Folks in the chemical world have chewed over glycols and their ethers since late 19th-century labs figured out how to distill, refine, and play with them. When diethylene glycol diethyl ether, also called "DEGDEE," first landed on the scene, it was during an era obsessed with expanding the toolkit for everything from paint blending to advanced organic syntheses. Traditional glycol ethers—like ethylene glycol monoethyl ether—showed up first, then scientists started stringing together longer chains, and their interest in the byproducts grew. DEGDEE found its niche as people realized it could pull off feats its smaller cousins couldn't. It often quietly starred in research, helping dissolve resins, power up reactions, or reduce evaporation. Over time, DEGDEE’s reputation as a reliable, multitasking solvent solidified, particularly among folks working in coatings, inks, and electronics.

DEGDEE shows up as a clear, colorless liquid that doesn’t care much about the limelight. Its role is unglamorous, but critical. Coatings, cleaning products, electronics, even hydraulic fluids use it. You’ll find the stuff humming away in the background, improving performance without stealing the show. It sports a slight, ether-like smell—mostly neutral, but you always know it’s in the room once you’ve worked with it. Some folks might call it "Diethylcarbitol," or label it under trade names that sound like combo words only chemists could love. But at its core, it’s DEGDEE, the strong, silent type in the solvent line-up.

DEGDEE weighs in with a molecular formula of C8H18O3 and carries a molecular weight just north of 162. Its boiling point—set at around 220°C—outpaces a lot of run-of-the-mill glycol ethers. This higher boiling point turns out to be the secret sauce for formulations that can’t let everything flash off too quickly. Folks notice its low viscosity—easy to pour, easy to blend. It’s got good miscibility with water and organic solvents, and, crucially, it won’t evaporate at the drop of a hat. Its flashpoint hovers around 100°C, making it less flammable than many options, but not forgiving enough to be sloppy around. DEGDEE doesn’t gunk up or polymerize easily, so it never leaves messy residues.

You won’t get far without good labeling. Labels read "Diethylene Glycol Diethyl Ether" or "DEGDEE" by law, but the more technical details—the ones real users care about—show boiling point, purity (usually 99%+), density near 0.95 g/cm³, and refractive index. Manufacturers print these on material safety data sheets along with hazard codes like “Harmful if swallowed” and flammable liquid warnings. It might be marked UN 1993 or slip under other regulatory radar, but any operation worth its salt will print the standard batch number, origin, and hazard warnings prominently.

Process chemists prepare DEGDEE by reacting diethylene glycol with ethanol in the presence of an acid catalyst. This classic etherification process strips off water and joins the glycol and ethanol units, producing the right ether bonds. Most industrial setups distill the product several times to push up purity and yank out unreacted starting materials. Earlier methods often left more impurities, but today’s reactor setups run tighter, control heat and pressure better, and catch byproducts, boosting yields and keeping environmental headaches in check.

DEGDEE gets involved where it counts in reactions that need a polar aprotic solvent. Unlike water, it won’t donate protons or introduce side products, which matters for nucleophilic substitution and certain coupling reactions. Chemists sometimes modify it to produce more functionalized ethers, stretch out the chain, or attach new groups, making even more tweakable solvents. On the whole, it stays pretty inert under standard conditions, but at higher temperatures or with strong oxidizers, its molecules can break down and trigger further reactions. Labs tend to stash it in glass or stainless steel vessels—never in plain plastic—since incompatibilities tend to show up with certain polymers.

The chemical world loves giving one compound half a dozen names. DEGDEE often pops up as "Carbitol Ether DE," "2,5,8,11-Tetraoxadodecane," or under older catalog names from companies like Dow or BASF. Each supplier slaps on a new product code, but take a peek at the fine print, and it's easy to spot the diethyl glycol backbone. Knowing your synonyms pays off—not every shipment labeled “diethyl carbitol” came from the same process or lives up to the same spec, making it smart to check CAS numbers (112-36-7).

