The journey of Triethylene Glycol Methyl Ether Borate doesn’t start in a vacuum. Chemists in the post-war push for novel borate esters often found themselves chasing new materials with unique solvating powers. Old literature describes labs transforming basic borate compounds by introducing glycol chains, a process that demanded both patience and plenty of creative troubleshooting. Not every attempt paid off, especially during those years when glassware and pure reagents weren’t nearly as advanced as they are now. But persistence paid off as researchers finally nailed down scalable approaches. From early patent filings in the late 1960s to more routine industrial production in the 1980s, the story reflects the usual muddling through — failed reactions, unexpected precipitates, heat runs, and countless pH tests — that eventually led to this compound’s reliable synthesis.

Triethylene Glycol Methyl Ether Borate falls into a class of boron-based esters that bridges organic solvents and effective complexing agents. This material doesn’t look flashy on paper, but its value turns up in those trickier applications where typical glycols or borates hit a wall. Whether someone is preparing specialty lubricants or modern functional fluids, this product steps up with real-world reliability. Its structure pairs the stability of boron centers with long ether chains, so it draws a technical crowd looking for more than just your everyday solvent.

The liquid form tells its own story. With a faint, sweet aroma and clarity that rivals any high-grade glycol ether, you get the sense this is a well-behaved compound. Its molecular weight sits around 357 g/mol, offering a nice balance between volatility and stability. Boiling and freezing points fit within working ranges for chemical processing — no nasty surprises halfway through a reaction run. Its viscosity is moderate, not too thick or runny, so handling and mixing don't create headaches for operators. Solubility feels almost tailored for polar and mildly nonpolar blends, and it resists hydrolysis better than some relatives, thanks to the stabilized borate group. Electrical conductivity hangs low, making it a quiet performer in specialized electrolyte formulations.

Manufacturers stick to clear labeling, for good reason — trace impurities in borate esters spell trouble in sensitive applications. Purity typically runs above 98%. Water content lands well below 0.5%, since any more could foul up the most demanding syntheses. Standard specs read like a checklist: refractive index, density at 20°C, GC assay, and heavy metal screening. Shipping drums come labeled with hazard warnings for skin and eye contact, as the borate component demands respect from anyone on the shop floor.

The main production method involves reacting triethylene glycol methyl ether with boric acid or boron trifluoride under controlled temperature and moisture conditions. A professionally run plant doesn’t cut corners — dry nitrogen, clean glassware, and skillful addition of reactants all keep the reaction on track. Water, one of the main byproducts, gets removed continuously with vacuum or azeotropic distillation, keeping the equilibrium favorable. The resulting mixture passes through multiple purification steps: filtration, vacuum stripping, and sometimes a finishing distillation, depending on the application grade required. Lab and pilot-scale setups often reveal purification bottlenecks that only scale with additional investment, echoing the perennial gap between bench chemistry and true manufacturing.

Once synthesized, this borate ester stays chemically robust under typical handling, though strong acids and bases can split it apart. In real use, the molecule acts as a ligand for transition metals, sometimes helping to solubilize metallic salts when nothing else in the toolbox seems to work. Modifications often start by swapping the glycol side chain for analogues or tweaking the borate center itself; these changes shift boiling points, alter coordination behavior, and open up new application options. A lab equipped for functional group swaps can turn this raw material into tailored reagents for catalysis or advanced coatings.

Chemists rarely stick to one label, and this compound’s identity often hides in synonyms like TEGMEB, Triethylene Glycol Monomethyl Ether Borate, or just “glycol borate ester” on older datasheets. Commercial outfits may assign house codes or branding, sometimes for legal reasons, sometimes just for competitive advantage. Among suppliers, a dose of confusion always lingers from catalog to catalog, so anyone ordering bulk should double-check the molecular formula to avoid shipping the wrong product — it happens more than folks admit.

