Dibutyl adipate keeps a surprisingly low profile for a chemical with as many roles as it has. People started making it in the early 20th century, not long after scientists figured out how to synthesize esters reliably. As demand grew for plasticizers that didn’t make plastics brittle, chemists turned to esters made from dicarboxylic acids and alcohols. In this case, mixing butanol with adipic acid gave rise to dibutyl adipate, and from there, the textile, plastics, and cosmetics worlds found a reliable workhorse. The story here isn’t one of flashy invention, but of practical chemistry meeting everyday industrial needs—dibutyl adipate stuck around because it worked well and was easy to scale up.

Dibutyl adipate shows up most often as a clear, oily liquid. It doesn’t have much of a smell, which suits it for cosmetics and skincare products. Unlike many other chemicals of similar character, it doesn’t make things sticky or overly greasy, which gives it a leg up among options for personal care. Its fat-soluble nature lets it mix into ingredients that aren’t water-based, giving manufacturers flexibility. It’s not an everyday household name, but it hides inside sunscreen, flexible plastics, nail polishes, even some inks and lubricants.

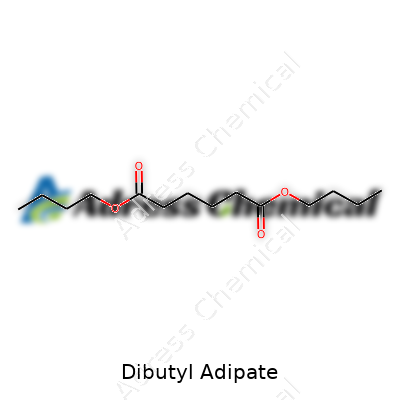

Look at the chemical formula—C14H26O4—and you get a sense of why it’s so versatile. Each molecule has two butyl chains tied to an adipic acid backbone, so the compound stretches nicely across oil-based and synthetic materials. Dibutyl adipate sports a boiling point around 340°C, and it won’t light on fire easily thanks to a flash point of roughly 174°C. You’ve got something denser than water, yet still light enough to flow well, with low vapor pressure so it doesn’t evaporate in the blink of an eye. This chemical won’t dissolve in water, but it blends smoothly with a wide swath of organic solvents.

Manufacturers pay close attention to product specs because dibutyl adipate needs to stay pure for technical uses. A decent sample runs above 99% purity, sometimes closer to 99.5% for the pickiest industries. Water content stays under 0.2% by weight, and acid value hovers well below 0.1 mg KOH/g, which keeps unwanted reactions in check. Labels adopt international standards, listing “dibutyl adipate,” “di-n-butyl adipate,” or its CAS number, 105-99-7, for easy identification. Those handling the chemical count safety icons and hazard statements as required by GHS and REACH, ensuring no step in the supply chain gets overlooked.

Chemists turn to esterification to make dibutyl adipate. The recipe calls for adipic acid and butanol, cooked together with a small amount of acid catalyst. The system gets heated under reflux, squeezing water out as the strength of the acid presses the two building blocks together. Modern factories often recover and recycle the butanol and catalyst, keeping efficiency high and waste low. Once finished, technicians wash out impurities and dry what’s left, reaching the purity levels preferred by plastics and cosmetic makers.

Nobody stops at the first reaction. Dibutyl adipate remains stable under the right storage, but with enough heat or strong acid or base, it breaks back down into its original components. Industrial users value its resistance to hydrolysis—water doesn’t split it apart easily—but over time in the presence of strong bases, factories can reclaim butanol and adipic acid. Its ester group stands out as a handle for later chemical transformations, opening doors to specialty applications. Sometimes formulators tweak the molecule’s properties by mixing it with other ester plasticizers, chasing that perfect balance between flexibility and stability.

In catalogs and MSDS forms, dibutyl adipate pops up under several names. You’ll see “di-n-butyl hexanedioate,” “DBA,” or the original trade names coined by U.S. and European suppliers decades ago. Synonyms like “1,6-hexanedioic acid, dibutyl ester” clarify the structure, which helps customs and regulatory staff keep paperwork straight. All of these names point to the same slippery, colorless liquid hiding in spray cans, lotions, and sunblocks.