It pays to be careful with DEGDEE. Swallowing even small amounts causes kidney and nervous system issues, so good operations keep this stuff locked down, gloves on, and eye protection ready. It’s less volatile than a lot of solvents, but spills still need prompt cleanup. Fume hoods or open-air workspaces cut down exposure. Labels show wavy pictograms—exclamation marks, flammable liquid icons. Staff should always have access to eyewash stations, spill kits, and up-to-date MSDS sheets. Some places don’t appreciate how quickly glycol ethers soak through latex gloves, so nitrile or butyl gloves prove a smarter choice. Training on safe storage—low light, good ventilation, cool temperature—protects people and prolongs shelf life.

Industries turn to DEGDEE for its unique blend of polarity and staying power. The coatings field relies on it during paint formulation or pigment dispersal, since it holds resins in solution for longer and prevents cracking during drying. Ink makers appreciate its slow evaporation—especially in flexographic or gravure systems. Electronics manufacturing puts it to work during cleaning and circuit board prep, as it wipes away residues without frying components. With hydrophobic and hydrophilic ends, DEGDEE blends with a wide range of diluents or surfactants. Even the perfume and flavor sector occasionally dabbles with it for capturing volatile notes during extraction. You won’t see it splashed across product labeling, but there it is, quietly shaping a thousand final results.

Labs across universities and companies eye new uses for DEGDEE. I’ve seen research groups swap it for more toxic solvents in hopes of getting the same results in reactions that can’t afford water or high acidity. Green chemistry efforts also explore recycling DEGDEE after its first use—distilling and reusing it in closed-loop setups—minimizing waste. Teaming up with other solvents, it sometimes acts as a cosolvent, letting researchers dissolve tough polymers or stir up new drug formulations. Add in the constant push for safer, more biodegradable solvents, and DEGDEE often sits at the center of projects trying to replace old-school, harsh chemicals in adhesives, electronics, or specialty inks. Students, postdocs, process managers, all get a crack at working with it, searching out new blends, and running head-to-head comparisons against traditional glycol ethers.

Scientists have dug deep into the toxicity of DEGDEE, especially after scares with other, shorter-chain glycol ethers. Animal data shows it doesn’t turn toxic as easily as its close kin, but breakdown products inside the body—mainly ethanol and glycol-based metabolites—bring their own risks. Its low acute toxicity sometimes lulls users into carelessness, but repeated skin exposure dries and irritates, and lab animals on high doses show kidney and liver stress. Regulatory agencies haven’t banned it, but product safety panels keep tabs on workplace exposure, recommending strict limits in confined spaces. Environmental releases create issues for aquatic organisms—DEGDEE lingers long enough to disrupt water quality if you spill gallons at a time. For the chemists, the lesson always reads the same: gloves on, goggles down, and never assume “less toxic” means “no risk.”

The outlook for DEGDEE lines up with industrial trends: lower toxicity solvents, better recyclability, and performance at higher temperatures. New coatings, battery systems, even some advanced pharmaceutical production protocols could use a solvent with properties right in DEGDEE’s sweet spot. Research keeps pushing for glycol ethers that break down quicker in the wild but still hold up in the reactor, and DEGDEE finds itself right in the thick of that balancing act. I’ve seen interest from startups focused on green tech, especially electrolyte systems for safer, longer-life batteries, and from inkjet printer companies that want to stretch shelf life while cutting out the nastier VOCs. If regulations keep pushing for lower workplace exposures, producers may clean up processes even more, pushing for grades with even tighter controls on byproducts. In a chemical landscape always hungry for one more edge, DEGDEE still has cards to play.

People walk past chemical warehouses every day without giving chemicals a second thought. Most folks don't know about diethylene glycol diethyl ether, or DEGDDE for short, yet it sits behind the scenes in more products and processes than folks realize. Having worked in a small specialty chemical lab, I’ve seen DEGDDE juggle multiple hats all at once. It doesn’t seek the spotlight, but it keeps a lot of industries moving.

You ever painted a room and wondered why the stuff goes on so smooth? DEGDDE acts as a bridging solvent in both water-based and solvent-based paints and inks. It helps certain resins and colorants dissolve and stay mixed. Back in that lab, we once dealt with a batch of ink that blobbed up without the right co-solvent. Adding DEGDDE made all the difference. Paints dry evenly, inks print sharp, and coatings aren’t patchy. It helps keep pigments and additives dispersed so they do what they’re meant to do.