Regulatory teams classify this borate ester with caution due to moderate toxicity. Handling calls for basic PPE — gloves, splash goggles, lab coats — as skin and mucous membrane exposure lead to unpleasant and sometimes persistent irritation. Inhaling vapors or aerosols over a working shift feels rough on the respiratory tract, so good ventilation or local exhaust systems aren’t optional. In fire scenarios, decomposition products can release boron oxides and glycol fragments, which means fire crews need advanced respiratory protection. Proper storage avoids humid conditions and prevents container corrosion. Updated SDS documents give frontline workers what they need to stay safe; skipping these steps quickly turns minor errors into medical emergencies.

This borate ester crops up in niches that care about solvency and coordination — think battery electrolytes, high-performance lubricants, polymer stabilizers, and custom syntheses. The value shows up not just in what it does, but in how it lets chemists push past the limits of ordinary glycols and borate salts. Electronic component manufacturers like its dielectric properties and stable behavior at elevated temperatures. In the world of metalworking, it serves as a rust inhibitor and fluid additive, stretching tool life in industrial plants. Academic research teams experiment with it as a catalyst support or as a component in novel organic synthesis routes, hoping to unlock new reactivity by tuning the structure. Not every application stands up under commercialization pressure, though, and plenty of hopeful developments never move off the lab bench.

Over the past decade, funding agencies have nudged chemists to reexamine borate esters, especially in energy storage and advanced manufacturing. Teams across Europe, North America, and East Asia have tinkered with structural analogues, searching for versions that resist hydrolysis or offer stronger metal chelation. Papers in the last five years document synergistic effects with ionic liquids or nonaqueous solvents in battery systems, aiming for longer cycle life and safer operation. Research partnerships between universities and industry have pressed for more scale-up data, since pilot plants often suffer hiccups not seen in small flasks. The patent literature reflects a burst of interest but also a heap of dead ends — lots of compounds promise the moon, few deliver at a price manufacturers can swallow. Yet the curiosity remains, as incremental improvements here fuel broader changes in functional materials.

Animal studies reveal moderate toxicity, especially in cases of prolonged inhalation or repeated dermal contact. Acute exposures trigger inflammation, headaches, and in rare cases, systemic effects on the liver or kidneys. Regulatory scientists flag possible reproductive risks from long-term boron exposure, though studies disagree on the degree of human concern, keeping the debate alive. Researchers track breakdown products in soil and water, watching for any hint of persistence or bioaccumulation, even though the molecule generally degrades faster than many legacy solvents. Safety datasets grow fatter each year as chemical risk management turns from backroom paperwork to public accountability.

Shifting to greener chemistry and tougher tox limits, demand pushes for borate esters that both perform and degrade with minimal fuss. Researchers eye approaches that lower synthesis energy or cut hazardous byproducts. The hunt continues for ways this molecule could feed into next-generation electrolytes, sustainable coatings, or biocompatible materials. Old habits in manufacturing slow down adoption, but small startups sometimes swing for bold moves before bigger firms catch up. As climate goals take center stage, the material’s future may hinge on how well it balances technical performance with environmental stewardship.

Triethylene glycol methyl ether borate doesn’t show up in splashy headlines, but its role inside manufacturing, electronics, and specialty fluids quietly shapes the final products we use every day. I remember a call with a chemical supplier, who half-joked that nobody outside the lab can pronounce these words—yet he could point to at least five items on my desk that rely on them to function. Not all compounds deserve the spotlight, but this one does more behind the scenes than most folks would guess.

In lithium battery research, finding safe and effective electrolytes remains a tough challenge. Triethylene glycol methyl ether borate gets attention from battery engineers for its stable properties. It helps keep electrolyte solutions from breaking down under the heat and electrical load of daily use. I’ve seen papers out of Japan and the U.S. where researchers push for higher-capacity batteries using this borate compound in their formulations, aiming to keep energy storage both stable and safe—even after hundreds of charge cycles.

Grease might not sound like the future, but the world runs on smooth machinery. Lubricants with triethylene glycol methyl ether borate in the formula offer improved protection for metal parts under high stress or temperature fluctuations. Old gearboxes in industrial settings, especially, benefit from additives that help manage moisture and cut down on oxidation. After seeing maintenance budgets blown sky-high by rusted bearing failures, engineering teams started leaning on better chemical blends—this borate ester among them. Shortening unexpected downtime becomes possible, mostly thanks to simple chemistry.