Manufacturers can’t ignore worker safety, so established guidelines for exposure sit on every table in the plant. Dibutyl adipate doesn’t have the alarming toxicity of some older plasticizers—think phthalates—but careful handling still makes sense. Prolonged skin contact might cause mild irritation, and breathing in its vapors in high concentrations could dry out mucous membranes. Gloves, safety glasses, and splash-proof aprons get issued to keep technicians comfortable. Storage involves well-sealed drums kept away from heat and open flames. Every plant follows local frameworks like OSHA and international rules from GHS, backed by routine training sessions for anyone handling the chemical.

Its real-life impact shows up in many forms. Manufacturers pick dibutyl adipate for flexible PVC in wires and cable sheathing since it keeps plastic soft without breaking down quickly. In personal care, it carries sunscreen filters and fragrances deep into the skin, then evaporates slowly to leave behind the desired effect. Some ink makers add it as a slow-drying agent; textile finishers rely on it to keep fibers smooth and glossy. Machine shops have used it as a light lubricant, its low viscosity making it slip between tight-fitting metal parts. This adaptability stems from its balance of solubility, volatility, and chemical stability.

Scientists still dig into dibutyl adipate’s mechanics, trying to predict performance in new polymers or unexpected temperature swings. Research groups want biodegradable plasticizers for single-use plastics, and dibutyl adipate’s structure offers creative starting points. Cosmetic chemists aim to swap out legacy ingredients with less environmental baggage, so they run trials to spot how dibutyl adipate interacts with natural oils, preservatives, and colorants. A steady trickle of journal articles targets molecular tweaking—swapping butyl for longer or branched chains, or fusing additives onto the adipate backbone for better UV resistance or lower migration into neighboring materials. Regulatory agencies test it in blends and concentrates to document every behavioral quirk.

Toxicologists stay busy mapping dibutyl adipate’s footprint in the environment and the body. Most evidence points to low acute toxicity in animals and people, a relief given its broad use. Long-term exposure research doesn’t turn up strong links to endocrine disruption or reproductive harm—one reason regulators grant it approvals in consumer goods, if kept under set concentration limits. Still, regulators like the European Chemicals Agency require ongoing monitoring, especially for applications linked to children’s products or direct food contact. Some animal studies looked for chronic effects at very high doses, rarely turning up more than liver enlargement or minor weight changes with extreme, prolonged intake. Industry watchdogs err on the side of caution, calling for reduced skin exposure when handling in bulk.

Dibutyl adipate doesn’t rest on its history; it stands at the edge of new applications with every year. Pressure grows to find safer, greener solutions, and its chemical backbone gives researchers an adaptable puzzle piece—they can swap out one chain or tweak production to minimize waste. As plastics markets shift toward biodegradable solutions, and as the care product industry roots out ingredients under regulatory or public scrutiny, dibutyl adipate’s forgiving structure offers an advantage. Advances in green chemistry may one day replace even dibutyl adipate, but for now, chemists and industrial engineers see a challenge: stretch the life of this old workhorse by squeezing new benefits out of its core design.

Dibutyl adipate sounds like a chemical out of a high school textbook, but for folks in cosmetics, plastics, and even agriculture, it's something you bump into more often than you’d think. This stuff works as a plasticizer, making plastics flexible instead of brittle. You’ll spot it lurking in a bunch of skin creams, sunscreen, and nail polish, too. It’s one of those helpers that rarely gets named but does a lot of heavy lifting.

I’ve heard complaints about lotions feeling greasy or sunscreen refusing to soak in. A cosmetic chemist friend of mine once explained that dibutyl adipate acts like a sort of middleman between the oily parts and the watery parts of a formula. Because of this, it helps creams and gels spread more smoothly. If a sunscreen melts away into your skin and leaves no trace, there’s a fair chance dibutyl adipate played a part.