Some might expect every pill or cough syrup to use only fancy ingredients, but pharmaceutical experts rely on hard-working solvents to deliver medicine reliably. DEGDDE sometimes appears as a carrier in topical creams, ointments, and a few injectable formulas. Its low toxicity at industrial grades makes it a solid pick for dissolving stubborn compounds. Drug companies keep a close eye on what goes into a medicine, and DEGDDE’s flexibility for dissolving both oily and watery ingredients makes it valuable.

Gadgets and batteries need solvents that won’t corrode their guts or short circuit things. DEGDDE’s stability helps keep electronics clean during production and testing. It also gets used to formulate electrolytes for batteries, especially in labs searching for the next big jump in battery life. Battery makers need solvents that won’t break down after a few months. I chatted with an engineer who said any slip in purity or reactivity could knock months off a battery’s usable life.

Some industrial cleaning blends pull off impressive tricks—degreasing engines, stripping inks, or prepping metal for painting. DEGDDE’s solvency and low evaporation rate mean it sticks around long enough to dissolve tough grime, versus evaporating instantly like lighter solvents. It works faster than basic soap and water, but not so aggressive that it melts plastics or cookware. We once tested it during a spindle-cleaning job, and it cut through the oil slick without releasing harsh fumes.

The usefulness of DEGDDE doesn't erase its risks. Handling raw chemicals always calls for gloves, good ventilation, and disposal know-how. Stories about toxic substitutes sneaking into cough syrup or contaminated solvents harming workers show why transparency is everything. Regulators set exposure thresholds for a reason. Anyone using DEGDDE in bulk should treat it like any flammable or toxic liquid—store it well, use it properly, and don’t let it near drains or food.

Some ink and paint manufacturers have started chasing green chemistry. Reducing hazardous emissions matters, and sometimes safer alternatives or water-based formulas lower the risk. Switching isn’t always quick or cheap, but those efforts keep people and the environment from paying for shortcuts. Conversations with industry insiders suggest the hunt for better solvents never stops, but for the jobs that DEGDDE does well, few substitutes have caught up yet. The spotlight rarely lands on working-class solvents, but without them, all sorts of industries would struggle to perform the way customers now expect.

Most folks who work in labs have met chemicals like diethylene glycol diethyl ether. Maybe you spotted it on a bottle with a handful of hazard pictograms or a pile of fine print. For many, it just feels like another day, another solvent. But experience teaches you to stop and actually consider these chemicals, especially ones with “glycol” in the name. The label doesn’t always tell you what it really takes to stay safe.

You don’t have to look far for news about solvent accidents. Diethylene glycol diethyl ether flows clear and odorless, so spills go unnoticed until it’s too late. Most people don’t realize that, like so many ethers, it can easily pass through gloves and right into your bloodstream. Longer skin contact brings headaches, dizziness, even organ damage over time. Even if you avoid direct touch, breathing in its vapors can irritate airways and cause serious problems with prolonged exposure. And this isn’t just theoretical—plenty of lab technicians and manufacturing workers have ended up with chronic symptoms after regular handling of these chemicals.

Solvents play a big role in research and industry, but that tends to make us less cautious around them. Just because diglyme or similar compounds keep engines or drug molecules running smoothly doesn’t mean careless handling won’t do harm. The fact is, the human body can only take so much, and diethylene glycol diethyl ether isn’t gentle, regardless of how routine its use might seem.

Manufacturers write safety data sheets for a reason, but my own time working in shared university labs taught me that few read much beyond the storage requirements. The moment someone spilled a bottle and tried to mop it up with bare hands, the sharp, stinging smell lingered in the room all week, and we ended up filing incident paperwork.

Real safety comes from a bit more effort. Chemical-resistant gloves—preferably nitrile or butyl—do a much better job than standard latex. Good goggles protect against accidental splashes. Decent ventilation matters too; fume hoods are not just decoration. If you get any on your skin, immediate washing with lots of water beats hesitation.