Modern chemistry usually relies on solvents that don’t interfere or break down under tough conditions. This compound stands out for its ability to dissolve polar and non-polar substances, making it handy in specialized coatings and adhesives. A formulation chemist once told me their team saved months of work by switching to this borate compound to get a custom polymer to set right. Sometimes it’s the overlooked solvent that unlocks a whole market for flexible electronics or advanced adhesives that stick without mess or residue.

In places where flammable hydraulics spell disaster, fluids mixed with borate esters provide a safety net. Heavy equipment in steel mills or mining operations can’t tolerate a slip in fire resistance. Regulations around safety keep tightening, and companies look for fluid additives that don’t just meet the standard, but exceed it by giving more peace of mind to the folks working near red-hot machinery. The push for safer industrial fluids keeps this chemical on many buyers’ shortlist.

Handling these chemicals doesn’t come trouble-free. Anyone who’s spent time in a lab or plant knows spills, fumes, and improper disposal threaten health and the environment. Training workers to handle even small doses correctly, plus keeping venting and disposal systems up to snuff, becomes crucial. Some manufacturers have started publishing full-life cycle information on additives like this, hoping a push for transparency will cut risky shortcuts. Investing in safer packaging and education works better than betting on good luck.

Triethylene glycol methyl ether borate may never hit the consumer radar, but batteries, equipment, and adhesives all stand taller because it does its job. Industry pushes forward only when folks on the front lines—technicians, engineers, chemists—work with materials that balance performance and safety. Giving quiet contributors like this borate compound a little credit helps shine the light on what really makes progress possible.

Triethylene Glycol Methyl Ether Borate isn’t some innocent liquid you can leave out in the open. My experience around industrial solvents tells me this one needs real respect. Even before looking at chemical hazard documents, the strong chemical odor already sends a message—protect yourself. This substance bites skin, irritates eyes, and doesn’t mix well with lungs. If you just grab a pair of thin gloves and think you’re good, you’ll regret it fast. Thick nitrile gloves matter; goggles keep splashes from turning into medical emergencies. I’ve seen people skimp on protective gear, thinking it’s overkill. Ten minutes later, they’re scrambling to wash off a burning rash.

People sometimes treat ventilation like a box to check. That’s a mistake. Walk into a room treated just with a table fan, and the vapors stick around. Over time, breathing them leads to coughing, sore throat, and headaches—not a surprise since Triethylene Glycol Methyl Ether Borate can mess with your respiratory system. Proper local exhaust systems—fans that pull fumes right at their source—make all the difference. If you ever stepped into a lab with good air movement, you can work all day without feeling it in your lungs.

Leaving this chemical in a random closet or near flammable materials invites trouble. This stuff reacts with moisture and heat. I once worked in a place where someone left it near a heat vent; the result was cracked containers and a not-so-minor cleanup job. Leak-proof containers in cool, dry storage save nerves and dollars. Shelving with lips and spill trays helps too, especially if you care about the floor—or the people walking by.

A small spill of Triethylene Glycol Methyl Ether Borate turns into a mini crisis if ignored. Dash over with absorbent pads, throw on gloves, and sweep it up while it’s manageable. I’ve seen folks grab paper towels in a panic, spreading it further. Using proper cleanup materials stops contamination on the spot. Disposing of rags and spill debris in a sealed bin, not the regular trash, keeps janitors and coworkers safe. Nobody deserves a rash or worse from someone else’s shortcut.

I’ve attended safety training after safety training, and the message always lands the same: labels save lives. Knowing exactly what you’re dealing with keeps accidents at bay. Every bottle marked, every safety sheet posted, every worker briefed—these steps cut down on “I didn’t know” moments. I’ve watched new staff misjudge a bottle, only saved by a big, clear label. It’s not overkill, it’s common sense.