Some plastics, especially ones used in cables or car interiors, would crack fast without additives to keep them bendy. This ingredient lends the squish and stretch that children’s toys and phone chargers need to survive life in a bag or pocket.

I like knowing what’s inside a product before putting it on my skin. Facts from the Cosmetic Ingredient Review and European Chemicals Agency give dibutyl adipate a good bill of health when used as intended. Scientists checked, and the stuff doesn’t seem to irritate skin in practical concentrations. You still won’t find people pouring it on open wounds, but as things stand, it compares favorably to other common plasticizers that have run into health or environmental issues.

It’s important to bring up that countries like the United States and those in Europe keep a close eye on this ingredient. Regulatory agencies review new studies every few years. Any concerns, and companies have to reformulate their products. Transparency around ingredients helps everyone make smarter choices.

Talking about plasticizers means asking how they fare out in the world once we’re done with the bottle or toy. Dibutyl adipate breaks down in the environment faster than a lot of legacy plastic additives. That counts for something, though nothing in chemical manufacturing comes risk-free. People can push for more research, greener chemistry, and stricter recycling measures to lessen the load on soil and waterways.

Manufacturers might start using plant-based alternatives one day, but the switch won't happen overnight. Plant oils and safer synthetic chemicals still cost more and sometimes don’t quite match up in performance. The consumer has a say too: supporting brands that disclose ingredients and commit to eco-friendly production sends a message up the chain.

As someone who’s used everything from vintage electronics to the latest sunscreen, I’ve watched ingredients lists change and grow. Dibutyl adipate doesn't grab headlines, yet it plays its part in keeping modern products comfortable and reliable. Staying informed about what goes into everyday objects, asking questions about sustainability, and pushing for better practices will make a difference in the long run. Facts give us the power to choose—and to nudge companies toward safer, smarter solutions.

Dibutyl adipate lands in plenty of products sitting in medicine cabinets and bathroom shelves. This ingredient keeps creams smooth and makeup easy to spread. Turn over bottles of sunscreen, lotion, or even some bug sprays—dibutyl adipate often shows up in the fine print. Brands pick it because it gives formulas a lightweight feel on the skin and acts as a handy plasticizer in nail polishes.

The safety talk about dibutyl adipate starts with solid research. The Cosmetic Ingredient Review (CIR) Expert Panel checked out the bodies of work on this compound and gave it the green light for use in cosmetics. Toxicology reports—studies looking for irritation, allergies, and sensitivity—showed minimal cause for worry. In most cases, skin doesn’t show irritation unless someone has a unique sensitivity to almost anything that touches their face or hands.

Europe, known for tight cosmetic regulations, also allows it. Safety groups in the U.S., including the Food and Drug Administration, haven’t issued warnings about skin exposure. Most health experts agree: using products with typical concentrations of dibutyl adipate doesn’t increase the risk of health problems for most people.

Spending years in a dermatology practice, I saw busy parents, hair stylists, and makeup artists using creams and cosmetics daily. Allergic reactions get more notice than they should thanks to the rare stories that pop up online. From my direct interactions and feedback, few reactions trace back to dibutyl adipate. I can count on one hand the number of times I saw a rash or skin discomfort possibly linked to this ingredient, and those cases cleared up after switching to different products.

The chemistry works for nearly everyone, but outliers exist. Someone dealing with eczema, rosacea, or advanced allergies lives with a different rule book. Skin tests show no widespread patterns of dibutyl adipate causing flare-ups, yet a patch test always helps before new products hit sensitive skin. Fragrance and preservatives trigger more complaints than this base ingredient.

Questions about long-term buildup matter, especially since most users can’t track every item they apply. Current studies cover weeks and months, rarely many years. Still, animal and lab test data point away from worrying cumulative risks when used as directed. Scientific journals covering dermal absorption show that the body doesn’t hang on to dibutyl adipate for long—metabolism takes care of it.In the short term, people with healthy skin and no specific allergies can trust the research. For anyone juggling chronic skin conditions, it’s worth chatting with a specialist before loading up on new products.

