Safety Spotlight: New Insights into the Occupational Hazards of Dipropylene Glycol Methyl Ether

The Chemical Behind Countless Workdays

Dipropylene glycol methyl ether, or DPGME, sounds like something tucked away in a lab, but the truth is it quietly powers many of our workspaces—from factories to print shops, even cleaning products at your local grocery store. Folks might not stop and think about the liquid in their hands, but the scientists digging into DPGME's impact now have a lot more to say, and it goes far beyond the frozen facts on a product safety sheet. Many workers spend years exposed to this solvent, without much say in how it shapes their skin, their breathing, or their long-term health.

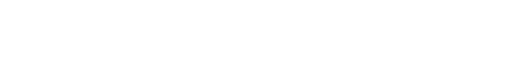

One Chemical, Many Paths Into the Body

Open a bottle, splash a bit or breathe just a faint whiff in a tight room, and DPGME finds its way in. Factory jobs often involve skin contact, but it's the slow buildup in a poorly ventilated area that lingers in people's bodies. Breathing issues tend to sneak up. I’ve seen old coworkers develop red, itchy hands, or rub their eyes with a puzzled frown—only to pass it off as “just part of the job.” The real hazard isn’t always dramatic: headaches that just won’t quit, tight lungs after a long shift, odd patches of skin. Safety data since 2022 points to DPGME as more than just an irritant; there's mounting evidence workers exposed day in and day out face subtle shifts in liver and kidney function. That’s not scare tactics. It’s what routine blood work, compared in new studies, is now showing.

Workplace Culture and Overlooked Risks

Factory floors rarely see big overhauls unless someone pushes for it. Supervisors may post a faded chart with warnings, but without recent info making the rounds, employees tend to stick with old habits. Gloves might sit unused because they feel awkward, or ventilation systems hum in the background but don’t meet the latest standards. Rushing through a cleaning job before closing time, workers grab whatever is closest, often skipping the right safety mask. The assumption goes: if nobody’s collapsed yet, the danger must be low. In truth, some of the worst health changes go unnoticed for years. People deserve more than a shrugged-off warning, so the conversation about DPGME demands life-sized examples, not just numbers on a bulletin board.

Why Masking Up and Gloves Make a Real Difference

Small changes can cut real risk. I’ve watched teams scoff at thicker gloves, but after our crew leader took a chemical safety demo to heart, wearing those gloves and swapping out thin ones became routine. Workers stopped shaking their heads at eye shields after hearing about a local worker’s trip to the ER. Regular breaks, better airflow, and good training don’t show up in the bottom line, but they show up in better health numbers a couple of years down the road.

Solutions Don’t All Come in a Bottle

Companies need more than a shipment of new protective gear—they must update buy-in from everyone. I’ve found the best changes come about when workers take the lead. Peer-to-peer reminders make more sense than a droning lecture. Regular health checks that coworkers trust bring out honest stories. Team leaders who listen and make time for real feedback transform safety from a rule into a habit. Employers stand to gain, too; missed work from illness, long-term claims, and high turnover all cut into productivity much more than a box of extra gloves ever could.

The Next Step: Healthy Work, Decent Work

DPGME is here to stay for the foreseeable future. But just ignoring new data or treating symptoms without digging into root causes won't cut it. Companies willing to review their chemical handling policies, trainers revising material based on new research, and workers who treat safety gear as essential, not optional, set a new bar for what safe work should look like. Having seen small changes lead to healthier crews, I know it’s worth pushing for better. Rolling out fresh training, sharing the latest studies, and giving folks real reasons to care pays off for everyone, from line workers to top bosses.

Compliant Production

Compliant Production Proven Processes

Proven Processes Reliable Supply

Reliable Supply Standardized Workflow

Standardized Workflow