Training helps, but sometimes day-to-day culture matters more. People should check their habits: are containers properly labeled, is the gear close at hand, do folks skip gloves for “quick tasks?” These little things stop small mistakes from turning into months of chronic headaches, or worse.

It pays to rethink process design. Engineers and managers should look for ways to minimize direct handling. Closed transfer systems for bulk solvents limit exposure, just as good spill containment plans reduce accident fallout. I’ve seen talented chemists set up stations where everything—PPE, first-aid, waste bins—sits within reach of their main work. This cuts down on bad improvisation and sharpens habits.

There’s always pressure to work faster or cut corners when budgets run tight. But skipping safety steps with toxic solvents eats up time down the road—cleanups, paperwork, medical bills, lost workdays. Diethylene glycol diethyl ether isn’t the worst chemical you’ll meet, but it’s far from harmless.

Anyone handling chemicals long-term should know what stands between safe use and chronic harm. One accident can set off a lifetime of kidney or nerve problems. As someone who’s handled more than a few mystery bottles, I’ve learned safety makes a lot more sense than regret. The best way to keep diethylene glycol diethyl ether harmless is to treat it like it isn’t.

Diethylene Glycol Diethyl Ether, known by people in labs as DEGDDE, finds its way into all sorts of applications. Solvents like this one slip into paints, coatings, batteries, and even pharmaceuticals, mostly because of how well they can dissolve stubborn substances. While the science sounds neat, dealing with this compound out in the real world can bring headaches if the right steps get ignored.

I've seen storage rooms turn into minefields by ignoring heat. DEGDDE’s flash point sits at about 107°C (225°F), which means it won't burst into flames without a pretty high heat source, but hot weather or careless storage raises the risk fast. Flammable liquids belong in cool, well-ventilated spaces out of direct sunlight. Stacking barrels near heaters, or even next to sunny windows, sets you up for problems that nobody wants. Keep a thermometer in your storage area—don’t just guess whether it feels cool enough.

Chemicals like these ask for sturdy containers. I had a colleague lose a month’s work—and put themselves in danger—just from a cracked drum that nobody double-checked. Choose containers made from materials that resist strong solvents, such as HDPE (high-density polyethylene) or metal drums lined for chemical resistance. These barrels shouldn’t sit directly on the floor, especially on concrete, since even a few drops can chew through weak spots, ruin floors, or create breathing hazards.

Walk into any warehouse, and you can pick out the safe spaces by the way the air moves. Good ventilation matters, not just for comfort, but to avoid a buildup of vapor. DEGDDE doesn’t stink up a room in seconds, but invisible vapors add up and take a toll on lungs and nerves. Exhaust fans and open pathways keep air moving. Masking the smell with scents or sprays won’t fix the hazard itself.

I’ve found too many old cans in back corners with faded labels. DEGDDE isn’t something you want to guess about, so the rule is clear: never let containers go unmarked. Include the correct chemical name, date received, hazard icons, and emergency contact numbers. This basic step saves time during audits, but more importantly, can save lives if an emergency rolls in.

Stocking chemicals side-by-side may look tidy, but some pairings spell trouble. Flammable solvents like DEGDDE stay safest far from oxidizers, acids, and bases to avoid chain reactions or fires. Get a chemical storage chart and tape it somewhere prominent—sometimes all it takes is reminding someone before they put the wrong jug in the wrong place.

Safety glasses, gloves made for solvent resistance, and spill kits always need to be close at hand. I keep an eyewash station inspected and working, not for show, but because once-in-a-career accidents do happen. Fire extinguishers rated for chemical fires and regular drills for everyone handling DEGDDE build habits that make a difference in real emergencies.

DEGDDE isn’t unusual in requiring careful storage, but it doesn’t cut anyone slack either. Take temperature, container choice, labeling, ventilation, and separation seriously. Attention to these details pays off in safe workplaces and healthy people, which matters more than any cost saving or space squeezed out of a crowded storeroom.