Some folks might think pouring leftovers down the drain is no big deal. Big mistake. Waste contractors exist for a reason—Triethylene Glycol Methyl Ether Borate doesn’t belong in water supplies or the trash. I know it’s extra paperwork and some red tape, but putting it in a labeled waste drum saves a lot of headaches with environmental inspectors and keeps groundwater safe. I’ve stood at collection centers, watching the right chemicals get hauled off with zero drama rather than risking a fine or pollution.

Respect for chemicals like this doesn’t come from fear—it comes from seeing what small mistakes can do over time. Staying cautious—wearing the right equipment, labeling every bottle, using spill kits, locking up containers, getting rid of waste the right way—keeps both the workplace and the environment out of trouble. Safety isn’t a one-time box to check. It’s a habit that pays off every single shift.

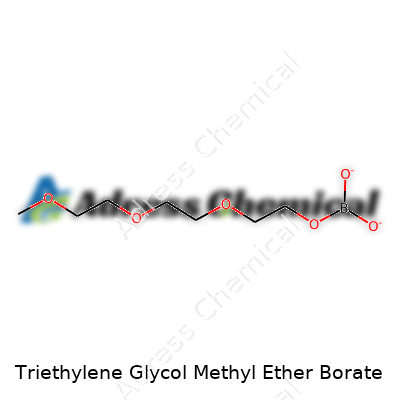

Triethylene Glycol Methyl Ether Borate isn’t a compound you’ll find grabbing headlines, but it pops up in certain technical circles. You can trace its name right back to the chemistry behind it: triethylene glycol methyl ether forms the backbone, while borate gives it a functional twist. The chemical formula for this compound is often listed as B(OCH2CH2OCH3)3. On paper, this means three arms of triethylene glycol methyl ether are hooked up to a boron atom.

This molecule looks like a pinwheel. One boron atom sits at the center, with three branches spinning out, each one built from methyl ether and ethylene glycol units chained together. Picture each branch: CH3OCH2CH2OCH2CH2O-. All three wrap around one boron atom in a tight, controlled setup. That pattern isn’t just for show—the structure gives the molecule a mix of flexibility and coordination chemistry that makes it useful in specific industrial applications.

Chemistry classes rarely dwell on chemicals like this, but triethylene glycol methyl ether borate has talents that bring value in the real world. Take the electronics industry—borate esters like this get called up because of their high stability and ability to shuttle ions around. For someone like me who’s handled electrolytes and solvents in a research lab, that translates to longer battery life, cleaner circuit boards, and more robust lubricants. Folks at the workbench know that the little quirks in a compound’s structure often make or break performance. That three-armed, shielded arrangement gives this molecule low volatility and high chemical compatibility, making it easier to handle, safer to use, and less likely to leave unwanted byproducts.

Anytime you mix organic ethers with boron compounds, chemical safety and sourcing come into play. In my experience working with similar esters, gloves and fume hoods aren’t just suggestions—they’re essentials. It’s easy to overlook small hazards when buried in technical specs, but the combination of glycol ethers and boron needs careful control to avoid exposure and environmental spills. Manufacturing this borate ester takes steady hands, clean glassware, and patience. Boric acid or boron oxide gets reacted with triethylene glycol methyl ether, removing water as the ester bonds form. Even a trace of leftover water messes with the product, so dry conditions always win the day.

It’s easy to get caught up in high-tech performance, but there’s more ground to cover in making triethylene glycol methyl ether borate truly sustainable. Rather than relying on fossil-sourced components, greener feedstocks should play a bigger role. Finding better methods to recycle or reclaim this compound after use would cut down on waste and chemical risk. From a bench chemist’s view, shifting toward closed-loop processes and using less hazardous catalysts would move the industry forward. If those changes land, the compound could keep its proven advantages while shrinking its footprint.

Triethylene glycol methyl ether borate might never make mainstream news, but the chemistry tells a bigger story. Its design solves practical problems in factories and labs, even as supply chains and regulations keep changing. I’ve watched new approaches catch on quickest not through top-down mandates, but through hands-on trial and error—tweaking structure, workflow, or upstream materials until costs drop and safety climbs. For chemists and engineers, getting the formula right is just the start; everything after depends on understanding both the science and the setting where it gets put to use.