Consumers looking for the safest bet often want simple ingredient lists. Reading labels and sticking with brands that carry out extra sensitivity checks bring peace of mind. For those who work with skin products all day—salon workers, medical caregivers—a patch test on a small area helps spot odd reactions early. Personal health always outweighs trends or hearsay from social media.

Researchers and manufacturers keep looking for new options that match dibutyl adipate’s performance but might skip rare reactions entirely. Brands pushing for “clean” or “natural” formulas consider these alternatives, though not all deliver the same smooth feel or shelf-life. It pays to remember that even so-called “natural” products can bring up their own issues.

Dibutyl adipate feels like the quiet type found in many laboratories and manufacturing plants. This clear, almost invisible liquid has a faint, sweet scent and shows up mostly because someone needs things flexible, soft, or resistant to the elements. With a molecular formula of C14H26O4, its build reveals a compound made of adipic acid combined with two butyl alcohol molecules. Nothing flashy—just reliable chemistry at work.

Pour dibutyl adipate, and you’ll notice its oily texture right away. Its boiling point floats around 340°C, so it sticks around under tough heat. It won’t freeze over quickly either—the freezing point hangs around minus 32°C. If you spill some, you’ll see it spreads easily, and the viscosity stays fairly low, which helps in blending it into other liquids or pastes. In water, dibutyl adipate shows stubbornness; it won’t dissolve much—less than 0.5 grams in a liter. This property keeps it stable and stops it from washing away in applications exposed to moisture or humidity.

Anyone dealing with plastics or rubbers values that low volatility. The vapor pressure is minimal, so it holds its place without evaporating quickly. Because its flash point is above 170°C, it’s not eager to catch fire, which counts for safety in shops and plants. With a density a bit less than water—about 1.05 g/cm³—you could see it float subtly. That balance helps as a blending agent in crafting coatings, adhesives, or nail care products.

Dibutyl adipate brings a mild, forgiving nature. It resists breaking down under normal temperatures but won’t fight extreme alkaline or acidic systems. Sunlight or strong oxidizers over time will wear it down, but otherwise it stays put. With its straight-chain structure, the molecule doesn’t let in heavy metals or reactive impurities—so it doesn’t become a troublemaker in finished goods.

Plastics manufacturers count on dibutyl adipate as a plasticizer, especially in PVC where flexibility is the goal. Picture clear tubing, synthetic leathers, or floor tiles—dibutyl adipate delivers the bend without leaving stains or strong odors. The food packaging field sometimes draws on it, but regulations in the US and Europe put limits on amounts, especially if food comes in contact with the finished material. In cosmetics, the substance helps nail polishes dry smoothly and flex with movement. Those making pesticides or repellents trust its ability to carry active ingredients and resist water wash-off.

No one should underestimate basic chemical hygiene even for mild-mannered compounds. Dibutyl adipate might cause mild irritation if handled carelessly, so gloves and eye protection make sense in the workplace. From a health risk view, studies have shown low acute toxicity, meaning unusual exposure doesn’t usually create severe effects. Long-term or chronic impact hasn’t raised big alarms, but policies lean on the side of caution, keeping exposure as low as possible.

As environmental pressure grows, many companies consider the whole lifecycle. Dibutyl adipate biodegrades slowly, which reduces risk in groundwater, but it’s smart to avoid dumping waste down drains. Recycling or controlled incineration prevents build-up in soil or water sources. Moving to biodegradable alternatives and closed-loop processing wins favor among regulators and community watchdogs alike.

It helps to know what sits in your raw materials list, especially if you work in plastics, coatings, or even cosmetics. Understanding dibutyl adipate’s character guides teams to harness its benefits while respecting safety and environmental balance. The substance rarely grabs headlines, but it helps keep many products in shape, day in and day out.