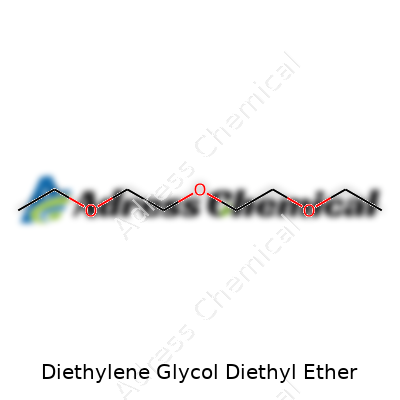

Diethylene Glycol Diethyl Ether, known to some as Ethos, doesn't pop up in most dinner conversations, but its story says plenty about the tug and pull between chemistry and everyday life. This clear liquid shows up in the backgrounds of labs that focus on solvents, coatings, and inks. Its formula, C8H18O3, points to its backbone: two ethylene glycol groups bridged with ether bonds and extra ethyl groups on the ends. These details shape nearly everything about how this compound behaves.

Pour some of this liquid into a glass beaker, and you’ll get a clear, colorless fluid that looks a lot like water. The resemblance stops there. What struck me most in my days around research benches is the distinct smell these glycol ethers carry—just sweet enough to set them apart from your typical alcohols. Its boiling point hovers around 192°C, which makes it stable even in warm environments. Oddly, it doesn’t freeze easily either, holding out until about -70°C. Its low viscosity means you’re not stuck scrubbing out sticky residue. It weighs a bit more than water, so it settles quickly if you spill some among lighter solvents.

One property that keeps it useful: strong solubility. It mixes with water, alcohols, and many organic solvents. That mixing power drives much of its work in industrial settings, especially where stubborn resins and pigments need a gentle nudge into solution.

Here’s where this compound earns its place on the shelf. The presence of ether and alcohol groups means it can tolerate strong acids and bases without breaking down too fast. It avoids wild reactions with air or most metals—an advantage if you need a stable medium for mixing and dissolving. In my time blending inks, I saw how its chemical resilience helped keep final products consistent, batch after batch.

Yet, that stability invites a bit of caution. Since it doesn’t break down easily on its own, spills can linger. And if someone runs it through high temperatures with strong oxidizers, toxic byproducts surface—so care around heat and storage is real.

The properties of this glycol ether bring both help and headaches to workers and manufacturers. As a solvent, it can quietly creep through skin, especially if gloves are thin or torn. I learned quickly not to skip proper protection, since overexposure sometimes causes headaches or bigger health complaints for those unlucky enough to spend long hours near open containers. Regulatory boards in Europe and the United States catch onto these risks by setting lower exposure limits.

On the flip side, safer chemicals often struggle to dissolve stubborn ingredients as well as Diethylene Glycol Diethyl Ether. This puts paint producers and ink makers in a bind, balancing worker safety and production requirements. Swapping out this solvent means someone invests extra time testing new blends or designing fume extraction systems strong enough for large rooms. I’ve watched small shops duck these changes because costs land hardest on the folks who earn the least.

There’s talk in research labs about new solvent options made from plant-based alcohols. While none have matched this glycol ether’s full package of performance yet, smarter chemical engineering might narrow the gap. It takes more than a law to push for better choices; it takes honest conversations between workers, managers, and chemists. Real improvement means bringing safer, greener compounds into reach—without forcing shops to close their doors.

Plenty of labs and factories reach for diethylene glycol diethyl ether—often known as DEGDDE—when they need a solvent. It dissolves all sorts of things, helps with reactions, and pops up in paints, coatings, and even pharmaceuticals. People might think a chemical like this fits with everything. In reality, mixing one chemical with another isn’t always simple or safe.

Ask any chemist or technician who has cleaned up a spill or seen a reaction go wild: most chemicals rarely play nice with everything on the shelf. DEGDDE shares this trait. Its ether groups and glycol backbone give it good solubility in water, alcohols, esters, and even some hydrocarbons. Scientists often lean on it because it can bridge the gap between water-loving and oil-loving substances.

But compatibility never means “total safety.” DEGDDE reacts with strong acids like sulfuric or hydrochloric acid, and it can break down after long contact with bases, releasing smaller volatile ethers or causing builds up of pressure. Mixing with powerful oxidizers like potassium permanganate or nitric acid causes real hazards. One mistake mixing in a rush or skipping a step in the process can turn a clever solvent into a recipe for disaster.