Triethylene Glycol Methyl Ether Borate sounds technical, but it’s a chemical many people run into in labs and manufacturing spaces. This compound isn’t as widely recognized as something like acetone or bleach, but it stands out for properties that call for care in storage. Many users treat storage as an afterthought. That attitude can cost a company not only in financial terms but also in health and environmental safety slips.

People often shrug at official warnings, thinking of them as red tape. In practice, I’ve seen what can happen if someone leaves bottles of a solvent on an open shelf or lets the wrong vapor loose into the air. Triethylene Glycol Methyl Ether Borate won’t give you an immediate reason to panic on contact, but it doesn’t belong in a place where it can mix with moisture, heat, or reactive materials. If the storage room doesn’t block sunlight, or the temperature bounces around with the seasons, the chemical can change in ways that nobody wants. Even sealed containers can leak, given enough time and the wrong conditions.

I once helped set up a new storeroom for specialty chemicals. What struck me was the planning that goes into choosing a spot: away from direct heat sources, away from traffic, away from other chemicals that could react if there’s a spill. Triethylene Glycol Methyl Ether Borate belongs in a cool, well-ventilated room. Humidity brings trouble; water vapor in the air can mess with some borate compounds, leading to slow breakdown or even pressure inside containers. Metal shelving sounds sturdy, but it’s better to pick up shelves with a coating that resists corrosion, since borates and moisture together can turn a solid rack into rust over time.

Most containers come with labels, but human nature means not everyone checks dates or condition of packaging. Regular inspections help spot leaks, bulging, or fading labels long before disaster strikes.

A big part of safe storage means thinking beyond one bottle or box. I’ve seen little things — like missing spill trays, crowded shelves, or forgotten labeling — turn minor mistakes into major headaches. Store Triethylene Glycol Methyl Ether Borate only in original, tightly sealed containers, ideally the kind made for chemical resistance. Leave space between bottles, just in case, and add absorbent liner pads to shelves. By storing only the amount needed, and keeping it segregated from strong acids and oxidizers, the risk of weird chemical reactions drops down.

One item often left off safety lists is up-to-date documentation. Even a small handwritten sign, stating who last checked the chemicals, can keep everyone honest. I once saw a storeroom with decades-old stock — nobody knew what was back there. That points to the need for simple logging processes: write down arrival dates, quantities in storage, and regular inventory audits.

Many companies have moved to automated storage tracking. Barcodes and scanners work wonders for keeping tabs, especially in large operations. For smaller labs, a whiteboard or spreadsheet can do the job. Training matters just as much; nobody should handle or move Triethylene Glycol Methyl Ether Borate unless they know exactly what’s in those bottles and how to clean up if something goes wrong.

Personal experience shows that change starts with making safety an everyday habit. Walk into a well-run chemical storage area, and you’ll see clear signs, good lighting, and staff who take pride in keeping hazards locked down. That kind of environment leads to fewer accidents and longer-lasting, more reliable chemicals — something that just feels better for everyone involved.

Talking about chemicals, names tend to get long and intimidating. Triethylene Glycol Methyl Ether Borate falls right in that category. It’s used for special industrial purposes – think areas like batteries, lubricants, and advanced plastics. I remember skimming through safety data sheets at a tech lab and seeing a mouthful like this on inventory labels, always wondering if I should wear extra gloves.

Looking through the main sources — chemical manufacturers, safety regulators, and databases like PubChem — the first thing that pops up is limited hazard data. This isn’t a household chemical, so it doesn’t get much mainstream attention. Not every chemical with a scary-sounding name keeps people up at night, but it pays to be cautious if it lands in your workplace. Generally, similar glycol borates may cause eye and skin irritation, and you wouldn’t want to breathe in vapors. I once saw a colleague handle a glycol ether compound without goggles; he paid the price with stinging eyes and an afternoon in the wash station. Stories like that stick with you.