Anyone who’s worked around industrial chemicals knows smart storage isn’t about paranoia. It’s about respect—for the people on the floor, for the equipment in the shop, and for whatever job comes next. Dibutyl adipate’s main use shows up in plastics, coatings, and sometimes cosmetics. In my years handling hazmats in a warehouse, I learned that skipping basic steps causes trouble much faster than most imagine, especially when it comes to liquid ester compounds.

Dibutyl adipate keeps a stable profile at room temperature, but that doesn’t give a green light to treat it like tap water. I’ve seen old storerooms with scorched patches along the wall after summer heat or freezing winters damaged stored drums. Persistent heat risk includes fire and unexpected pressure inside containers. Cold brings thickening or solidification, maybe even barrel seals failing and causing messy cleanups. Industry best practice recommends a controlled indoor temperature, typically 15–30°C (59–86°F). Steer clear of furnaces, direct sunlight, or outdoor sheds where temperature swings drive up risk.

Industrial plastics or steel drums that fit chemical compatibility charts hold dibutyl adipate well. In the field, I’ve seen workers improvising with random containers, hoping to cut costs, and almost always regretting it when corrosion or leaks appeared. Weak seals and chemical reactions with unapproved liners only mean headaches—potential exposure, property loss, fines, or worse. Stick to containers designed for esters. Every container should be sealed tightly with undamaged lids and gaskets. Drips or residue shouldn’t be visible on the threads or around the valve.

Moisture turns a stable chemical into something unpredictable. In older factories I visited, ignoring damp floors and rusty shelves caused cross-contamination—wasting valuable product and triggering safety incidents. Store dibutyl adipate in a dry area away from all water sources and acids, since hydrates and strong oxidizers speed up unwanted breakdown or even cause a dangerous reaction. Labeling and separating esters from incompatible materials prevents confusion and makes routine auditing smoother.

You don’t want to inhale concentrated vapors during transfer or sampling. Shops I worked at relied on good ventilation and source extraction fans right at drum filling stations. Not every plant skips open-top funnels, so make sure team members use gloves and splash goggles, as outlined in OSHA’s guidelines, especially if product splashes or evaporation occurs. A little prevention goes a long way. Skin contact can lead to irritation, and no one appreciates an avoidable chemical burn.

No storage or handling can guarantee zero accidents, so responsible outfits keep spill kits, fire extinguishers, and eyewash stations within reach. Quick response means smaller spills, less panic, and far less downtime. In places following EPA and OSHA advice, regular drills and safety briefings pay off if a forklift goes off course or a container springs a leak.

Every product on the safety data sheet deserves respect. Dibutyl adipate won’t explode on its own, but careless storage or rushed transfers set up trouble. From sticking with reliable containers to posting clear labels, the choices made on the warehouse floor show whether a company values worker health and product integrity. Small steps stack up to a safer workplace, and past mistakes remind anyone who’s handled chemicals that it pays to stay consistent.

Dibutyl adipate pops up on labels for sunscreens, nail polish, and even plastic items around the house. Companies say it boosts flexibility or spreads smoothly on skin—features manufacturers look for in personal care and plastics. The real question, though, centers on what happens to this substance once it floats out of the factory and into the world. Does it stay in soil and water, or does it break down into something safer for people and wildlife?

Plenty of marketing mentions “biodegradable”—but that word gets tossed around so much, it can lose meaning. Some chemicals take years to vanish in nature, even if they technically break down. In the lab, researchers ran tests with dibutyl adipate in both soil and water. They checked whether natural bacteria could chop it up for food. Results showed that, under ideal conditions, bacteria do a decent job—especially in water. The compound splits into butanol and adipic acid. Both parts go away quickly in active, healthy soil and water where bacteria thrive.

Problems crop up when banking on “ideal conditions.” Everyday landfills pack waste tightly, shutting out air. Rivers, lakes, and soil sometimes get overloaded with pollution, throwing off this breakdown. In cold climates or contaminated places, dibutyl adipate can stick around a lot longer—sometimes for months or even longer, depending on the environment’s health.