I’ve watched how fast a well-planned process changes when someone forgets to check that chart in the lab. Once, a solvent container set too close to bottles of bleach and acids led to emergency alarms and a full evacuation at a place I worked. People tend to underestimate what a spill means until a nose gets stung by harsh vapors or warnings from the hiss of a reaction that shouldn’t happen. DEGDDE brings low toxicity compared with some of its relatives, but that makes it easier to treat too casually.

Direct skin contact causes irritation, and even though respiratory injury is rare, nobody needs to gamble with fumes. Fire is another danger. Its vapors catch flame with enough spark or heat—something often missed when people focus only on liquid spills. In storage, I saw some of the safest results with strong labeling, separate shelves for oxidizers, acids, and bases, and workers who got into the habit of checking compatibility lists before pouring or mixing anything.

A common solution is spreading real training. Talking through “what-ifs” in the shop or lab reaches people more than dry safety posters. I learned early to trust both the printed data sheets and my own nose when something smelled off or reacted strangely. People should have quick access to compatibility charts and clear storage bins.

It helps to insist on procedures that slow things down—like two-person checks on chemical mixes, or basic spill kits kept where spills are likely. At larger plants, automated systems stop pumps or seal containers if heat or gas builds up from a reaction. Even in small workspaces, labeling secondary containers stops guesswork. Asking questions and taking an extra second to double-check beats any shortcut. With DEGDDE, just like other solvents, confidence comes not from assuming compatibility but from taking real steps to make sure every mix is safe—for people, for equipment, and for the planet.

| Names | |

| Preferred IUPAC name | 3,6-Dioxa-1,8-octane diethyl ether |

| Other names |

DEGDEE Diethylene glycol diethyl ether Ethyl diglyme 3,6-Dioxa-1,8-octane diethyl ether Diethyl diethylene glycol Diethylcarbitol |

| Pronunciation | /daɪˈɛθiːliːn ˈɡlaɪˌkɒl daɪˈɛθɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 112-36-7 |

| Beilstein Reference | 1209287 |

| ChEBI | CHEBI:40075 |

| ChEMBL | CHEMBL137606 |

| ChemSpider | 11121 |

| DrugBank | DB14035 |

| ECHA InfoCard | 100.003.363 |

| EC Number | 203-919-7 |

| Gmelin Reference | 8287 |

| KEGG | C19576 |

| MeSH | D007938 |

| PubChem CID | 8178 |

| RTECS number | KK9275000 |

| UNII | H9P7H348HD |

| UN number | UN1161 |

| CompTox Dashboard (EPA) | urn:C961896 |

| Properties | |

| Chemical formula | C8H18O3 |

| Molar mass | 178.27 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | mild, ether-like |

| Density | 0.914 g/cm3 |

| Solubility in water | miscible |

| log P | 0.56 |

| Vapor pressure | 0.05 mmHg (20 °C) |

| Acidity (pKa) | Acidity (pKa): ~15.1 |

| Basicity (pKb) | 1.91 |

| Magnetic susceptibility (χ) | -9.68×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.404 |

| Viscosity | 1.7 mPa·s (20 °C) |

| Dipole moment | 1.02 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 395.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -635.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4565.7 kJ/mol |

| Pharmacology | |

| ATC code | D01AE24 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P210, P280, P305+P351+P338, P337+P313, P370+P378 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 77°C (171°F) (Closed cup) |

| Autoignition temperature | 215 °C |

| Explosive limits | 1.5% - 10.1% |

| Lethal dose or concentration | LD50 (oral, rat): 7,460 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral (rat): 8570 mg/kg |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Diethylene Glycol Diethyl Ether: Not established |

| REL (Recommended) | 2 mg/m3 |

| Related compounds | |

| Related compounds |

Ethylene glycol diethyl ether Diethylene glycol dimethyl ether Triethylene glycol diethyl ether Diethylene glycol dibutyl ether Diethylene glycol monobutyl ether |