solvent swaps, this property matters a lot.

Many have asked: “Can I just pour this into my existing solvent blend?” The answer never sits comfortably at a simple yes or no. For me, working with glycol ethers comes down to understanding solvent polarity, water miscibility, and the elephant in the room—reactivity. Diethylene glycol methyl ethyl ether plays nice with water, alcohols, esters, and other glycol ethers. Industries exploit this for coatings, cleaners, and dyes. I remember working with a team that used this solvent to clean sensitive parts, appreciating how easily it blended with both polar and some non-polar solvents.

Not every mix works out. From my years handling chemical storerooms, there’s always a story about someone mixing things without double-checking. Diethylene glycol methyl ethyl ether resists reaction with most acids and bases under average conditions. Whether you’re trying to dissolve a powder or thin out a resin, its forgiving nature keeps it from creating dangerous byproducts in most settings. But forgiving doesn’t mean invincible. Pairing it with strong oxidizers can trigger unwanted reactions—in my experience, this is where trouble usually comes from. That’s not just textbook knowledge; I’ve seen solvents degrade or discolor unexpectedly, creating work for everyone on the shift.

In paints and inks, compatibility matters for transparency and drying. If you mix incompatible solvents, separation happens. This doesn’t just mess with appearances; the end product loses stability. A few years ago, a manufacturer I worked with had to recall a batch because residual solvents, ignored during formulation, led to product failures way down the line. That was a hard lesson about checking every ingredient’s compatibility, not just the main ones.

Material safety data sheets (MSDS) light the way here. They list what not to mix and identify known reactions. Industry databases cover many of these mixtures, but I never trust a table alone. I like to check for clues from suppliers and colleagues who have run similar blends before. In the lab, we sometimes started with small-scale tests to spot separation or cloudiness, which hint at deeper incompatibility. Even a few milliliters can reveal a world of trouble—or show that you’re on solid ground.

PPE and proper ventilation go a long way for safety, and compatibility guides decisions about storage—no mystery containers or unlabeled mixtures sitting around. I’ve seen what happens if a spill involves an unexpected reaction. Keeping a chemical inventory up to date prevents these scenarios. Training staff doesn't just mean reading the label, but understanding the ingredients hiding behind trade names. The right combination can boost productivity or save costs, but the wrong one wastes material and time, and risks health or safety.

Anyone working with diethylene glycol methyl ethyl ether benefits from looking past quick assumptions. Sure, compatibility looks great on paper for most mixtures, but process changes, trace contaminants, and new regulations can change what works. Listening to the wisdom of coworkers—especially those who have seen a few chemical surprises—trumps broad compatibility charts. Testing, careful review of documentation, and a dose of caution shape good decisions.

| Names | |

| Preferred IUPAC name | 2-ethoxy-2-(2-methoxyethoxy)ethanol |

| Other names |

2-(2-Methoxyethoxy)ethanol DEGEE Methoxy diethylene glycol Ethylene glycol, methyl ethyl ether Diethylene glycol monoethyl methyl ether |

| Pronunciation | /daɪˈɛθɪliːn ɡlaɪˈkɒl ˈmɛθəl ˈɛθəl ˈiːθər/ |

| Identifiers | |

| CAS Number | 1002-67-1 |

| Beilstein Reference | 04 01 02 05377 |

| ChEBI | CHEBI:81773 |

| ChEMBL | CHEMBL1377 |

| ChemSpider | 12210 |

| DrugBank | DB14183 |

| ECHA InfoCard | 03b2dbdb-8132-4c0e-b7a3-2fdcfbd0f9c7 |

| EC Number | Index No: 603-180-00-X |

| Gmelin Reference | 39942 |

| KEGG | C19635 |

| MeSH | D018378 |

| PubChem CID | 8176 |

| RTECS number | KL5950000 |

| UNII | 0FF900F1SR |

| UN number | UN3082 |

| CompTox Dashboard (EPA) | DTXSID0025024 |

| Properties | |

| Chemical formula | C7H16O3 |

| Molar mass | 134.18 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 0.983 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.54 |

| Vapor pressure | 0.017 mmHg (20°C) |

| Acidity (pKa) | 14.78 |

| Basicity (pKb) | 7.46 |

| Magnetic susceptibility (χ) | -8.29×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.415 |

| Viscosity | 2.4 cP (25°C) |

| Dipole moment | 2.96 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 374.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -4294.7 kJ/mol |

| Pharmacology | |

| ATC code | D02AX |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P305+P351+P338, P337+P313, P370+P378, P403+P235, P501 |

| Flash point | 94 °C |

| Autoignition temperature | 190 °C |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 (oral, rat): 5,660 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 3,540 mg/kg |

| NIOSH | UB2975000 |

| REL (Recommended) | 10 ppm (45 mg/m3) |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Diethylene glycol Diethylene glycol methyl ether Diethylene glycol ethyl ether Ethylene glycol Ethylene glycol methyl ether Triethylene glycol dimethyl ether |