People care about more than just speed of breakdown. I care about what the chemical breaks down into. Studies show the byproducts don’t linger in living creatures or build up as toxins. That’s a relief. Still, big spills can overwhelm streams and cause fish or bugs to suffer a short-term hit, especially if water isn’t moving fast enough to dilute it.

Some tests in labs suggest fish and tiny aquatic animals only show effects at high doses—far above what’s found in most polluted waterways. Workers in factories handling the stuff day in and day out need to pay more attention than folks using sunscreen.

Recycle bins and compost piles find little use for dibutyl adipate in plastics or coatings. Products end up in garbage or wash down the drain with wastewater. In modern sewage facilities with good filters and bacteria, the chemical mostly breaks down before reaching rivers. Regions without strong waste treatment see more dibutyl adipate in streams, which can add up over time though levels rarely spike dangerously.

Plenty of other plasticizers and similar ingredients hang around much longer or build up inside animals. That matters to me—as someone who wants playgrounds, parks, and rivers clean enough for my family and the local wildlife. Still, “greener” does not mean “harmless.” Frequent use across industries means even a quick-breakdown substance like dibutyl adipate could add to bigger pollution problems if waste management slips.

Safer replacements for old-school plasticizers like phthalates put dibutyl adipate on the preferred list for companies wanting to cut down on toxic risks. Swapping one chemical for another always brings new questions. Keeping updates flowing from scientists, health agencies, and waste workers helps communities spot issues before they grow.

Small choices, such as tightening rules on sewage and landfill leaks, using cleaner feedstocks, and making sure recycling plants stay funded, have real impact. I’ve seen how communities with better infrastructure cut down on all sorts of chemical pollution. When citizens push for more public reporting and companies open up about testing results, no greenwashing survives the daylight.

| Names | |

| Preferred IUPAC name | Di(butyl) hexanedioate |

| Other names |

DBA Dibutyl hexanedioate Adipic acid dibutyl ester Butyl adipate |

| Pronunciation | /daɪˈbjuːtɪl ˈædɪpeɪt/ |

| Identifiers | |

| CAS Number | 105-99-7 |

| Beilstein Reference | 0608733 |

| ChEBI | CHEBI:31923 |

| ChEMBL | CHEMBL3182320 |

| ChemSpider | 54613 |

| DrugBank | DB02650 |

| ECHA InfoCard | 100.007.436 |

| EC Number | 204-652-9 |

| Gmelin Reference | 77877 |

| KEGG | C19609 |

| MeSH | D006383 |

| PubChem CID | 3026 |

| RTECS number | AF7350000 |

| UNII | 6B0J2BYR1O |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C14H26O4 |

| Molar mass | *258.38 g/mol* |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 1.02 g/cm³ |

| Solubility in water | Insoluble |

| log P | 4.42 |

| Vapor pressure | 0.1 mmHg (25°C) |

| Acidity (pKa) | 10.24 |

| Magnetic susceptibility (χ) | -7.56e-6 |

| Refractive index (nD) | 1.444 - 1.446 |

| Viscosity | 15.6 mPa·s (25°C) |

| Dipole moment | 2.42 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 589.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -726.15 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3912.1 kJ/mol |

| Pharmacology | |

| ATC code | D11AX10 |

| Hazards | |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H317: May cause an allergic skin reaction. |

| Precautionary statements | Wash thoroughly after handling. Wear protective gloves/eye protection/face protection. If skin irritation occurs: Get medical advice/attention. If skin irritation or rash occurs: Get medical advice/attention. |

| NFPA 704 (fire diamond) | 1-1-0-N |

| Flash point | 170°C |

| Autoignition temperature | 355 °C |

| Lethal dose or concentration | LD50 oral rat 9000 mg/kg |

| LD50 (median dose) | 11 g/kg (rat, oral) |

| NIOSH | NA8340000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Dibutyl Adipate: Not Established |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Adipic acid Diethyl adipate Dimethyl adipate Dioctyl adipate Bis(2-ethylhexyl) adipate |