If a chemical poses big risks, agencies like OSHA or the EPA set official rules. Still, this one usually doesn’t appear in the main lists that flag serious or acutely toxic materials. The US Toxic Substances Control Act tracks a huge number of industrial chemicals, but not all earn special restrictions. In Europe, REACH sometimes tags these glycols for reporting requirements because of possible environmental or health impacts. Even if a chemical isn’t on a no-go list, labs and factories treat it with respect — gloves, goggles, and fume hoods are standard. Ignoring the safety basics leaves you open to issues, even with less-publicized chemicals.

Most people won’t run into Triethylene Glycol Methyl Ether Borate much. But the larger question holds up: how well are all the specialty chemicals tracked and tested? History keeps offering up sad reminders — think of leaded gasoline sticking around for decades. The challenge comes from the sheer number of synthetic compounds. It isn’t always possible to spot trouble before it shows up. That means we rely on manufacturers and workplaces to build in safety, not just scramble after a headline shows up.

If a workplace handles this borate, regular training goes a long way. I’ve learned that simple procedures, like labeling every bottle and having up-to-date data sheets within arm’s reach, help more than fancy warning signs. Workers need real reminders, not just stacks of binders sitting dusty on a shelf. Ventilation, personal protective equipment, and spill control supplies on hand all matter — I saw a minor spill in a plant get contained in seconds because somebody cared enough to keep the right gear on a cart by the door. Regular audits and honest reporting culture help catch problems early.

Stronger oversight comes from updating chemical inventories, supporting continued research on lesser-known substances, and encouraging industry to swap out toxic components if safer ones exist. These steps keep both workers and neighbors out of harm’s way. It boils down to not treating any chemical with blind trust — routine care, updated knowledge, and a dash of caution go a long way.

| Names | |

| Preferred IUPAC name | 2-[2-(2-Methoxyethoxy)ethoxy]ethyl borate |

| Other names |

Boronic acid, B-(2-(2-methoxyethoxy)ethoxy)- Triethylene glycol monomethyl ether borate Boric acid, tris(2-(2-methoxyethoxy)ethyl) ester |

| Pronunciation | /traɪˈɛθaɪliːn ˈɡlaɪkɒl ˈmɛθəl ˈiːθər ˈbɔːreɪt/ |

| Identifiers | |

| CAS Number | [30989-05-8] |

| 3D model (JSmol) | `3D model (JSmol)` string for **Triethylene Glycol Methyl Ether Borate**: ``` COCCOCCOCCOB(O)(O)O ``` |

| Beilstein Reference | 2698736 |

| ChEBI | CHEBI:131756 |

| ChEMBL | CHEMBL1906753 |

| ChemSpider | 20410368 |

| DrugBank | DB11277 |

| ECHA InfoCard | echa.europa.eu/substance-information/-/substanceinfo/100.118.496 |

| EC Number | 939-427-4 |

| Gmelin Reference | 10742 |

| KEGG | C18430 |

| MeSH | D015242 |

| PubChem CID | 10216869 |

| RTECS number | TN9450000 |

| UNII | 7A4E496U2N |

| UN number | UN3334 |

| CompTox Dashboard (EPA) | DTXSID1040647 |

| Properties | |

| Chemical formula | C11H27BO7 |

| Molar mass | 222.06 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 1.14 g/cm3 |

| Solubility in water | Miscible |

| log P | -1.1 |

| Vapor pressure | <1 mmHg (20 °C) |

| Acidity (pKa) | 8.2 |

| Basicity (pKb) | 8.34 |

| Magnetic susceptibility (χ) | -59.0 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.437 |

| Viscosity | Viscosity: 6.2 mPa·s (25°C) |

| Dipole moment | 3.63 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 528.4 J·mol⁻¹·K⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302: Harmful if swallowed. H319: Causes serious eye irritation. |

| Precautionary statements | P264, P280, P305+P351+P338, P337+P313 |

| Flash point | 110°C (230°F) |

| Autoignition temperature | 210 °C |

| Lethal dose or concentration | LD50 (oral, rat): >2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: 5,200 mg/kg |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 mg/m3 |

| Related compounds | |

| Related compounds |

Triethylene glycol methyl ether Boric acid Triethylene glycol Methyl borate |